Round Downpipe Roll Forming Machine & Aluminum Gutter Guard Production Line

Efficient rainwater drainage is a critical part of modern roofing systems. To meet growing market demand for durable, attractive, and cost-effective drainage components, our Round Downpipe Roll Forming Machine and Aluminum Gutter Guard Making Machine offer a complete, automated manufacturing solution.

Rollers and shafts of round downspout forming machine with chrome plating

These machines are designed for high-volume production while maintaining excellent forming accuracy, smooth surface quality, and long-term operational stability.

Round Downpipe Roll Forming Machine Overview

The round downpipe roll forming machine—also referred to as a round downspout forming machine—is engineered to manufacture circular downpipes with high precision and efficiency. These pipes guide rainwater from roof gutters down to ground-level drainage systems, effectively protecting building facades, foundations, and surrounding landscapes from water damage.

Round downspout drainage system for residential and commercial buildings

Unlike traditional welded pipe production, this machine adopts a mechanical interlock forming system. The edges of the metal strip are locked together during roll forming, eliminating the need for welding. This design not only improves appearance and strength but also significantly reduces energy consumption, labor costs, and post-processing requirements.

What Is a Round Downspout?

A round downspout is a vertical drainage pipe installed along the exterior wall of a building. It connects directly to the gutter outlet at the roof edge and safely channels rainwater downward into drains or designated runoff areas.

With increasing emphasis on both aesthetics and durability in construction projects, round downspouts have become a preferred choice in residential, commercial, and industrial buildings worldwide. As a result, reliable downpipe roll forming equipment is now essential for roofing material manufacturers.

Round downspout drainage system for residential and commercial buildings

Profile Design & Forming Advantages

The downpipe profile features a tight interlocking seam, formed entirely through mechanical pressure. This ensures:

- Strong seam connection without welding

- Smooth, uniform pipe appearance

- Consistent diameter and wall thickness

- Reduced machine complexity and maintenance

Thanks to this intelligent profile design, the machine is ideal for long-term, continuous industrial production.

Technical Specifications – Round Downpipe Roll Forming Machine

| Item | Specification |

|---|---|

| Working Speed | 8–10 m/min |

| Roller Stations | 22 stations |

| Roller Material | 45# forged steel, hard chrome plated |

| Shaft Diameter | 70 mm, heat-treated |

| Bearings | Harbin brand |

| Machine Frame | 20 mm thick steel wall plate |

| Transmission System | Chain drive |

| Main Motor | 7.5 kW (Siemens) |

| Hydraulic Station | 7.5 kW (with cooling fan) |

| Hydraulic Pressure | 12 MPa |

| PLC System | Delta |

| Encoder | Omron |

| Electrical Components | Schneider |

| Cutting Method | Hydraulic cutting, Cr12MoV (quenched) |

| Cutting Tolerance | ±2 mm |

| Raw Materials | PPGI, PPGL, GI, GL |

| Material Thickness | 0.4–0.6 mm |

| Decoiler Type | Passive |

| Decoiler Capacity | 3 tons |

| Coil Inner Diameter | 470–530 mm adjustable |

The PLC control system allows operators to easily set pipe length, production quantity, running speed, and other parameters, ensuring stable and automated operation with minimal manual intervention.

Why Choose Our Round Downpipe Forming Machine?

- Produces smooth, dimensionally accurate round downspouts

- Interlock forming eliminates welding processes

- Low labor and operating costs

- Precise hydraulic cutting with excellent repeatability

- Compatible with multiple coated steel materials

By investing in this machine, manufacturers can significantly improve productivity while delivering high-quality drainage products to the market.

Gutter Guard Roll Forming Machine Complete Gutter Protection Machine

In addition to downpipes, effective gutter protection is essential for modern rainwater systems. Gutter guards, also known as gutter covers, prevent leaves, debris, and dirt from entering gutters, ensuring uninterrupted water flow.

Without proper protection, clogged gutters can lead to overflow, structural damage, and frequent maintenance. Installing gutter guards greatly extends gutter lifespan and reduces cleaning frequency.

Aluminum gutter guard roll forming machine production line

Aluminum Perforated Gutter Guard Machine Line

Our aluminum perforated gutter guard production line is designed to manufacture high-quality gutter protection panels from flat aluminum sheets. The finished products allow rainwater to pass through freely while blocking leaves and debris.

This complete line includes:

- Yangli 16-ton mechanical punch press

- Custom precision perforation molds

- Continuous roll forming system

Depending on customer requirements, the machine can produce flat or wave-shaped panels with round holes, slots, or louvered perforations.

Market Applications & Performance

In regions with heavy snowfall, seasonal rainfall, or dense vegetation—such as Russia and other cold-climate markets—roof drainage systems must withstand harsh environmental conditions. Round downspouts and aluminum gutter guards are widely used in both residential and industrial buildings due to their durability and visual appeal.

The strong interlock seams of the round downpipe and the corrosion-resistant aluminum gutter guards ensure long-term reliability, even under extreme weather conditions.

Applications of Gutter Guard Covers

- Residential housing projects

- Commercial and industrial buildings

- Areas with heavy leaf accumulation

As a result, property owners and contractors can significantly reduce maintenance costs while improving overall drainage performance.

Round downspout drainage system for residential and commercial buildings

Complete Rainwater System Manufacturing Solution

Together, the round downpipe roll forming machine and gutter guard roll forming machine provide a comprehensive solution for modern rainwater drainage systems. With automated production, precise forming, and robust machine construction, manufacturers can efficiently meet global roofing market demands and remain competitive.

If you require custom pipe diameters, special profiles, or integrated gutter system solutions, this production line can be fully customized to match your specific project needs.

Downspout Water Gutter Pipe Making Roll Forming Machine An efficient rainwater drainage system starts with

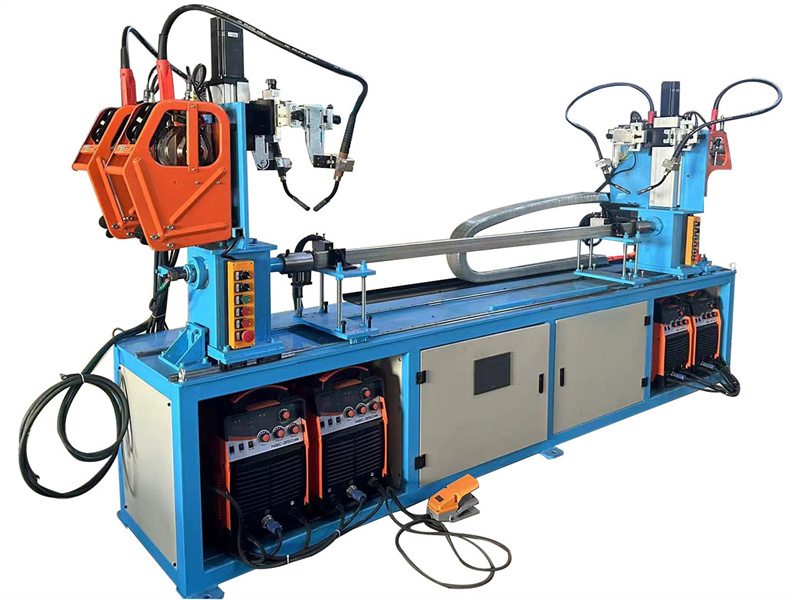

Double-Sided CO₂ / MIG Welding Machine The 2026 New High-Precision Seam-Welded Square & Rectangular Tube

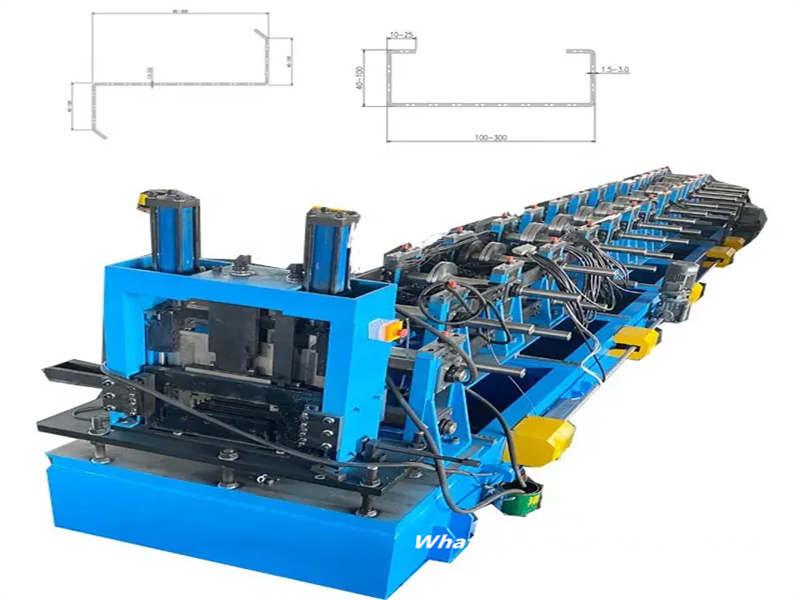

Professional C & Z Purlin Roll Forming Machine Heavy-Duty Automatic Machine for Structural Steel Production

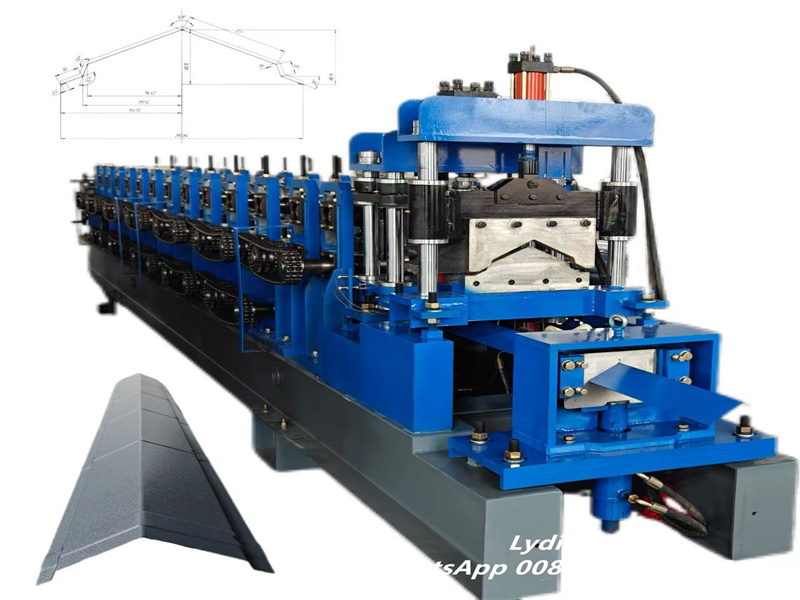

Double-Layer Ridge Capping Roll Forming Machine In modern roofing construction, ridge caps play a critical

STAY IN THE LOOP