Specification Standards Shipping Living Container House Frame Making Machine

The Australian specification standards shipping living container house frame making machine is designed to produce container house pillar frames efficiently and automatically.

Therefore, it is widely used in modular housing, prefabricated buildings, and living container house projects that require high strength and stable structural performance.

By using this container house frame-making machine, manufacturers can achieve high output, consistent quality, and precise forming, while fully meeting Australian specification standards.

container house frame making machine

What Is a Living Container House?

A living container house is a modern modular building system developed from shipping containers.

Because of its mobility and flexibility, it can be installed in different locations anytime and anywhere.

Moreover, container houses can integrate:

- Solar photovoltaic panels for power supply

- Solar water heaters for hot water

- Sewage treatment systems for water reuse

As a result, container houses provide a comfortable, energy-efficient, and sustainable living solution.

Depending on the number of occupants, container houses can be customized into different sizes and layouts.

In this article, we take the container house pillar frame as an example to explain how this machine produces it.

container house frame making machine

Container House Frame Making Machine – Design Overview

We designed this container house frame making machine specifically for:

- Thick galvanized steel forming

- High structural strength

- Continuous batch production

- Compliance with Australian standards

Therefore, the entire production line focuses on stability, accuracy, and automation.

Main Technical Parameters (Table Overview)

Below is a clear technical specification table, which allows buyers to quickly understand the machine’s core configuration:

shipping container house frame making machine

Container House Frame Making Machine Technical Parameters

| Item | Specification |

|---|---|

| Machine Type | Container House Frame Making Machine |

| Application | Living container house pillar frame |

| Design Standard | Australian specification standards |

| Raw Material | Galvanized steel sheet |

| Material Thickness | 3.0 – 4.0 mm |

| Material Strength | Q235 |

| Forming Stations | 26 stations |

| Forming Speed | 15 m/min (max up to 25 m/min) |

| Shaft Diameter | 95 mm (quenched & tempered) |

| Roller Material | GCr15, heat-treated & blackened |

| Transmission Type | Gearbox transmission |

| Cutting Type | Hydraulic forming cutting |

| Cutting Blade Material | Cr12MoV, heat treated |

| Cutting Tolerance | ≤ ±2.0 mm |

| Hydraulic Power | 55 kW |

| Control System | PLC + Touch Screen (Delta) |

| Encoder | OMRON |

| Cooling System | Air-conditioning cooling device |

| Finished Table | 3 meters, non-powered |

Key Features of the Container House Frame Making Machine

Stable Gearbox Transmission

The machine adopts gearbox transmission, ensuring even power distribution.

Since the material thickness can reach 4.0 mm, this structure guarantees stable forming and long service life.

Hydraulic Punching and Cutting

In addition, the machine uses hydraulic punching and forming shearing, which effectively prevents profile deformation.

As a result, the finished container house frames maintain accurate dimensions.

High-Precision Rollers and Molds

All rollers and molds are processed with high precision.

Therefore, the finished profiles are accurate, strong, and visually clean.

Reliable Electrical System

We use world-famous brands for motors, PLCs, and electrical components.

Consequently, the machine runs smoothly with low maintenance costs.

container house frame making machine

Machine Composition (Production Line Structure)

The complete container house frame making machine line includes:

- 5T × 600 mm horizontal manual decoiler

- Feeding and positioning device (with double roller tray)

- Five-roll leveling device

- Main roll forming machine (26 stations)

- Five-roll shaping device

- Hydraulic control center with cooling system

- Hydraulic back punching device

- Hydraulic forming cutting system

- PLC control cabinet

- Finished product run-out table

This configuration ensures continuous, stable, and efficient production.

Finished Products & Application

Using this machine, manufacturers can produce container house pillar frames suitable for:

- Shipping living container houses

- Modular residential buildings

- Prefabricated housing systems

- Temporary and permanent container structures

All finished products meet Australian specification standards and ensure high structural safety.

Why Choose This Container House Frame Making Machine?

- Designed for thick, high-strength steel

- Fully automatic and continuous production

- High precision forming and cutting

- Stable hydraulic and gearbox system

- Ideal for Australian standard container house projects

Therefore, it is a reliable solution for companies expanding into the container house and modular construction market.

Container house frame making machine Australian specification standards shipping living container house frame making machine is

Stainless Steel & Aluminum Door Frame Making Machine The stainless steel and aluminum door frame

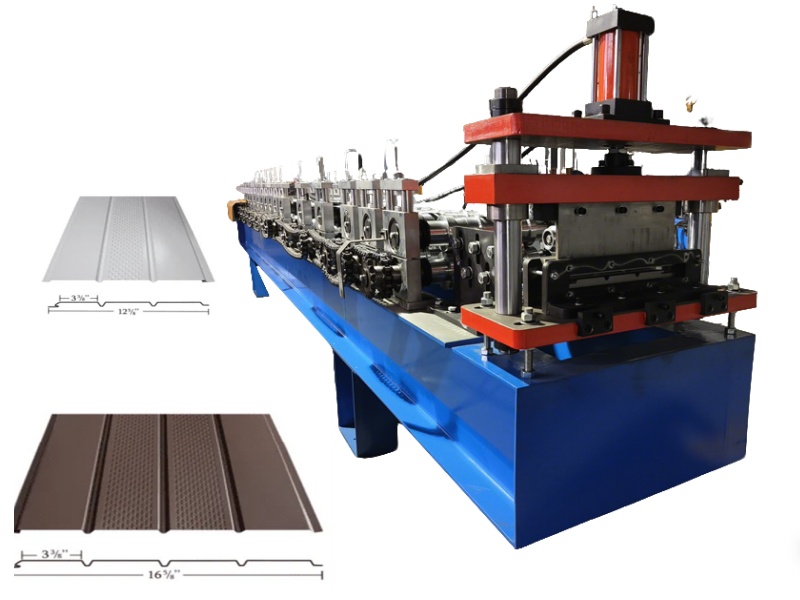

The ZTRFM Soffit Panel Roll Forming Machine is engineered for manufacturers who require fast, stable,

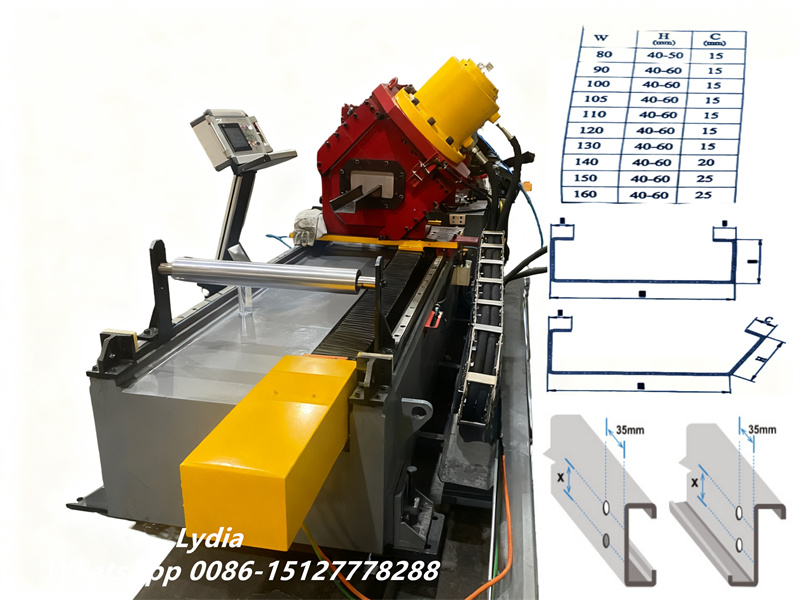

Cee & Zee Eave Struts Roll Forming Machine for Metal Buildings High-Performance Purlin Mill In

STAY IN THE LOOP