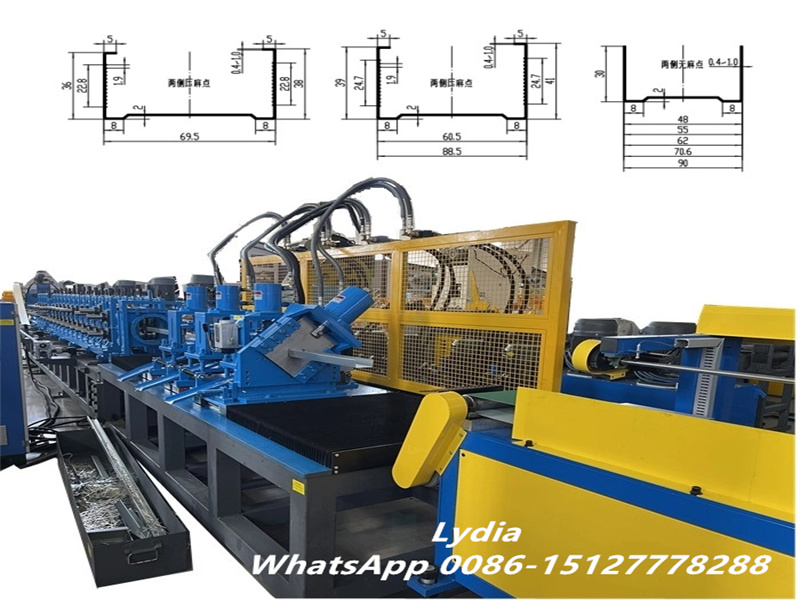

Drywall Stud and Track Roll Forming Machine High-Speed Light Steel Keel Production Line

Our Drywall Stud and Track Roll Forming Machine is specially engineered for producing metal studs and tracks used in drywall and ceiling framing systems. This purlin-type roll forming machine with a cassette system offers quick size changes, high accuracy, and stable performance. It is widely used in light steel keel roll forming, metal framing production, and the manufacture of construction profiles.

Drywall Stud and Track Roll Forming Machine

With an advanced servo-driven PLC system, the line supports automatic size adjustment, remote control, and real-time diagnostics, ensuring efficient and precise operations. Depending on your needs, the system can run at 10–15 m/min (standard) or reach 70 m/min fully automatic production with a stacker, allowing one operator to manage the entire process.

Drywall Stud and Track Roll Forming Machine

Drywall Stud and Track Roll Forming Machine

Technical Specifications of light steel keel roll forming machine

| Item | Specification |

|---|---|

| Profiles | Stud (C with lip) & Track (U) |

| Web Sizes | 2½″, 3 5/8″, 6″, 8″ |

| Flange | 1¼″ fixed |

| Lip (Stud) | 9–10 mm |

| Thickness | 0.45–0.90 mm (25–20 ga) |

| Forming Stations | 12–14 stations |

| Rollers | Cr12MoV, HRC 58–62, polished |

| Shaft Diameter | ≥75 mm |

| Drive System | Cardan shaft drive (no chains) |

| Cutting | Hydraulic guillotine, SKD11/D2 blades |

| Punching | Web oval holes Ø35–40 mm, side flange holes with emboss |

| Motor Power | 7.5–15 kW Siemens / ABB / Yaskawa + VFD |

| Hydraulics | Yuken / Rexroth / Nachi, 10–12 MPa, with oil cooler |

| Production Speed | 10–15 m/min (standard) / 70 m/min (high-speed) |

| Length Range | 0.3–6.0 m, programmable |

| Run-out Table | 3–6 m, optional automatic stacker |

| Electrical | UL/cUL/CSA certified, UL508A / CSA C22.2 compliant |

| Safety | Lockable main switch, e-stop, safety covers, interlocks |

Applications of drywall stud and track roll forming machine

-

Drywall partition framing for offices, factories, and residential housing

-

Ceiling construction systems with gypsum board, calcium silicate board, fiber cement board

-

Light gauge steel framing for warehouses, commercial spaces, and greenhouses

-

Metal stud and track production for North American and global markets

Advantages of Floor Deck Roll Forming Machine When it comes to modern construction projects, Floor

Full-Automatic T18/T35 IBR Roofing Sheet Roll Forming System with Dual-Layer Capability This advanced roll forming

The ZTRFM heavy-duty coil recoiler is engineered for handling narrow-width and light-gauge strip materials, ensuring

The metal coil slitting and recoiling machine is designed for processing narrow-width strips with high

STAY IN THE LOOP