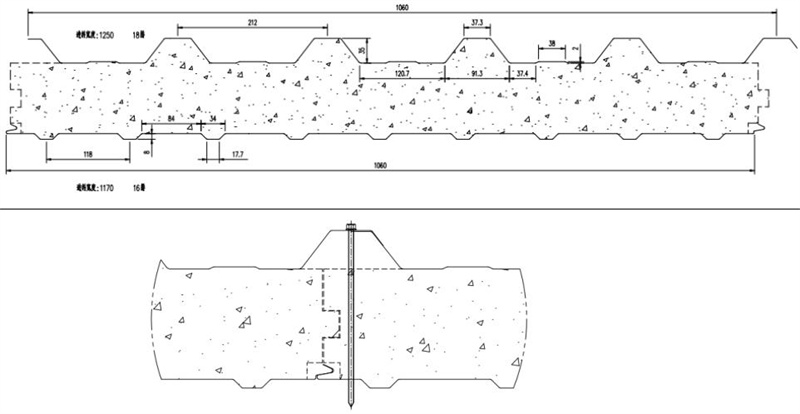

Full-Automatic T18/T35 IBR Roofing Sheet Roll Forming System with Dual-Layer Capability

This advanced roll forming line enables fully automated production of European-standard profiled sheets, including C8, C25, T18, T35, C44, and T44 configurations tailored for Russian and Hungarian markets. Engineered for structural versatility, the system manufactures both single-layer and double-layer roofing/wall cladding panels with precision tolerances.

T18 T35 Ibr Roofing Sheet Roll Forming Machine

| Coil technical parameters | ||

| Series | Details | Parameter |

|

Product sheet |

Raw material | GI&PPGI |

| Material thickness | 0.25-0.8 mm | |

| Feeding width | As request | |

| Sheet cutting length | Adjustable | |

| Packing list-roof profile machine | ||||

| No. | Name | Unit | Quantity | Remark |

| Part 1 | 5T manual decoiler | set | 2 | manual |

| Part 2 | Guide feeding device | set | 2 | With hand cutter |

| Part 3 | Main roll former | set | 2 | Chains drive |

| Part 4 | PLC control station | set | 2 | Delta brand |

| Part 5 | Cutting system | set | 2 | Hydraulic |

| Part 6 | Hydraulic oil pump station | set | 2 | With cooling fan |

| Part 7 | Product collect table | set | 2 | Regular type/3m length |

| Part 8 | Spare parts | set | 2 | |

Option A: Single layer roofing sheet machine

T18 T35 Ibr Roofing Sheet Roll Forming Machine

T18 T35 Ibr Roofing Sheet Roll Forming Machine

Option B: Double-layer roofing sheet machine

Compare: When shall we choose a single layer, or when better by a double layer?

1. A single layer can do the production fast, but a double layer works only one layer each time.

2. Double layer takes up a small space and saves some cost compared with two sets of single-layer machines.

3. A single layer is easy to do the installation and maintain.

Advantages of Floor Deck Roll Forming Machine When it comes to modern construction projects, Floor

The ZTRFM heavy-duty coil recoiler is engineered for handling narrow-width and light-gauge strip materials, ensuring

The metal coil slitting and recoiling machine is designed for processing narrow-width strips with high

High-Precision Coil Embossing Machine for Decorative and Structural Metal Applications As a trusted coil embossing

STAY IN THE LOOP