Stainless Steel & Aluminum Door Frame Making Machine

The stainless steel and aluminum door frame making machine is designed to produce strong, precise, and durable metal door frames for drywall and masonry construction.

Compared with traditional wooden frames, metal door frames offer higher strength, better fire resistance, and longer service life. Therefore, more contractors and developers now prefer steel and aluminum door frames in modern buildings.

steel door frame roll forming machine

To meet this growing demand, Reliance has developed a professional door frame roll forming machine that combines embossing, punching, and cutting in one automated production line.

Suitable Raw Materials & Processing Capability

First of all, this steel door frame roll forming machine supports multiple materials and thickness ranges, which makes it suitable for different markets and standards.

- Stainless steel thickness: 1.0 – 2.0 mm

- Aluminum thickness: 1.0 – 2.0 mm

In addition, the machine integrates embossing flower patterns and hydraulic punching for lock holes and notches.

As a result, manufacturers can produce both decorative and functional door frames efficiently.

door frame forming machine

Door Frame Roll Forming Machine Workflow

To ensure stable production and cost control, the line adopts a stop punching and stop cutting system.

Meanwhile, the forming process remains smooth and accurate.

aluminum door frame roll forming machine

Production flow:

Uncoiler → Powered Leveling → Inline Hydraulic Pre-Punching → Roll Forming → Hydraulic Post Cutting (Flying Shear)

Main Technical Parameters

| Item | Specification |

|---|---|

| Machine Name | Stainless Steel & Aluminum Door Frame Making Machine |

| Formed Material | Stainless Steel / Aluminum |

| Material Thickness | 1 – 2 mm |

| Roller Stations | 18 stations (customizable) |

| Shaft Diameter | 70 mm solid shaft |

| Roller Material | Cr12 |

| Frame Structure | 400H-beam welded steel |

| Drive System | Chain transmission |

| Forming Speed | 5 m/min (adjustable) |

| Main Motor Power | 15 kW |

| Hydraulic Power | 5.5 kW |

| Cutting Type | Hydraulic post cutting |

| Blade Material | Cr12Mov |

| Control System | PLC automatic control |

| Voltage | 380V / 50Hz / 3 Phase (customized) |

| Machine Weight | Approx. 8 tons |

| Machine Size | 8500 × 800 × 1200 mm (customized) |

metal door frame production line

Key Machine Components & Functions

Feeding and Leveling Device

Firstly, the feeding device adjusts the coil width precisely and protects the surface material.

At the same time, the leveling unit ensures smooth and flat feeding before forming.

stainless steel door frame making machine

Embossing Flower Device

Moreover, the embossing unit allows customized flower patterns.

This process not only improves the door frame appearance but also increases overall strength.

Hydraulic Pre-Punching System

In addition, the hydraulic punching system integrates directly into the line:

- 3 punching stations for holes

- 1 punching station for notches

- Hydraulic power: 11 kW

As a result, the machine completes punching without stopping the entire production flow.

stainless steel door frame making machine

stainless steel door frame making machine

Main Roll Forming Machine

The main forming unit uses heat-treated 45# steel shafts and chrome-coated rollers, ensuring long service life and stable performance.

Meanwhile, the gear and chain transmission guarantees accurate forming at adjustable speeds from 5–10 m/min.

PLC Control Cabinet

Furthermore, the PLC control system adopts Siemens electronic components and a touch-screen interface.

Operators can easily set length, quantity, and batch production, while multi-language support simplifies overseas operation.

Hydraulic Station & Receiving Table

Finally, the low-noise hydraulic station includes a cooling fan and real-time temperature monitoring.

The receiving table collects finished door frames safely and efficiently.

Advantages of Our Door Frame Making Machine

- Suitable for stainless steel and aluminum door frame production

- Integrated embossing, punching, and cutting

- Stable structure with long service life

- Easy operation and low maintenance cost

- Ideal for mass production and export projects

-

aluminum door frame roll forming machine

Application Fields

- Drywall metal door frames

- Masonry steel door frames

- Residential and commercial buildings

- Industrial and public construction projects

steel door frame roll forming machine

metal door frame production line

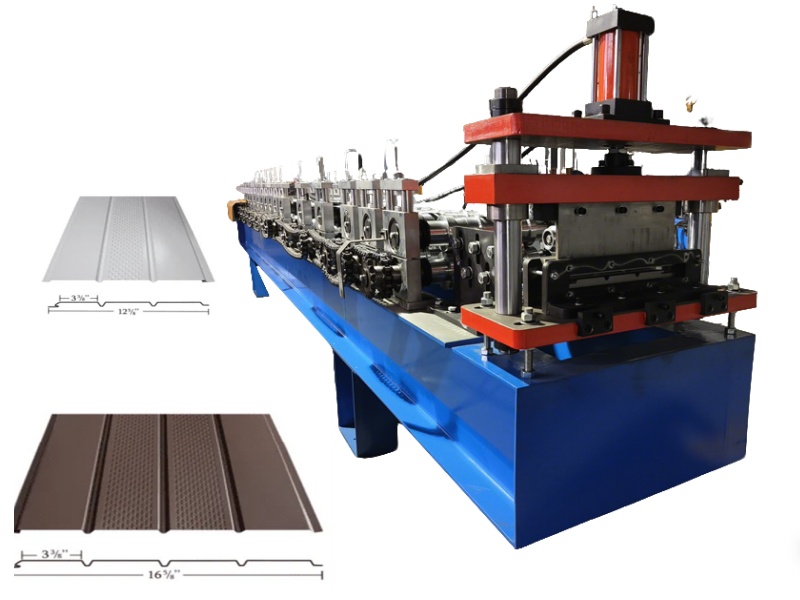

The ZTRFM Soffit Panel Roll Forming Machine is engineered for manufacturers who require fast, stable,

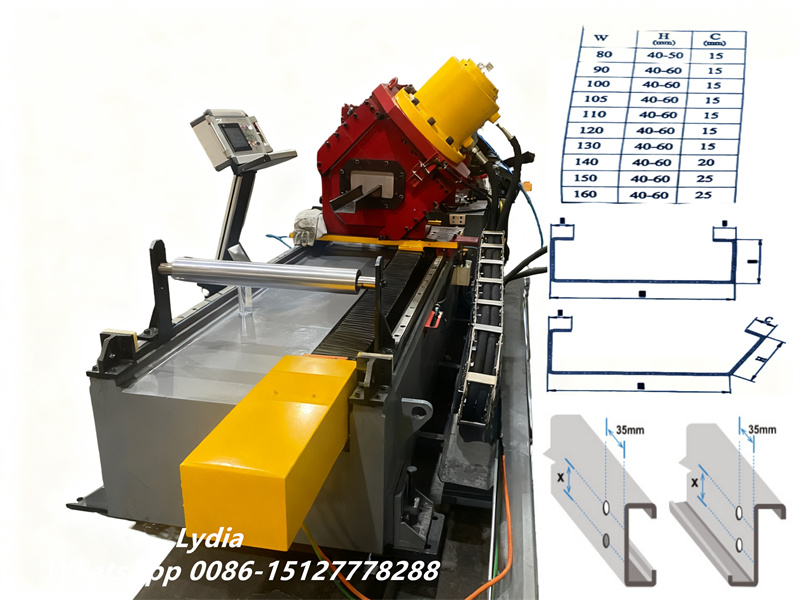

Cee & Zee Eave Struts Roll Forming Machine for Metal Buildings High-Performance Purlin Mill In

We are pleased to announce the successful delivery of our high-performance double-layer trapezoidal RIB metal

DIN Rail Roll Forming Machine Automatic DIN Rail Channel Making Line What is DIN Rail?

STAY IN THE LOOP