The ZTRFM heavy-duty coil recoiler is engineered for handling narrow-width and light-gauge strip materials, ensuring efficient and precise rewinding in modern coil processing lines. Whether integrated with a metal slitting line or working alongside a cut-to-length system, this recoiler guarantees smooth operation, safe coil handling, and consistent coil quality.

Unlike traditional models, ZTRFM recoilers emphasize durability, adaptability, and user-friendly operation. They are widely applied across industries requiring stable rewinding of thin materials, including metal, plastics, textiles, and paper.

Key Functions of a Coil Recoiler

A recoiler serves as the terminal component of a processing line—its job is to re-form slit or processed materials into well-organized coils for storage, packaging, or further transportation.

Common applications include:

- Steel and aluminum coil processing

- Textile and fabric rewinding

- Plastic film and sheet production

- Paper and cardboard rolls

With an advanced design, the ZTRFM recoiler ensures distortion-free coil formation and prolongs the service life of materials.

heavy-duty coil recoiler

Technical Highlights

Featured Model – 50,000 lbs × 60″ Recoiler

| Item | Specification |

|---|---|

| Drum Diameter | 20″ with 24″ pads |

| Drum Face | 66″, hard chromed finish |

| Max Coil O.D. | 84″ |

| Capacity | 50,000 lbs (with outboard bearing); 40,000 lbs (without) |

| Passline Height | 48″ floor to drum center |

| Line Direction | Right-to-left configuration |

heavy-duty coil recoiler

Mechanical Features

- Powered Expansion Clamp – secures the coil tightly during winding

- Overarm Separator – precise strip alignment for neat coil formation

- Hydraulic Pushoff – effortless coil unloading

- Brake System – air-actuated brake for enhanced safety

- Bearing Support – reinforced outboard bearing for high load stability

Power System

- Main Motor: 150 HP DC, 850/2000 RPM, 500 V

- Gearbox: 3.5:1 ratio

- Speed Reducer: Dual-speed 5.41:1 & 10.8:1

Why Choose ZTRFM Coil Recoilers?

✔ Heavy-duty performance – supports up to 50,000 lbs with stability.

✔ Long-lasting drum – hard-chromed surface for extended service life.

✔ Accurate coil build-up – electronic controls ensure consistent winding.

✔ Multiple configurations – available in single-head, dual-head, or customized versions.

✔ Cost-efficient – reduces downtime and maintenance costs.

The ZTRFM coil recoiler is a versatile, robust, and cost-effective choice for businesses aiming to upgrade their coil handling efficiency. Its superior engineering and advanced features make it indispensable in slitting, rewinding, and cut-to-length operations.

heavy-duty coil recoiler

👉 For more details, customization options, or a quotation, contact our sales team today.

Stainless Steel & Aluminum Door Frame Making Machine The stainless steel and aluminum door frame

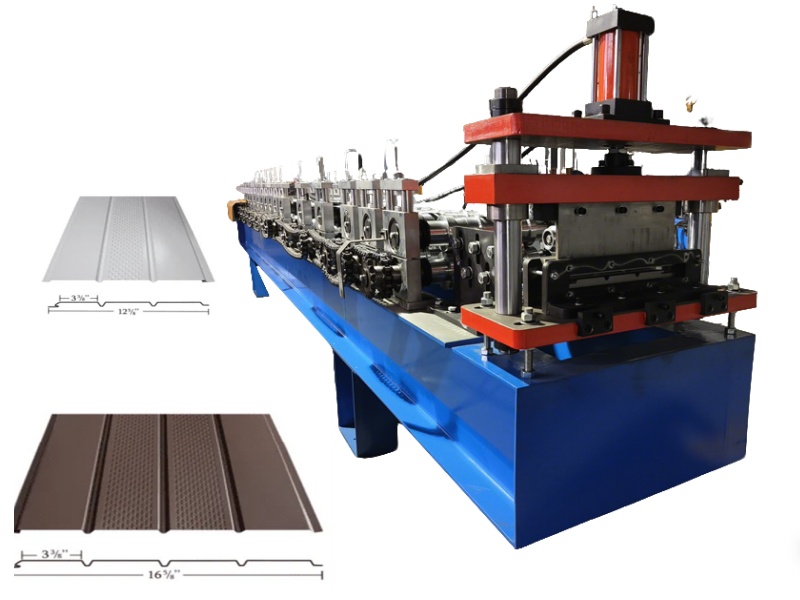

The ZTRFM Soffit Panel Roll Forming Machine is engineered for manufacturers who require fast, stable,

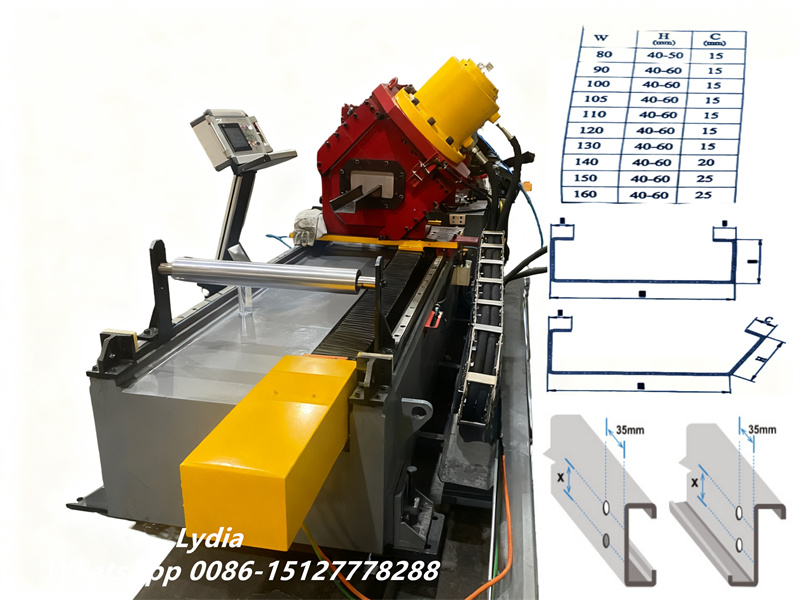

Cee & Zee Eave Struts Roll Forming Machine for Metal Buildings High-Performance Purlin Mill In

We are pleased to announce the successful delivery of our high-performance double-layer trapezoidal RIB metal

STAY IN THE LOOP