The metal coil slitting and recoiling machine is designed for processing narrow-width strips with high accuracy and efficiency. It is widely used in industries such as electronics, automotive, and precision sheet metal fabrication. This equipment is capable of slitting metal coils into specified widths and rewinding them under controlled tension. With advanced design, precise machining, and reliable electrical control, it ensures stable operation and premium slitting performance.

Slitting Machine

I、Overview

This equipment is designed for slitting metal coil strips into specified widths, and then rewinding them into coils under controlled recoiling tension.

Structural Description:

The slitting machine is composed of a guiding device, main body, power unit, and scrap edge coiling device.

Pre-shearing guiding: A pair of guide bars is used to redirect the strip material into the guiding system. The guiding system consists of quenched steel rollers made of 45# steel, quenched to HRC40–45. The position of the guide bars can be manually adjusted to suit different strip widths.

Main body: Both the fixed and movable housings are made of castings to ensure the accuracy and stability of dimensions. The sliding grooves and sliders of the housings are precisely fitted to guarantee the parallelism of the upper and lower knife shafts during vertical movement.

Knife shaft assembly: Composed of knife shaft, pressure sleeve, and locking nut. The assembly adopts a combined structure, allowing installation of both slitting knives with spacers and fixed knives. It is also equipped with a stripper bar device, enabling convenient strip removal. The rubber ring stripper has no relative motion with the moving strip, effectively preventing secondary scratches and abrasions on the strip surface.

Knife shaft: Made of GCr15 material, processed through forging, tempering (HB220–240), and surface quenching (HRC40–45), followed by chrome plating and polishing.

Power unit: Consists of motor, reducer, chain drive, clutch, and base.

Motor: Controlled by variable frequency drive for speed regulation.

Reducer: Gear reducer with chain transmission, delivering the required cutting speed and torque to the knife shaft for slitting.

Base: Entire frame is made of castings to prevent deformation and ensure overall precision of the equipment.

Scrap edge coiling device: Uses a single-head recoiling method to wind two scrap edges simultaneously. It is equipped with a 5kg magnetic powder tension device, with torque adjustable via magnetic powder. The recoiling head consists of four steel bars that can expand radially on one side to form a taper. It is fitted with side plates and a handwheel expansion mechanism to facilitate scrap roll unloading.

Slitting Machine

II、Technical Parameters

| No. | Item | Parameter |

| 1 | Material | Metal strip coil |

| 2 | Coil thickness | 0.1mm–0.5mm |

| 3 | Coil width | ≤200mm |

| 4 | Max. coil outside diameter | Φ1000mm |

| 5 | Coil inner diameter | Φ508mm |

| 6 | Max. coil weight | 500kg |

| 7 | No. of strips | ≤10 strips |

| 8 | Slitting accuracy | ±0.02mm |

| 9 | Slitting speed | 0–80 m/min |

| 10 | Finished coil inner dia. | Φ76mm (with optional collecting tray) |

| 11 | Finished coil max O.D. | Φ500mm |

| 12 | Slitter motor power | 5.5kW |

| 13 | Recoiler motor power | 5.5kW |

| 14 | Total capacity | 11kW |

| 15 | Total weight | 2.5T |

| 16 | Running direction | Right to left (when facing the operation table) |

| 17 | Recoiling method | Double-recoiling, longitudinal |

III、Equipment Composition

- Decoiler – 1 set

- Slitter – 1 set (with scrap winder and recoiler)

- Electrical control system – 1 set

- User manual & accessories – 1 set

IV、 Equipment Description

Slitting Machine

4.1 Decoiler

Passive decoiler, consisting of base and expanding mandrel.

Manual expanding mandrel: Φ480–Φ520mm

Equipped with a 5kg magnetic powder tension device to prevent coil loosening.

4.2 Disc Slitter

Function: To slit strip material into required finished widths.

Structure & Features:

Includes fixed frame, movable frame, knife shaft assembly.

Movable frame slides on linear guide rails, convenient for tool change.

Slitting Machine

| Item | Parameter |

| Base & frame structure | Integral casting |

| Speed | 0–80 m/min |

| Knife shaft size | Φ60mm × 320mm (with mechanical locknut) |

| Spacer ring size | Φ130 × Φ60 × 3mm |

| Cutter size | Φ85 × Φ60 × B mm (B = thickness) |

| Main motor power | AC 5.5kW |

| Knife shaft bearings | NTN (Japan) |

| Slitting capacity | ≤10 strips (at 0.5mm thickness) |

| End face runout | ≤0.003mm |

| Radial runout | ≤0.005mm |

| Guide rail | HIWIN |

Knife shafts are integral type for high precision.

Motor-driven lifting system adjusts upper knife shaft vertically; manual fine adjustment for cutting depth.

4.3 Recoiler

| Item | Parameter |

| Structure | Integral casting frame, single cantilever |

| Recoiling type | Upper recoiling |

| Quantity | 1 set |

| Capacity | ≤500kg |

| Shaft diameter | Φ76mm solid shaft (with optional tray) |

| Max coil O.D. | Φ500mm |

| Power | 5.5kW |

4.4 Electrical Control System

This system adopts variable frequency speed regulation to drive both the slitting motor and the recoiling motor for adjustable operation.

During production line operation, the overall line speed is manually set by a potentiometer and can be stopped at any time by pressing the stop button, bringing the entire line to a halt.

The electrical control system consists of a single control console.

The unit operates on AC power supply.

Composition and Functions:

The system is equipped with an operation console and one electrical control cabinet. The entire line adopts centralized control. The main operation console features digital display, high/low speed adjustment, manual feeding, continuous slitting, and fault alarm functions. Other electrical control components are imported products or joint-venture products of the same grade.

Main Electrical Brands:

| No. | Component | Brand | Remarks |

| 1 | Inverter | Siemens | |

| 2 | Magnetic powder brake | Dongguan Yanxin | |

| 3 | Optical rod traverser | Zhejiang Keyi | |

| 4 | Push button | Schneider | |

| 5 | Reducer | Jiangsu Julin | |

| 6 | Frequency motor | Jiangsu Julin |

The ZTRFM heavy-duty coil recoiler is engineered for handling narrow-width and light-gauge strip materials, ensuring

High-Precision Coil Embossing Machine for Decorative and Structural Metal Applications As a trusted coil embossing

Ridge cap Roll Former-12” universal Ridge cap Ridge Cap Roll Former – Hems both

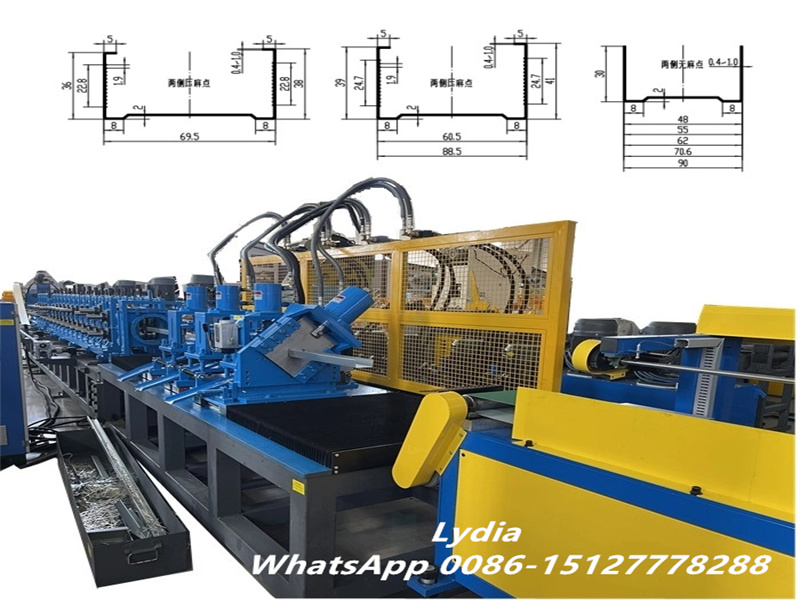

Drywall Stud and Track Roll Forming Machine High-Speed Light Steel Keel Production Line Our Drywall

STAY IN THE LOOP