The ZTRFM Soffit Panel Roll Forming Machine is engineered for manufacturers who require fast, stable, and high-precision production of aluminum and PPGI soffit panels. Designed for both medium-volume and high-volume operations, this production line combines advanced automation, durable tooling, and multiple ventilation options to meet the growing demand for architectural soffit systems.

Whether your project requires solid panels, center-vented panels, or fully vented soffit, the ZTRFM system delivers industry-leading performance with customizable configurations.

Upgrade to a professional soffit panel production line that guarantees quality, consistency, and long-term value.

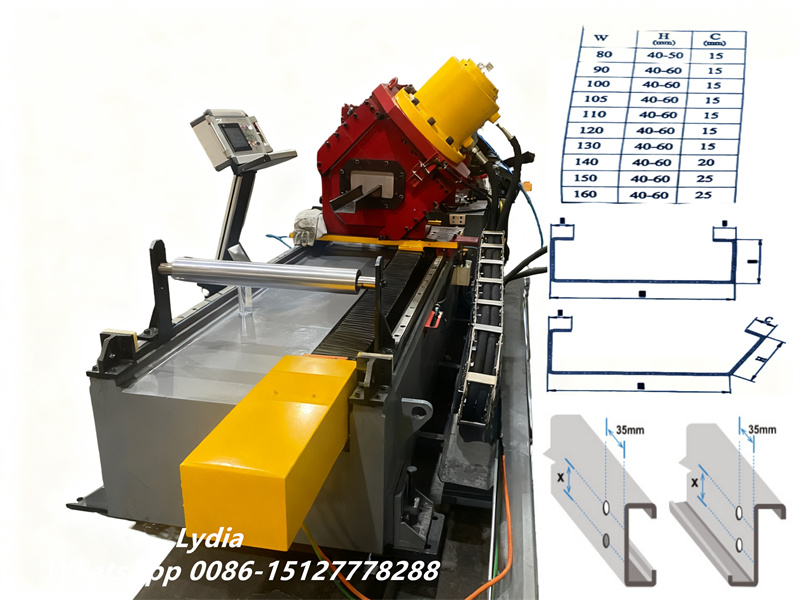

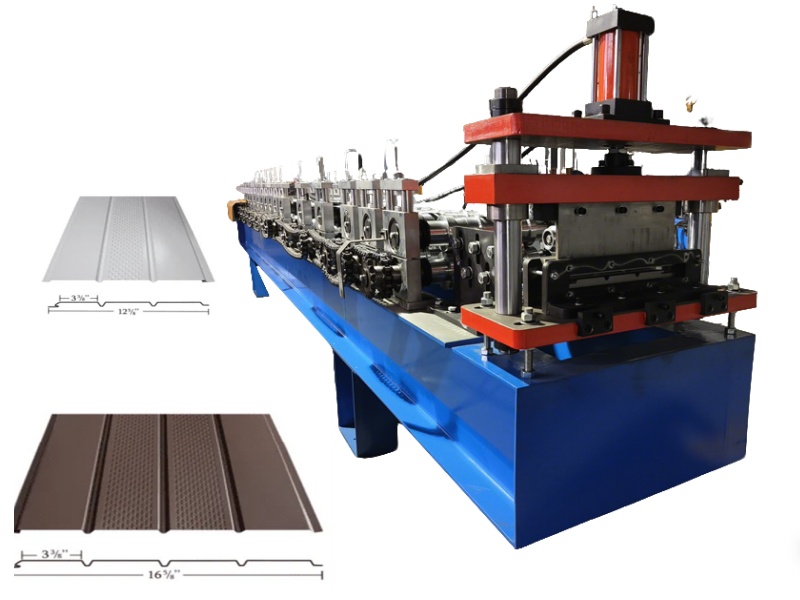

soffit panel roll forming machine

Standard Features of Soffit Panel Roll Forming Machine

- Hydraulic drive system with front scissor shear for smooth and reliable cutting.

- 3 HP electric-hydraulic power unit, compatible with 220V single-phase operation.

- Adjustable panel width from 10″ to 24″ to meet diverse design specifications.

- High production speed up to 30 m/min for efficient output.

- Suitable for 24-gauge steel and 12-16 oz copper, offering excellent material flexibility.

ZTRFM provides both feed-to-stop and high-speed flying post-cut system options, allowing you to customize your line based on production goals.

vented soffit production line

With our specialized lancing pass, you can produce:

- Flat soffit panels

- Center-vented panels

- Fully vented panels

This versatility enables manufacturers to satisfy a wide range of customer requirements.

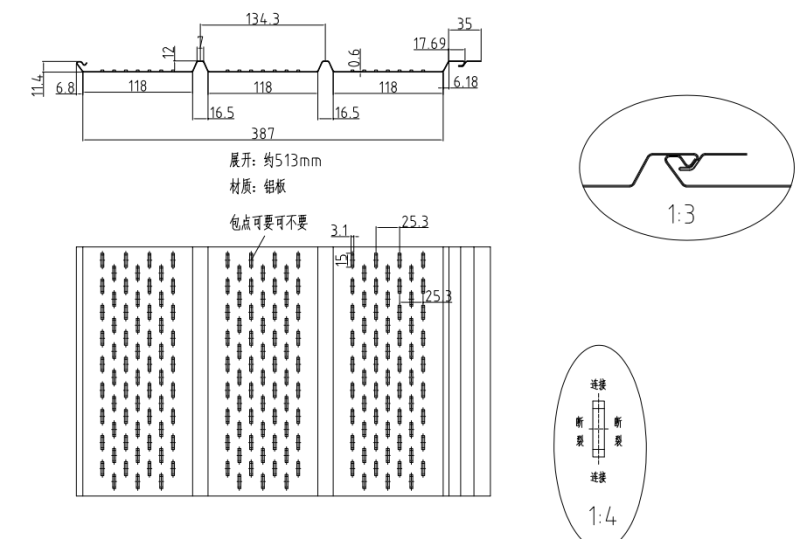

Triple-4 Vented Soffit Panel Option

ZTRFM offers specialized tooling for Triple-4 soffit, a 12″ wide panel designed to fit 3/8″ channel.

Available in:

- Solid profile

- Center-vented profile

The vented model provides 3.24 square inches of free airflow per linear foot, allowing excellent attic ventilation and moisture control.

Profile Drawing:

soffit panel roll forming machine

soffit panel roll forming machine

Why Soffit Panels Matter

Soffit is essential for protecting a building’s roof structure and improving its appearance. It:

- Covers and conceals exposed rafter beams

- Enhances the roofline with clean, finished aesthetics

- Shields wooden rafters from weather, preventing moisture damage

hydraulic fly cutting soffit machine

Benefits of Vented Soffit

- Improves attic airflow

- Reduces moisture accumulation

- Enhances overall energy efficiency

ZTRFM soffit panel lines ensure your final product meets both functional and architectural requirements.

ROLLFORMER Features

- Precision entry guide with optional hand-wheel adjustment

- Sturdy cast rollformer stands and bearing blocks for long-term durability

- Micrometer dials for accurate alignment

- Precision-ground shafts for consistent forming quality

- AC positioning motor for accurate and smooth operation

- Chain-drive or gearbox-drive systems available

- OSHA-compliant safety guarding for enhanced operator protection

These features ensure stable, high-quality production even under continuous operation.

ROLLER TOOLING Specifications

- All roller tooling is designed and manufactured in-house for quality control

- Optimized using proprietary computerized tooling design technology

- Built from #45 steel with hard chrome coating, or D2 steel for enhanced durability

- Steel tooling spacers eliminate the need for set collars

- Optional split-spacer system for fast changeover: supports 3-rib / 4-rib soffit profiles

high-speed roll forming

Technical Specifications

| No. | Item | Specifications |

|---|---|---|

| 1 | Raw Material | Aluminum, PPGI |

| 2 | Material Thickness | 0.3–0.5 mm (22–26 gauge) |

| 3 | Decoiler | 5T hydraulic decoiler (other capacities optional) |

| 4 | Roller Stations | 22 stations |

| 5 | Roller Material | 45# steel with quenched treatment |

| 6 | Shaft Diameter | 70 mm |

| 7 | Work Speed | 0–30 m/min |

| 8 | Transmission | Single chain drive |

| 9 | Motor Power | 7.5 kW |

| 10 | Machine Frame | 350# H-beam welded frame |

| 11 | Cutting Type | Hydraulic flying cutting |

| 12 | Hydraulic Power | 5.5 kW |

| 13 | Cutting Blade | CR12 steel |

| 14 | Hydraulic Motor Power | 5.5 kW |

| 15 | Control System | PLC (Delta / Siemens / Mitsubishi) |

| 16 | Touch Screen | Delta / Siemens / Mitsubishi |

| 17 | Encoder | Omron |

The ZTRFM Soffit Panel Roll Forming Machine offers unmatched reliability, precision, and versatility for modern soffit manufacturing. With high-speed production, flexible ventilation options, durable tooling, and fully customizable configurations, this production line is the ideal choice for manufacturers seeking long-term value and superior output quality.

Upgrade your facility with an advanced soffit panel line — and experience the ZTRFM difference.

Stainless Steel & Aluminum Door Frame Making Machine The stainless steel and aluminum door frame

Cee & Zee Eave Struts Roll Forming Machine for Metal Buildings High-Performance Purlin Mill In

We are pleased to announce the successful delivery of our high-performance double-layer trapezoidal RIB metal

DIN Rail Roll Forming Machine Automatic DIN Rail Channel Making Line What is DIN Rail?

STAY IN THE LOOP