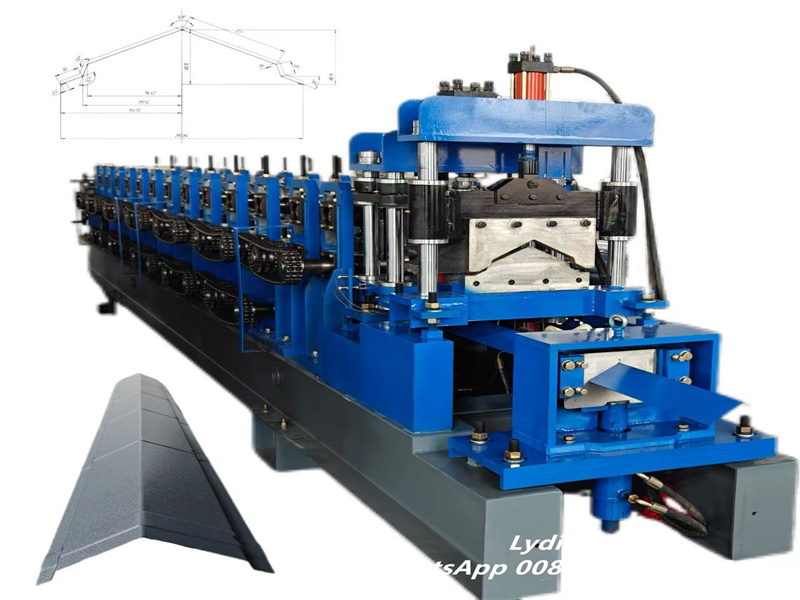

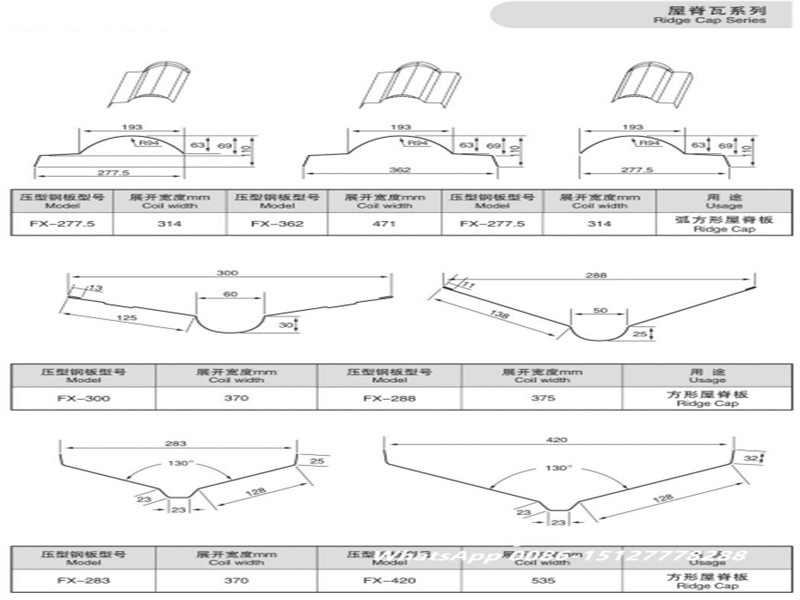

Double-Layer Ridge Capping Roll Forming Machine

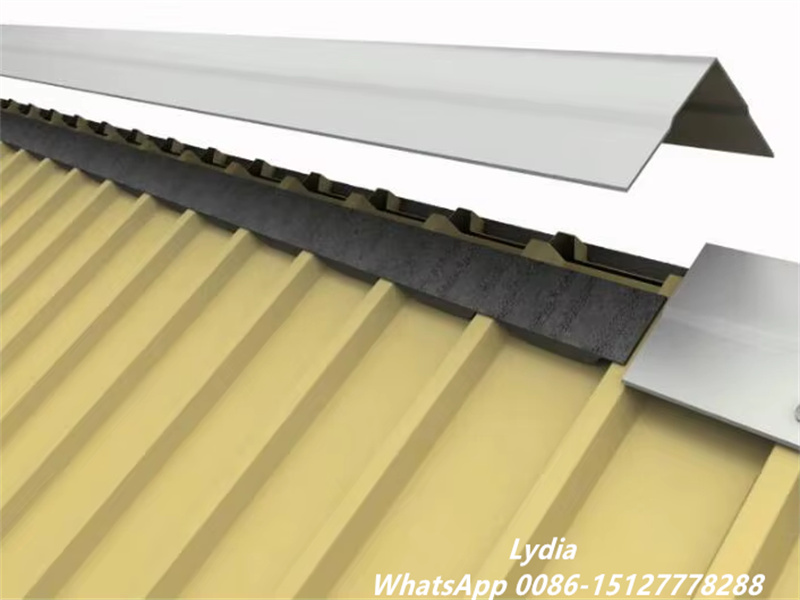

In modern roofing construction, ridge caps play a critical role in sealing roof peaks, preventing water leakage, and enhancing overall structural stability. To meet these requirements, the Double-Layer Ridge Capping Roll Forming Machine provides a reliable, efficient, and flexible Solution for producing high-quality double-layer ridge caps.

This advanced roll forming machine is specifically designed to manufacture ridge capping profiles with a dual-layer structure, combining excellent waterproof performance, improved wind resistance, and an attractive finished appearance. As a result, it is widely used in both residential and industrial roofing projects.

double layer ridge cap machine line

What Is a Double-Layer Ridge Capping Roll Forming Machine?

The Double-Layer Ridge Capping Roll Forming Machine is a specialized production line for building materials that forms metal ridge caps through automated or semi-automated processes. By processing two material layers independently, the machine ensures high precision, stable forming quality, and consistent output.

Moreover, this double-layer design significantly improves roof performance by optimizing drainage, enhancing thermal insulation, and increasing resistance to harsh weather conditions.

roofing ridge cap forming machine

Key Advantages of the Double Layer Ridge Cap Machine Line

Efficient Production

First of all, the machine supports continuous roll forming and automatic cutting. Therefore, it can produce ridge caps in batches with stable quality and reduced labor input.

Optimized Structural Design

Thanks to the double-layer structure, the finished ridge caps offer superior wind resistance and improved water drainage. As a result, roofs remain secure even in extreme climates.

High Material Compatibility

In addition, the machine processes a wide range of materials such as PPGI, GI, and aluminum, making it suitable for different roofing systems and regional standards.

Technical Specifications Overview

| Item | Specification |

|---|---|

| Formed Material | PPGI / GI / Aluminum |

| Material Thickness | 0.4 – 0.8 mm |

| Decoiler | Hydraulic automatic decoiler + free manual decoiler |

| Roller Stations | 14 + 10 rows (customizable) |

| Shaft Diameter | 65 mm solid shaft |

| Roller Material | 45# steel, hard chrome plated |

| Machine Frame | 350H steel |

| Drive System | Chain transmission |

| Cutting System | Automatic cutter, Cr12Mov material |

| Motor Power | 5.5 kW |

| Hydraulic Power | 3 kW |

| Production Speed | 3–5 m/min (depends on cutting length) |

| Voltage | 380V / 50Hz / 3Phase (customizable) |

| Machine Size | 5500 × 1600 × 1600 mm (customized) |

| Machine Weight | About 2.5 tons |

| Control System | PLC automatic control, multi-language support |

Roll Forming Process Workflow Diagram

Decoiler → Leveling → Roll Forming (Upper / Lower) → Automatic Cutting → Stacking

Double Layer Ridge Cap Machine Line: Core Components & Workflow

1. Uncoiling (Decoiling)

At the beginning of the production line, two decoilers feed separate coils for the upper and lower layers. This setup allows different materials or coatings to be used for each layer.

roofing ridge cap forming machine

2. Leveling (Flattening)

Next, precision leveling devices remove coil stress and curvature. As a result, the material enters the forming section perfectly flat, ensuring consistent profile quality.

ridge capping roll forming machine

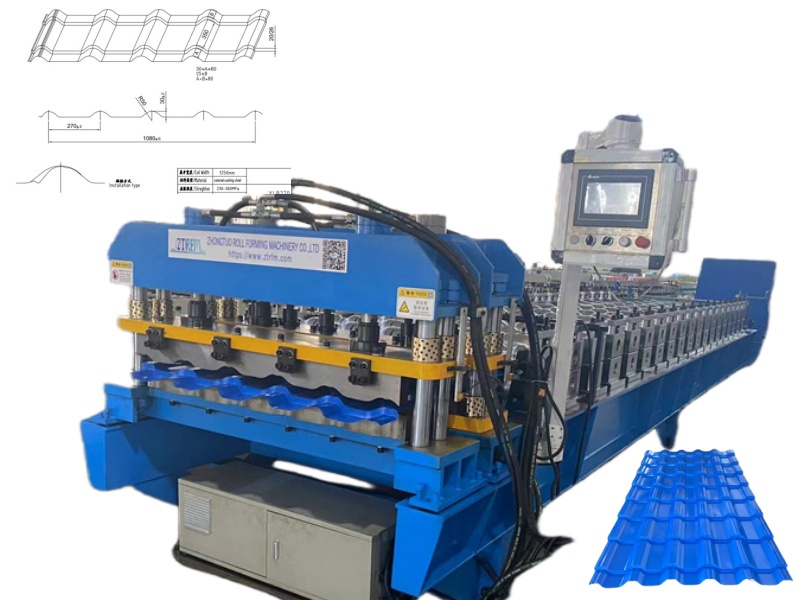

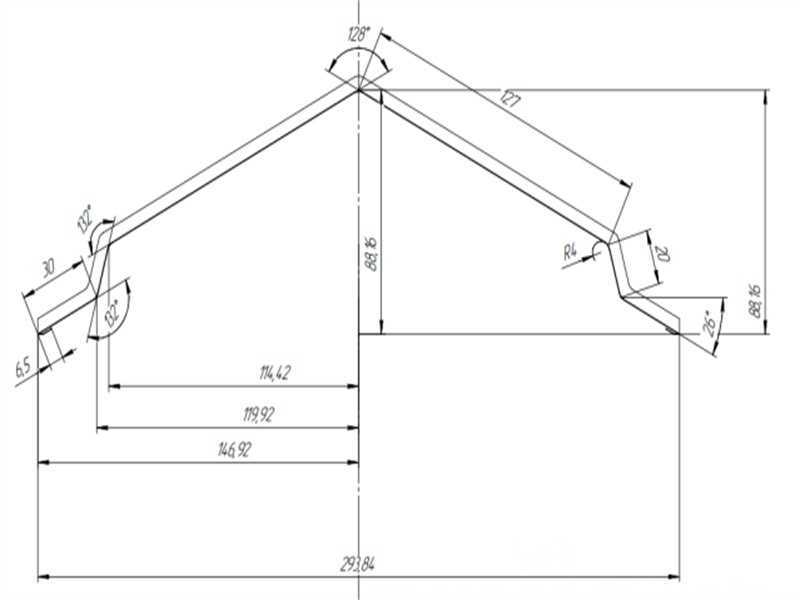

3. Roll Forming – The Core Process

The machine includes two independent roll forming stations:

- Upper Forming Station: Shapes the visible outer ridge cap profile, defining appearance and weather resistance.

- Lower Forming Station: Forms the inner layer, designed for secure installation and structural support.

Importantly, only one forming station operates at a time. Therefore, operators can switch flexibly between upper and lower layer production.

4. Automatic Cutting

After forming, a synchronized cutting system precisely cuts the profile to the preset length. Consequently, every ridge cap fits accurately during installation.

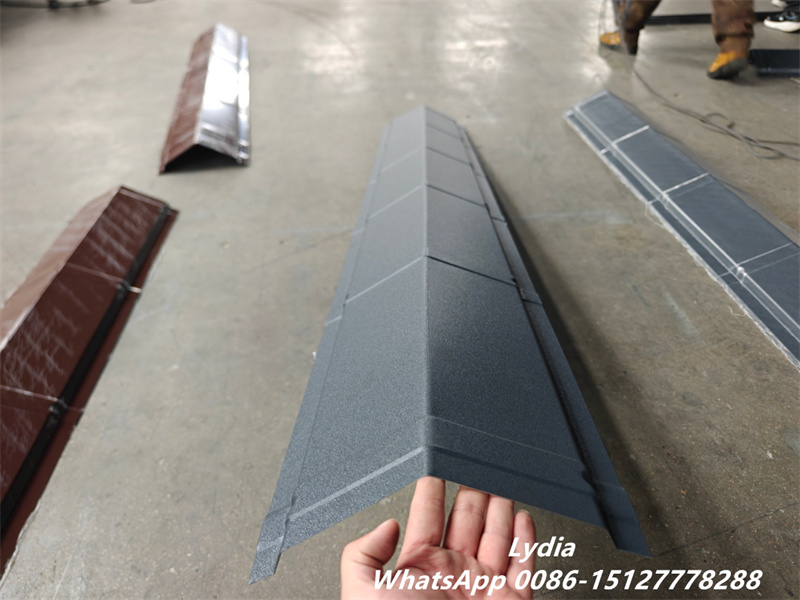

5. Stacking & Packaging

Finally, finished ridge caps are transferred to the stacking system. The machine automatically counts and stacks products, making packaging and transportation easier.

double-layer ridge capping roll forming machine front view

double-layer ridge capping roll forming machine front view

Application Scenarios

Residential Construction

The double-layer ridge capping roll forming machine is ideal for villas, townhouses, and self-built homes. It balances decorative appearance with practical waterproof performance.

Industrial & Commercial Buildings

For factories, warehouses, and large-span steel structures, strong wind resistance is essential. Therefore, metal double-layer ridge caps produced by this machine are the preferred solution.

In summary, the Double-Layer Ridge Capping Roll Forming Machine offers a powerful combination of precision, flexibility, and durability. Whether for residential roofing or large-scale industrial projects, this machine ensures high-quality ridge caps, stable performance, and long-term value.

If you are looking for a reliable double layer ridge cap machine line tailored to your project requirements, this solution is an excellent investment for modern roofing production.

Mangalore Tile Profile Sheet Roll Forming Machine Overview of Mangalore Tile Profile Sheet Roll Forming

Metal Ridge Capping Making Roll Forming Machine Efficient, Accurate & Worry-Free Roofing Profile Machine The

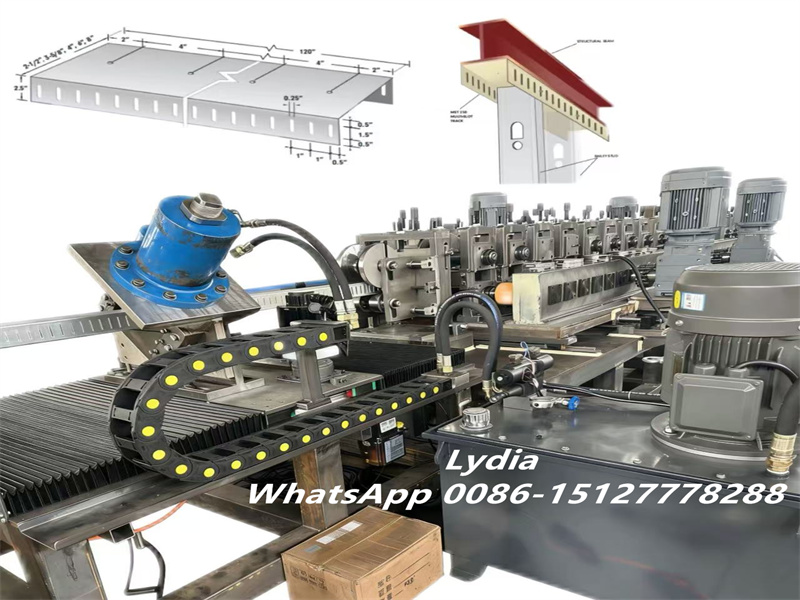

C Channel Light Steel Keel Stud and Track Roll Forming Machine High-Precision Drywall CU/CW Profile

Top Hat Roll Forming Machine The Top Hat Roll Forming Machine is a high-performance production

STAY IN THE LOOP