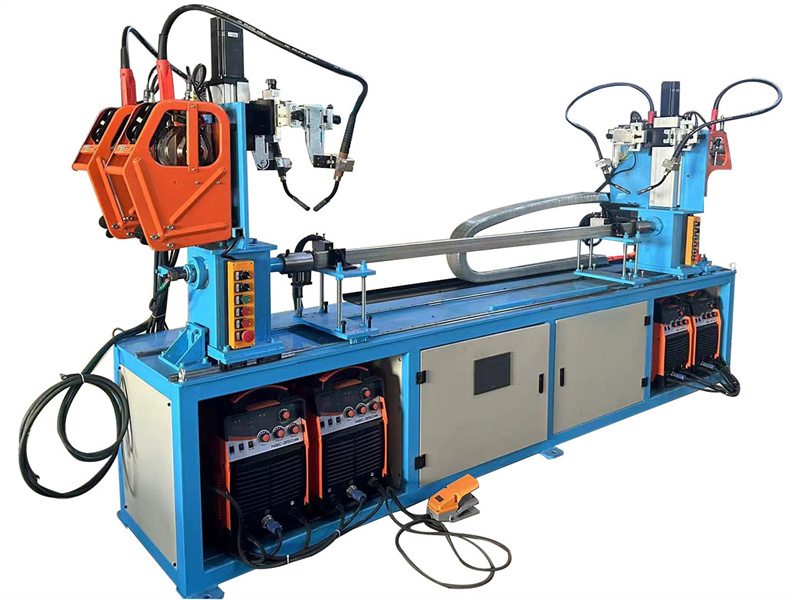

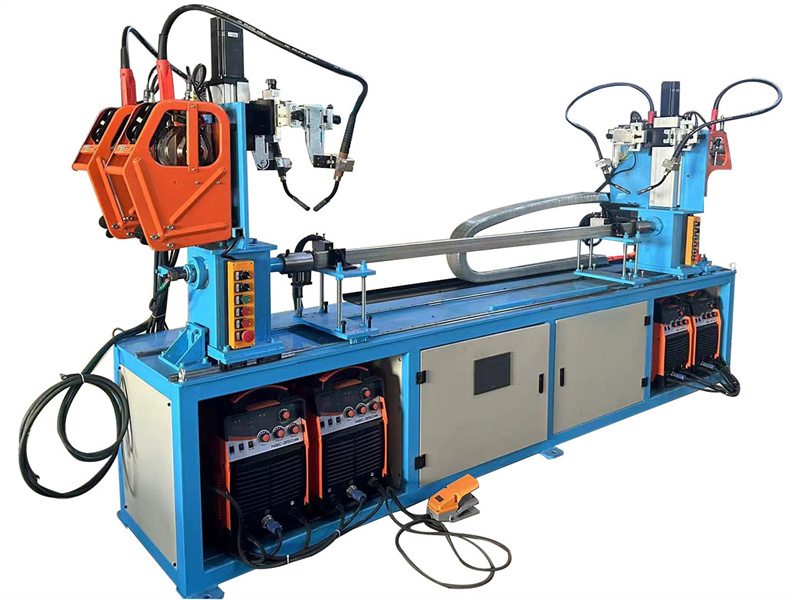

Double-Sided CO₂ / MIG Welding Machine

The 2026 New High-Precision Seam-Welded Square & Rectangular Tube Making Machine is engineered for manufacturers who require high welding accuracy, strong seam integrity, and stable mass production.

Developed by CANGZHOU ZHONGTUO ROLL FORMING MACHINERY CO., LTD, this machine integrates double-sided synchronous welding, a rigid mold-fixing system, and advanced CO₂ / MIG welding technology, making it ideal for modern steel tube fabrication plants.

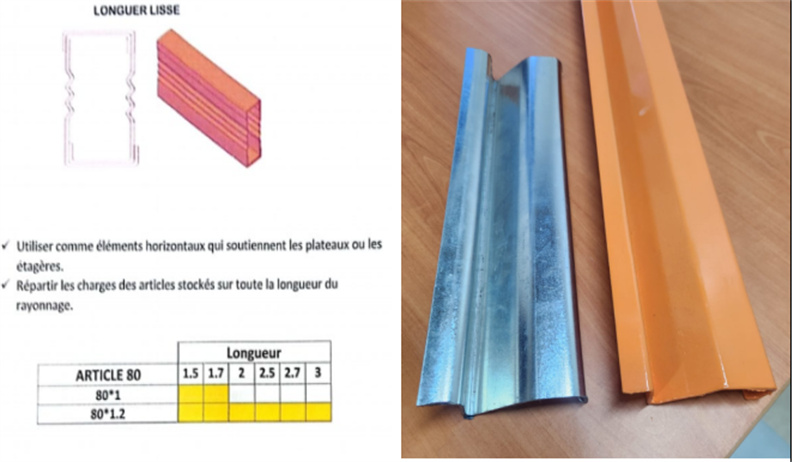

high precision seam welded square rectangular tube making machine

High-Speed Seam Welding Solution for Square & Rectangular Tubes

This machine is specifically designed for square and rectangular steel tubes that demand clean, uniform, and high-strength weld seams.

Unlike traditional single-side welding equipment, it adopts dual welding guns on both sides, enabling simultaneous welding.

As a result:

- Welding time is significantly reduced

- Seam symmetry and strength are improved

- Welding deformation is effectively minimized

double sided welding square tube seam welding machine

Moreover, the fixed-mold welding structure ensures accurate tube positioning throughout the entire process.

Key Advantages of the Seam-Welded Tube Machine

Double-Sided Synchronous Welding

The machine uses two welding guns working simultaneously on both sides, which:

- Dramatically shortens welding cycles

- Enhances seam strength and penetration

- Ensures repeatable, stable welding quality

The seam-welded tube making machine can operate as:

- A standalone welding unit, or

- An integrated part of a complete tube mill production line

Thanks to its industrial-grade structure and stable control system, it supports long-term continuous operation with consistent weld quality.

custom square rectangular tube welding machine zhongtuo

High-Precision Mold-Fixing Structure

With customized welding molds:

- Tubes are firmly clamped during welding

- Weld seams remain straight and uniform

- Dimensional accuracy is strictly controlled

Therefore, finished tubes meet high industrial standards without rework.

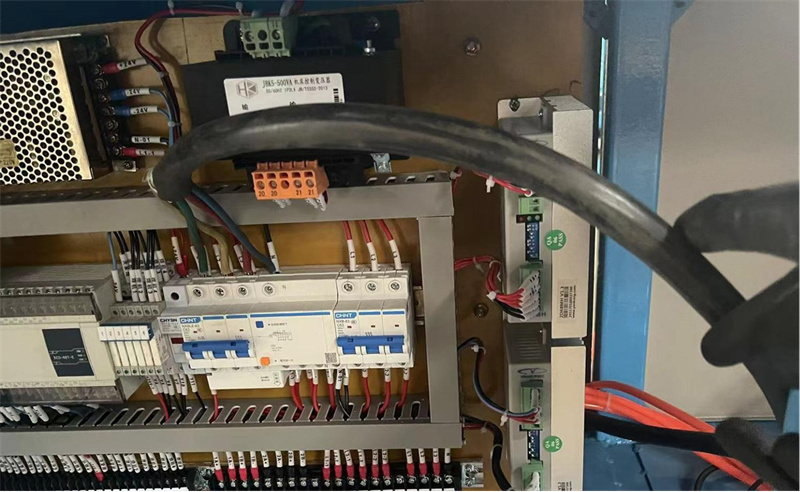

Powerful CO₂ / MIG Welding System

To meet heavy-duty production demands, the machine is equipped with:

- 6 sets of 350A CO₂ / MIG welding machines

- Welding length range from 500 mm to 3500 mm

- Stable arc performance for continuous operation

industrial square rectangular tube seam welding machine

Fully Customized Manufacturing

As a direct manufacturer, Zhongtuo provides customized solutions based on:

- Tube size and cross-section

- Required welding length

- Production capacity

- Factory layout and automation level

Consequently, each machine is optimized for the customer’s real production needs.

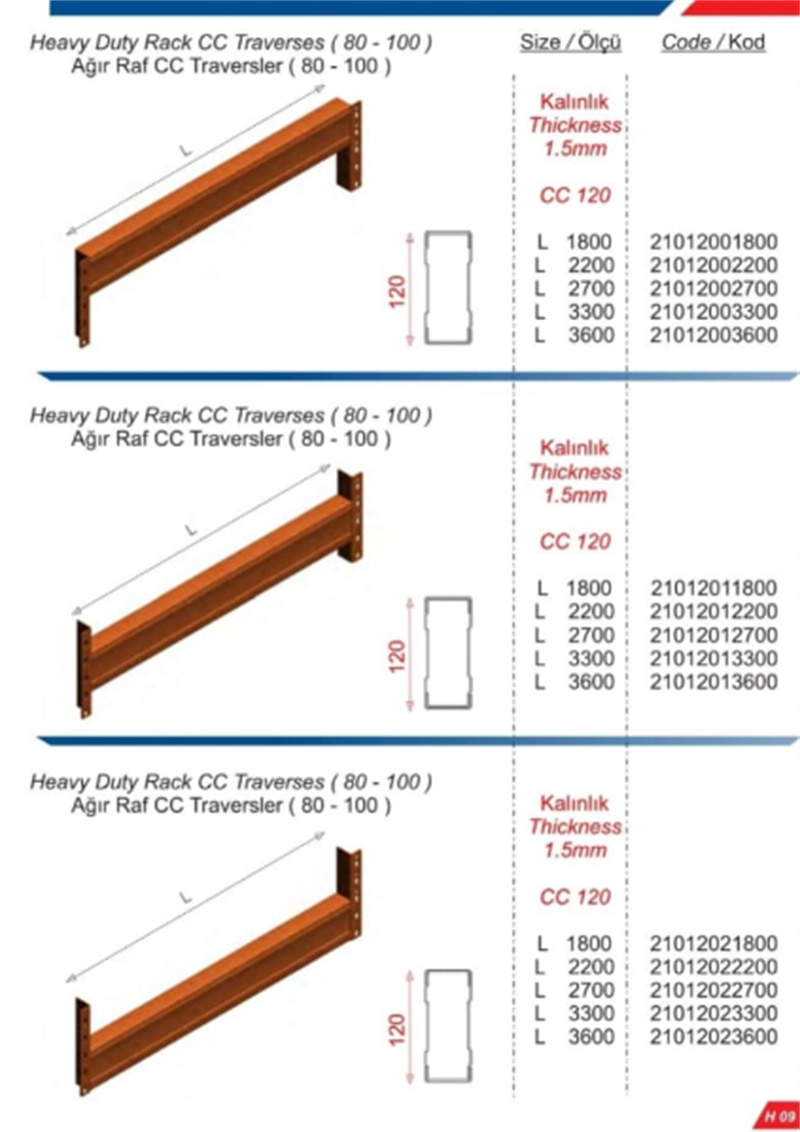

Technical Specifications of custom square rectangular tube welding machine

| Item | Specification |

|---|---|

| Machine Type | Seam-Welded Square & Rectangular Tube Making Machine |

| Welding Method | CO₂ / MIG Welding |

| Welding Guns | Double-sided, synchronous |

| Welding Power | 6 × 350A welding machines |

| Welding Length | 500 – 3500 mm |

| Applicable Profiles | Square & Rectangular Tubes |

| Power Supply | 380V / 50Hz |

| Gas Source | Carbon Dioxide (CO₂) |

| Control Type | Industrial electrical control system |

| Customization | Available |

Installation Options

- On-site installation by Zhongtuo engineers

- Remote installation guidance with full documentation

double-sided welding square tube seam welding machine

Why Choose Zhongtuo Seam-Welded Tube Machines?

With over 18 years of manufacturing experience, Zhongtuo offers:

- Factory-direct pricing

- Strict quality control

- Professional customization capability

- Reliable global after-sales service

CTA

📩 Contact us now to get a customized seam-welded tube making solution and a competitive quotation.

Downspout Water Gutter Pipe Making Roll Forming Machine An efficient rainwater drainage system starts with

Professional C & Z Purlin Roll Forming Machine Heavy-Duty Automatic Machine for Structural Steel Production

Round Downpipe Roll Forming Machine & Aluminum Gutter Guard Production Line Efficient rainwater drainage is

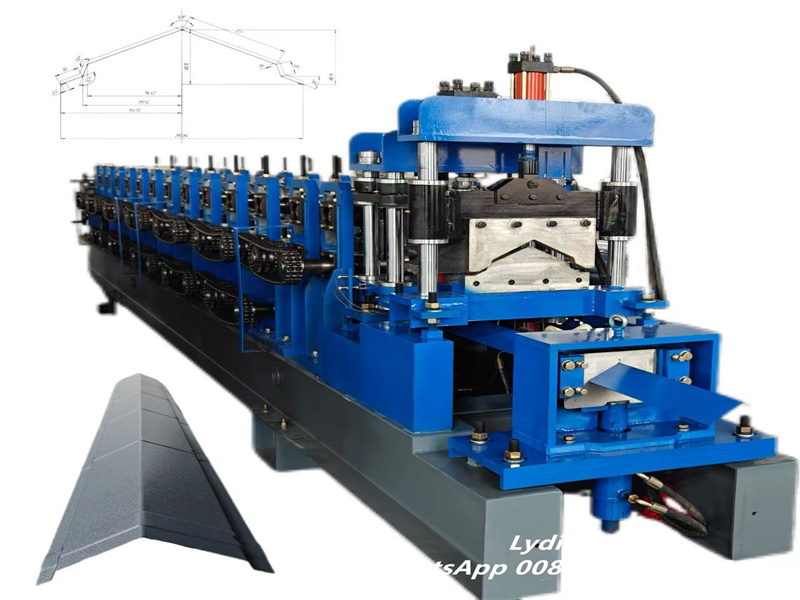

Double-Layer Ridge Capping Roll Forming Machine In modern roofing construction, ridge caps play a critical

STAY IN THE LOOP