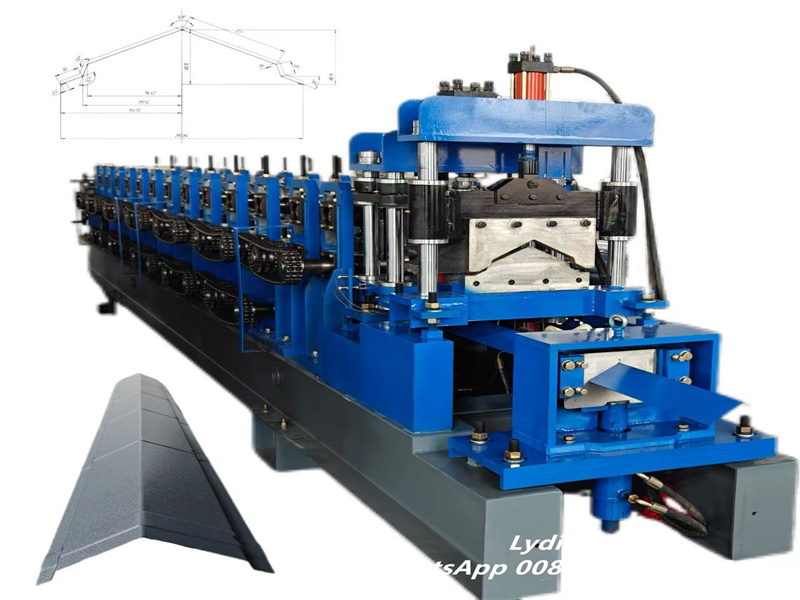

Professional C & Z Purlin Roll Forming Machine

Heavy-Duty Automatic Machine for Structural Steel Production

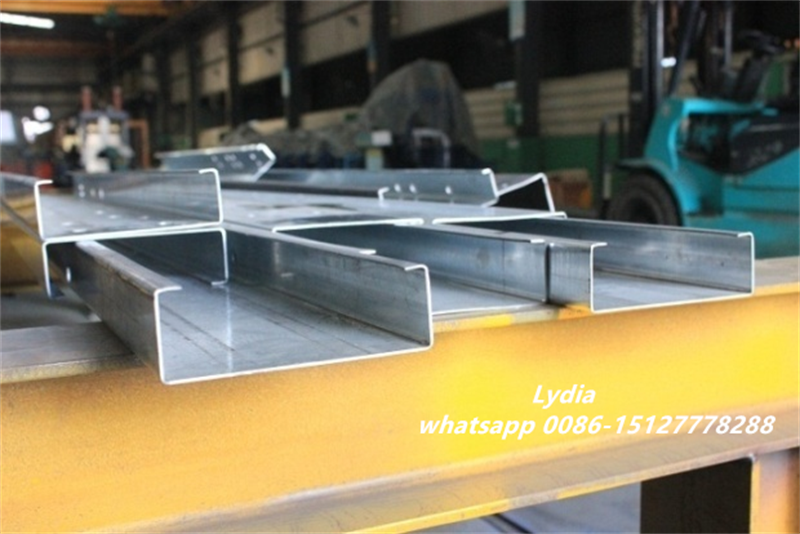

Our Professional C & Z Purlin Roll Forming Machine is a heavy-duty, fully automatic solution developed for manufacturing high-strength C purlins and Z purlins from galvanized steel coils.

It is specifically engineered to process thick materials up to 3.0 mm (11 gauge) with high stability and accuracy.

automatic c and z purlin roll forming machine

As a result, this machine is widely used in steel structure buildings, warehouses, factories, and prefabricated construction projects.

Key Advantages of Our C & Z Purlin Roll Forming Machine

- Processes 1.2–3.0 mm galvanized steel

- Supports 11-gauge maximum thickness

- Produces multiple purlin sizes with one machine

- Automatic C/Z conversion reduces labor cost

- Ideal for heavy-duty structural steel applications

In short, customers can expand their product range while keeping investment costs under control.

Heavy-Duty Design for Thick Steel Materials

Unlike standard roll forming machines, this heavy-duty C Z purlin roll former is designed to handle hard and thick galvanized steel without deformation.

The machine features:

- Reinforced integrated machine frame

- 80 mm solid shafts for high torque transmission

- Precision Cr12 forming rollers with heat treatment

Therefore, it maintains excellent stability during long-term continuous production and heavy-load operation.

automatic c to z changeover purlin roll former

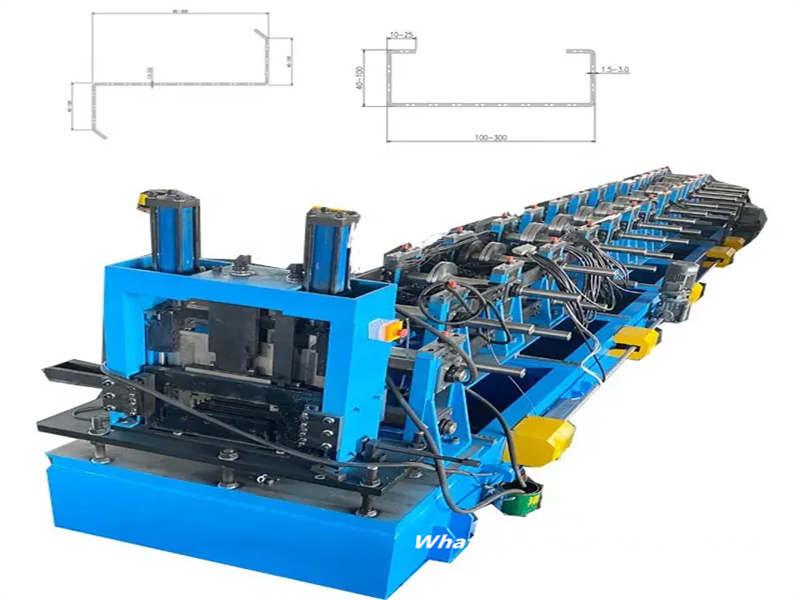

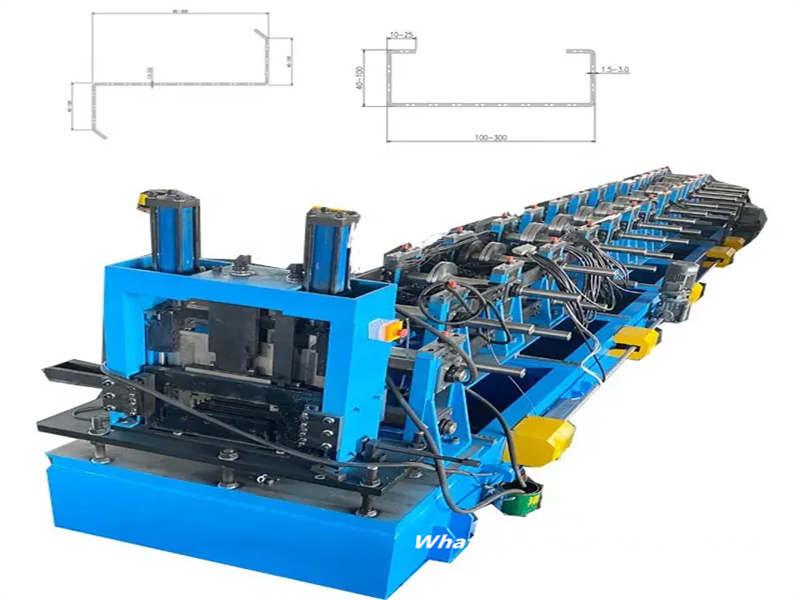

Automatic C to Z Changeover System

The machine is equipped with a PLC-controlled automatic C-to-Z changeover system.

Through the touch screen, operators can switch between C purlin and Z purlin profiles without manual roller replacement or spacer adjustment.

Consequently, production downtime is significantly reduced while flexibility is greatly improved.

Intelligent Control & Automation Features

Auto Gauging System

The automatic gauging system adjusts width and height precisely according to preset parameters.

As a result, profile dimensions remain consistent, even during frequent size changes.

Hands-Free Thread-Up

This function improves operator safety and speeds up coil feeding, making machine startup faster and more reliable.

Touch Screen PLC Control

The machine supports Mitsubishi, Siemens, or Yaskawa PLC systems.

Operators can easily:

- Set profile sizes

- Control punching positions

- Monitor production status in real time

Punching & Cutting System

Flexible Hydraulic Punching

- Punch anywhere along the profile

- Accurate hole positioning for C and Z frames

- Supports customized hole patterns

Clean Hydraulic Cutting

- Burr-free cutting

- High cutting accuracy

- Profiles ready for installation without secondary processing

Therefore, overall production efficiency and finished product quality are both improved.

Technical Specifications

| Item | Specification |

|---|---|

| Machine Type | Heavy Duty C & Z Purlin Roll Forming Machine |

| Raw Material | Galvanized Steel (GI) |

| Material Thickness | 1.2 – 3.0 mm |

| Max Thickness | 11 Gauge |

| Production Speed | 10–20 m/min |

| Roller Stations | 18 stands |

| Shaft Diameter | 80 mm |

| Drive System | Chain Drive |

| Cutting Type | Hydraulic Cutting |

| Roller Material | Cr12 |

| PLC | Mitsubishi / Siemens / Yaskawa |

| Voltage | 380V / 50Hz / 3 Phase (Customizable) |

| Machine Weight | Approx. 11 Tons |

| Warranty | 1 Year |

| Origin | Hebei, China |

Main Machine Components

This C Z purlin making machine includes:

- Coil feeding system

- Precision roll forming unit

- Hydraulic punching system

- Hydraulic cutting device

- PLC electrical control cabinet

- Heavy-duty motor and transmission system

Therefore, the entire production line operates smoothly from feeding to finished purlin output.

Applications

This heavy-duty C & Z purlin roll forming machine is widely used to produce:

- C purlins and Z purlins for steel buildings

- Roof and wall support systems

- Warehouse and factory frames

- Prefabricated steel structure projects

LN Model 80-300 CZ Purlin Machine

As a result, customers receive fully tested equipment ready for installation.

Contact us today to get a customized C & Z purlin roll forming solution and quotation.

Downspout Water Gutter Pipe Making Roll Forming Machine An efficient rainwater drainage system starts with

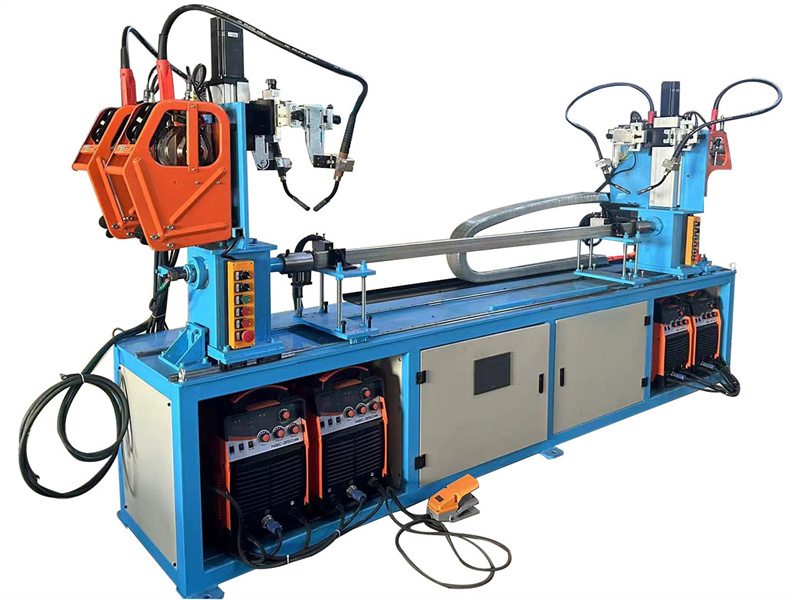

Double-Sided CO₂ / MIG Welding Machine The 2026 New High-Precision Seam-Welded Square & Rectangular Tube

Round Downpipe Roll Forming Machine & Aluminum Gutter Guard Production Line Efficient rainwater drainage is

Double-Layer Ridge Capping Roll Forming Machine In modern roofing construction, ridge caps play a critical

STAY IN THE LOOP