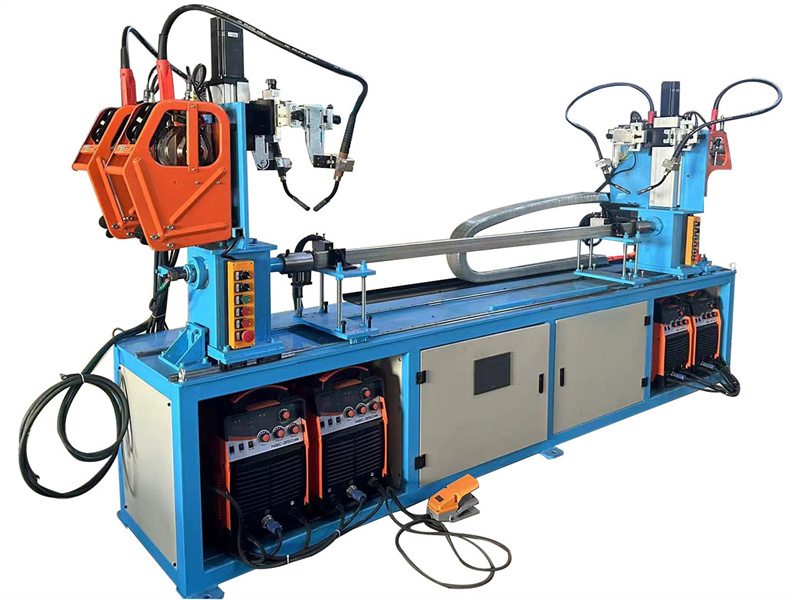

Downspout Water Gutter Pipe Making Roll Forming Machine

An efficient rainwater drainage system starts with precision manufacturing.

Our Downspout Water Gutter Pipe Making Roll Forming Machine is designed to produce high-quality metal downspouts with stable performance, clean cutting, and long-term reliability. It is an ideal solution for manufacturers serving residential, commercial, and industrial construction markets.

By combining advanced roll forming technology with a proprietary cutting system, this machine delivers consistent output, reduced material waste, and a safer working environment.

downspout roll forming machine with exit shear cutting system

Multiple Pipe Shapes for Different Markets

In addition, the machine is capable of forming and cutting various downspout profiles, such as:

- Rectangular downspouts (2”×3”, 3”×4”)

- Square pipes

- Round pipes

- Corrugated pipes

This flexibility allows manufacturers to easily meet different architectural styles and regional standards without frequent equipment changes.

Profile Drawing:

Clean and Precise Cutting Technology

Unlike traditional saw cutting, this machine is equipped with ZTRFM’s proprietary exit shear.

Thanks to its pneumatic drive and cam-controlled blade movement, the shear cuts the downspout smoothly around the profile without squeezing corners or creating deformation. Consequently:

- Cuts are straight, burr-free, and clean

- No flying chips or metal debris are produced

- Electrical components and rollers remain protected

- Post-processing work is greatly reduced

In comparison, saw cutting often generates chips that contaminate switches and rollers. Therefore, the exit shear offers a cleaner workspace and more reliable long-term operation.

automatic rainspout roll forming machine PLC control

High Versatility for Materials and Applications

Moreover, this downspout roll forming machine supports a wide range of materials, including:

- Aluminum (as thin as 0.017″)

- Galvanized steel

- Color-coated steel

- 22-gauge steel

Whether you are producing aluminum downspouts or steel elbow blanks, the exit shear remains the only practical solution for short-piece production directly from the machine.

water gutter pipe making machine for aluminum and steel

Enhanced Safety and Low-Noise Operation

Compared with traditional saw-based cutting systems, the exit shear operates with significantly lower noise levels.

Furthermore, its fully enclosed structure prevents direct contact with the blade, effectively reducing the risk of operator injury and improving overall workplace safety.

Durable Structure and Long Service Life

To ensure durability, the machine frame is manufactured from 350H steel, while the rollers are made of 45# steel with hard chrome plating.

In addition, all visible surfaces feature a powder-coated finish, which provides excellent resistance to scratching, fading, and corrosion—maintaining both performance and appearance over time.

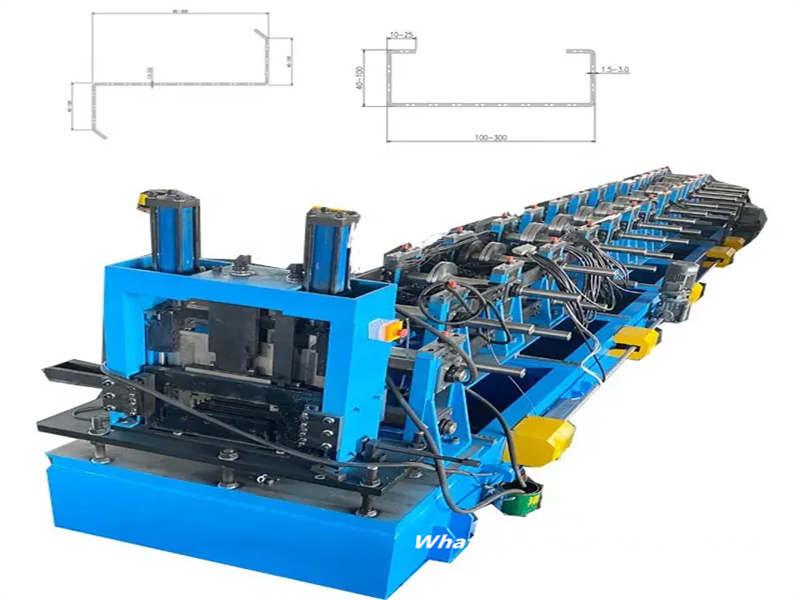

Technical Specifications of the Downspout Roll Forming Machine

| Item | Specification |

|---|---|

| Formed Material | PPGI, GI, Aluminum, GL |

| Material Thickness | 0.4 – 0.8 mm |

| Downspout Sizes | 2”×3”, 3”×4” |

| Decoiler | Hydraulic automatic (manual decoiler free) |

| Roller Stations | 19 rows with vertical rollers |

| Shaft Diameter | 70 mm solid shaft |

| Roller Material | 45# steel, hard chrome plated |

| Machine Frame | 350H steel |

| Drive System | Chain transmission |

| Cutting System | Automatic hydraulic cutter, Cr12Mov |

| Forming Speed | 10–15 m/min (adjustable, cutting excluded) |

| Main Motor Power | 7.5 kW |

| Hydraulic Power | 4 kW |

| Control System | PLC automatic control, multi-language support |

| Voltage | 380V / 50Hz / 3Phase (customizable) |

| Machine Size | 11000 × 900 × 1100 mm (customizable) |

| Machine Weight | Approx. 4.5 tons |

square downspout roll forming machine production line

Wide Range of Applications

This downspout roll forming machine is widely used for manufacturing:

- Rainwater downpipes for residential buildings

- Water gutters for commercial facilities

- Rainspouts for industrial structures

- Square and round rain pipes for modern architecture

- Customized gutter profiles for different countries

Additionally, an optional downspout elbow machine can be integrated to complete the full rainwater drainage system production line, enabling smooth direction changes and higher product value.

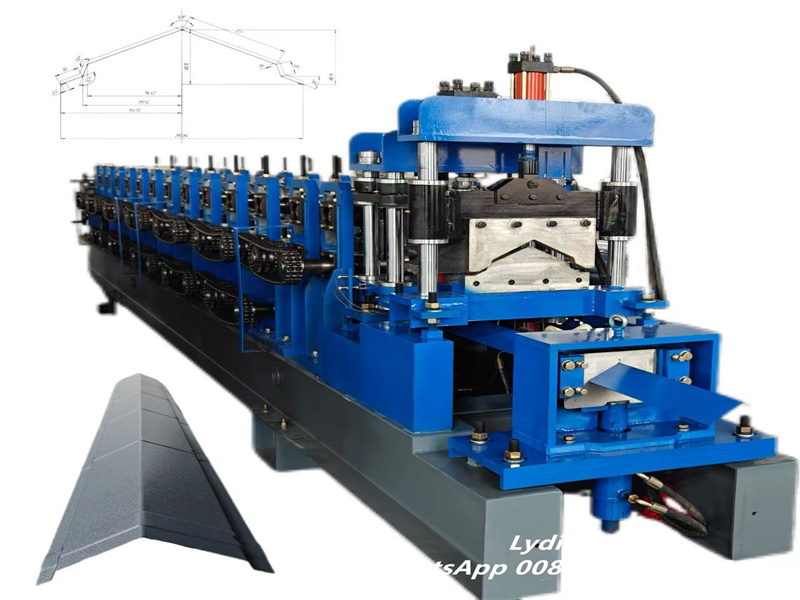

Rectangle Downspout:

Round Downspout:

Downspout Water Gutter Pipe Making Roll Forming Machine Working Flow:

The Technical Specifications Of Metal Downspout Pipe Roll Forming Machine :

| Metal Downspout Pipe Roll Forming Machine | ||

| 1.Formed Material | PPGI,GI,AI,GL | Thickness:0.4-0.8mm

Downspout size:2”*3”,3”*4” |

| 2.Decoiler | Hydraulic automatic decoiler | Manual decoiler(will give you as free) |

| 3.Main body | Roller station | 19 rows with a series of vertical rollers |

| Diameter of shaft | 70mm solid shaft | |

| Material of rollers | 45# steel, hard chrome plated on the surface | |

| Machine body frame | 350 H steel | |

| Drive | Chain transmission | |

| Dimension(L*W*H) | 11000*900*1100(customize) | |

| Weight | 4.5T | |

| 4.Cutter | Automatic | cr12mov material, no scratches, no deformation |

| 5.Power | Motor Power | 7.5 KW |

| Hydraulic system power | 4 KW | |

| 6.Voltage | 380V 50Hz 3Phase | As your requirement |

| 7.Control system | Electric Box | Customized(famous brand) |

| Language | English(Support multiple languages) | |

| PLC | Automatic production of the whole machine. Can set batch, length, quantity, etc. | |

| 18.Forming Speed | 10-15m/min (not including cutting) | The speed is adjustable |

In summary, the Downspout Water Gutter Pipe Making Roll Forming Machine combines precision forming, clean cutting, operational safety, and long-term durability.

With its advanced exit shear technology, flexible material compatibility, and robust structure, it is an excellent investment for manufacturers seeking efficient production, consistent quality, and strong market competitiveness.

automatic rainspout roll forming machine PLC control

More detailed pictures of the machine:

Working Flow of the Downspout Roll Forming Machine

- Metal coil loading on decoiler

- Material feeding and leveling

- Progressive roll forming

- Profile shaping and calibration

- Automatic exit shear cutting

- Finished downspout output

Each step is automatically controlled by the PLC system, ensuring accurate length, quantity, and batch production.

Double-Sided CO₂ / MIG Welding Machine The 2026 New High-Precision Seam-Welded Square & Rectangular Tube

Professional C & Z Purlin Roll Forming Machine Heavy-Duty Automatic Machine for Structural Steel Production

Round Downpipe Roll Forming Machine & Aluminum Gutter Guard Production Line Efficient rainwater drainage is

Double-Layer Ridge Capping Roll Forming Machine In modern roofing construction, ridge caps play a critical

STAY IN THE LOOP