1/4″Wall Panel Machines of Specifications

Wall panels serve as decorative coverings for various types of buildings, including industrial and administrative facilities, shopping centers, sports complexes, markets, and office spaces. These panels enhance a building’s appearance while providing protection against various atmospheric conditions.

Wall panels offer several notable benefits:

The roof and wall panel roll forming machines are ergonomic, highly durable, and feature concealed fastenings. They can be installed vertically on walls, horizontally on false ceilings, or at any inclined angle, including the cladding of cylindrical surfaces. Additionally, they are lightweight and easy to install.

Metal siding panels, known for their long lifespan and appealing look, are available in lengths ranging from 0.5 to 6 meters and thicknesses between 0.5 to 1.2 mm. They are manufactured through roll-forming from light-gauge galvanized steel with a polymer coating, such as polyester or plastisol. For convenient installation, these siding panels come with pre-cut slots for fastenings and lock-on connections.

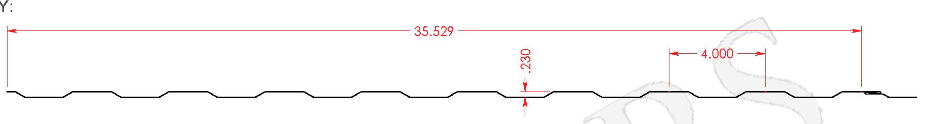

Profile drawing:

Standard Features:

- Polyurethane Drive Rollers

- Roller System with Shear Dies

- Hydraulic Drive & Shear

- Powder-Coated Frame

- Can form 8”, 12”, and 16” WAV-style profiles with either fastener flange or clip-style attachment

- UNIQ Automatic Control System

- Hydraulic Shear

- Hydraulic Drive

- Equipped with 16 HP Gas Engine and/ or 460V 3-Phase Electric Power

- Minimum Flat Sheet Feed – Length is 62 Inches (1,575mm)

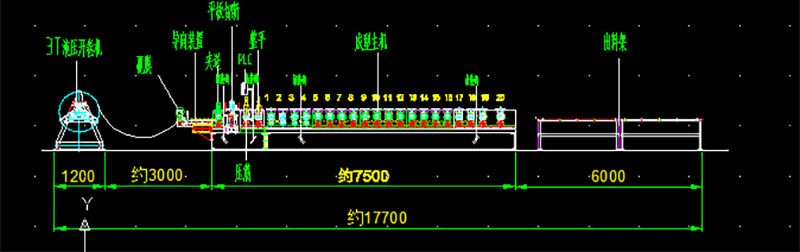

The technical specifications of the metal roof wall panel roll forming machine :

| NO | Name | Specifications |

| 1 | Raw material | Galvanized steel and Pre-painted steel |

| 2 | Raw material thickness | 0.3-0.8mm |

| 3 | Decoiler | 5T Hydraulic decoiler(Different capacity for option,manual one for option) |

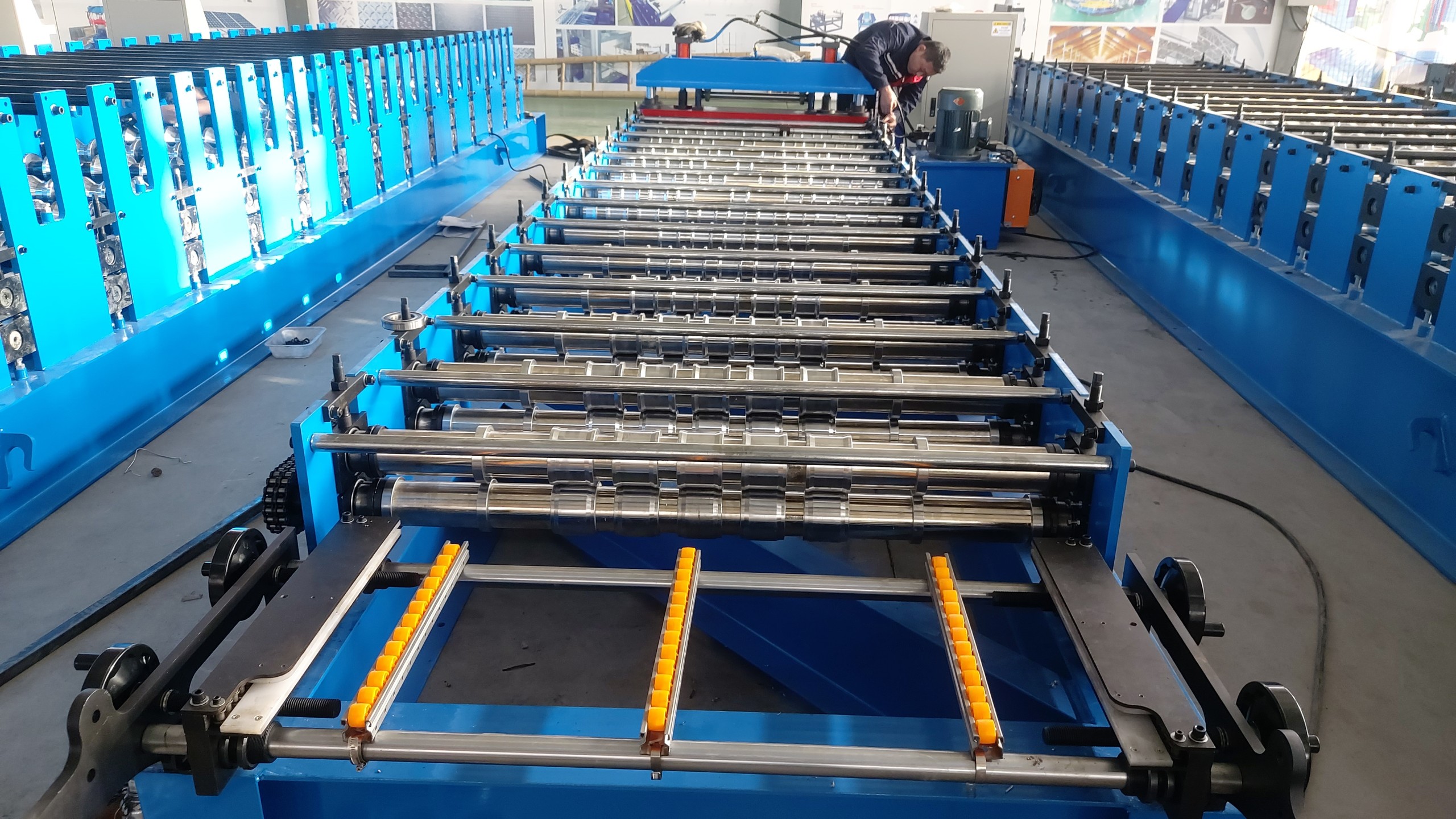

| 4 | Roller station | 18 stations |

| 5 | Roller material | 45# steel with quenched treatment |

| 6 | Shaft diameter | 80mm |

| 7 | Shaft material | 45# steel with tempered |

| 8 | Transmission | by gear box transmission |

| 9 | Motor power | 5.5kw motor |

| 10 | Machine frame | 400H steel welded |

| 11 | Cutting type | Hydraulic cutting |

| 12 | Hydraulic power | 5.5kw |

| 14 | Cutting blade material | Cr 12 High Grade Steel |

| 15 | Cutting tolerance | +/-1mm |

| 16 | Control system | PLC |

| 17 | Brand | PLC:Delta/Siemens/Mitsubishi

Touch screen:Delta/Siemens/Mitsubishi Encoder:Omron |

Advantages of Floor Deck Roll Forming Machine When it comes to modern construction projects, Floor

Full-Automatic T18/T35 IBR Roofing Sheet Roll Forming System with Dual-Layer Capability This advanced roll forming

The ZTRFM heavy-duty coil recoiler is engineered for handling narrow-width and light-gauge strip materials, ensuring

The metal coil slitting and recoiling machine is designed for processing narrow-width strips with high

STAY IN THE LOOP