C Channel Light Steel Keel Stud and Track Roll Forming Machine

High-Precision Drywall CU/CW Profile Manufacturing Machine

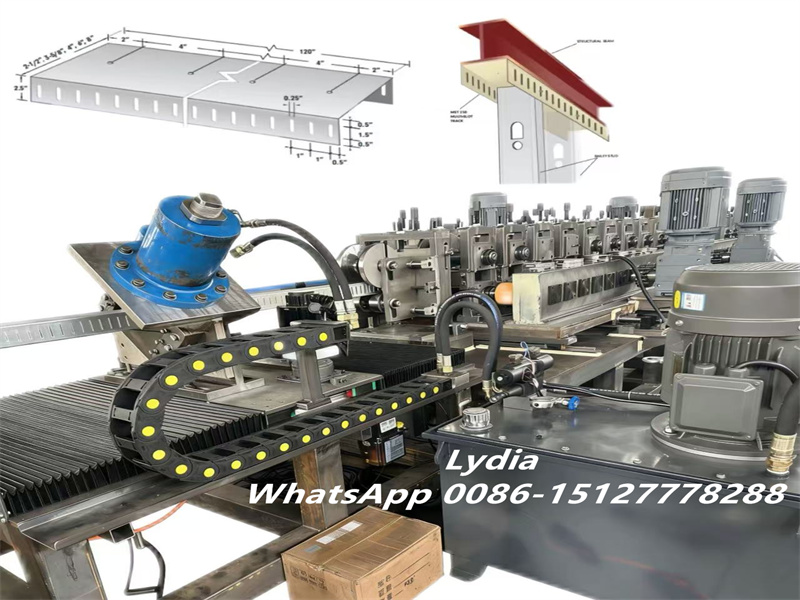

The C Channel Light Steel Keel Stud and Track Roll Forming Machine is designed for efficient, continuous, and fully automated production of drywall CU/CW steel profiles. By integrating advanced CNC control technology with precision mechanical manufacturing, this machine delivers stable performance, millimeter-level accuracy, and consistent product quality for modern construction projects.

Steel keel profile making machine

Steel keel profile making machine

Engineered with an integrated compact structure, the machine occupies minimal floor space while maintaining high output efficiency. It is ideal for large-scale factory production, as well as on-site or emergency engineering processing, offering maximum flexibility for drywall and light steel framing manufacturers.

What Is a C Channel Light Steel Keel Roll Forming Machine?

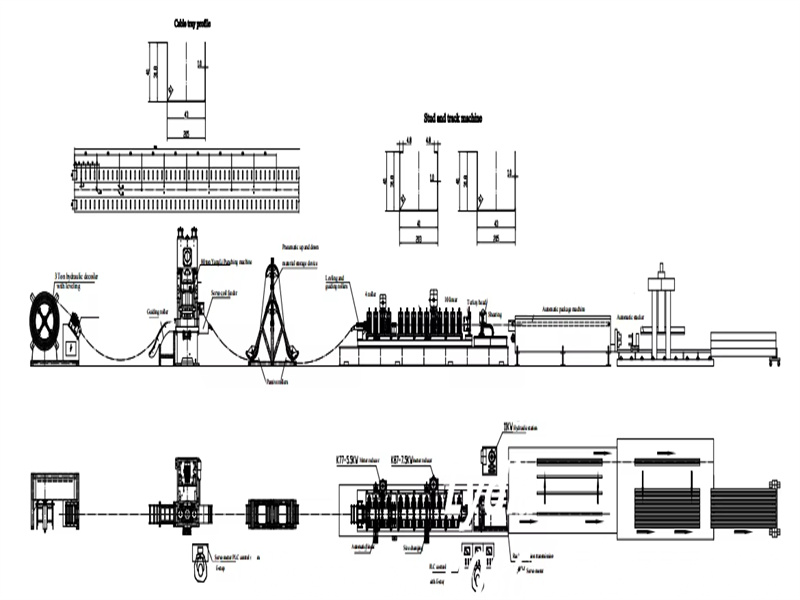

This roll forming machine is used to produce C channel studs and tracks for drywall partition systems. It processes galvanized steel, color steel, or aluminum coils into standardized light steel keel profiles through a continuous forming process — without manual intervention.

Light steel keel roll forming machine

Thanks to its precision roller design and automatic control system, the machine ensures uniform dimensions, smooth edges, and stable profile shapes, laying a solid foundation for standardized and industrialized building construction.

Key Advantages of Our C Channel Roll Forming Machine

Fully Automatic & Easy to Operate

The PLC-controlled system enables automatic feeding, forming, cutting, and output. Operators only need basic training, significantly reducing labor costs and operational errors.

Light steel keel roll forming machine

High Precision Forming

Processing accuracy is controlled at the millimeter level, ensuring excellent consistency between batches and meeting strict construction standards.

Strong & Durable Structure

Manufactured with high-strength components and premium materials, the machine operates smoothly with low maintenance requirements, even in long-term production.

Flexible Customization

Profile size, feeding width, roller steps, voltage, and machine color can all be customized according to project requirements.

Suitable for Multiple Applications

Perfect for drywall partitions, ceiling systems, light steel framing, residential buildings, commercial interiors, and industrial construction projects.

Drywall stud and track machine

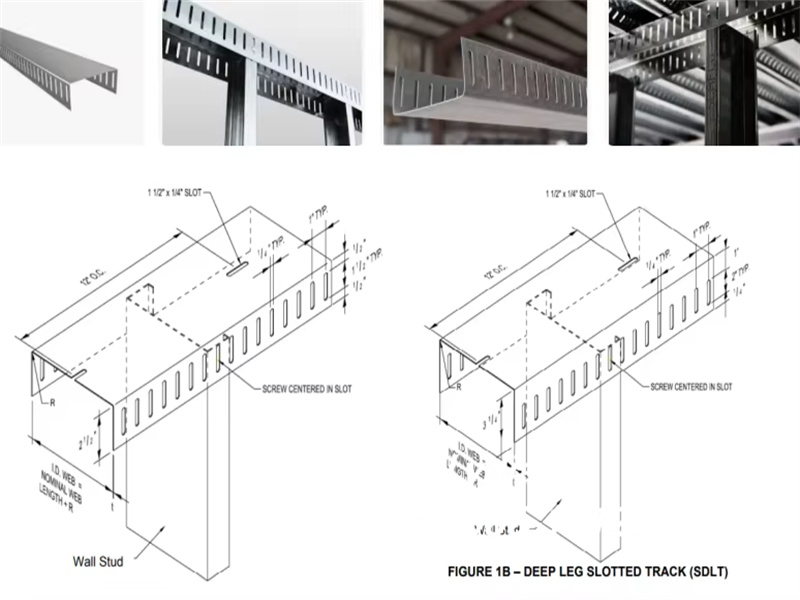

Technical Specifications of Drywall partition system using light steel C-channel studs and tracks

| Item | Specification |

|---|---|

| Machine Type | Drywall CU/CW Roll Forming Machine |

| Profile | C Channel Stud & Track |

| Material Thickness | 0.7 – 1.2 mm (customizable) |

| Feeding Width | As required |

| Feeding Material | Galvanized steel, color steel, aluminum |

| Shaft Material | 45# steel, hard chrome plated |

| Roller Material | Cr12Mov, wear-resistant, no scratches |

| Roller Stations | Customized per profile |

| Drive System | Chain transmission |

| Main Motor Power | 7.5 kW |

| Hydraulic Power | 3 kW |

| Voltage | 380V / 50Hz / 3 Phase (or customized) |

| Machine Weight | Approx. 6500 kg |

| Control System | PLC automatic control |

| Place of Origin | Hebei, China |

| Brand | Zhongtuo (ZTRFM) |

| Warranty | 1 Year |

Core Components

- High-quality motor

- Precision bearings

- Stable hydraulic pump

- Reliable hydraulic cutting system

All core components are carefully selected to ensure long service life and consistent performance.

Quality Assurance & Certification

- CE Certification – Complies with EU standards

- Machinery Test Report – Provided

- Video Outgoing Inspection – Provided before shipment

Each machine undergoes strict inspection before delivery to guarantee performance and reliability.

Packaging & Delivery

- Selling Unit: Single machine set

- Secure packaging for international shipping

- Custom voltage and configuration available

- On-time delivery with professional export packing

CU CW roll forming machineCU

Why Choose Zhongtuo Roll Forming Machines?

With over 12 years of manufacturing experience, Zhongtuo (ZTRFM) is one of the leading factories for building material machinery in China. Our machines are trusted by customers in the United States, Saudi Arabia, Canada, Brazil, and more.

Customers consistently choose us not because we are the cheapest — but because our machines are stable, durable, and worry-free, backed by fast-response after-sales service.

Applications

- Drywall stud & track systems

- Light-gauge steel framing

- Commercial and residential partitions

- Ceiling and interior wall systems

- Modular and prefabricated buildings

Steel keel profile making machine

Metal Ridge Capping Making Roll Forming Machine Efficient, Accurate & Worry-Free Roofing Profile Machine The

Top Hat Roll Forming Machine The Top Hat Roll Forming Machine is a high-performance production

Container house frame making machine Australian specification standards shipping living container house frame making machine is

Specification Standards Shipping Living Container House Frame Making Machine The Australian specification standards shipping living

STAY IN THE LOOP