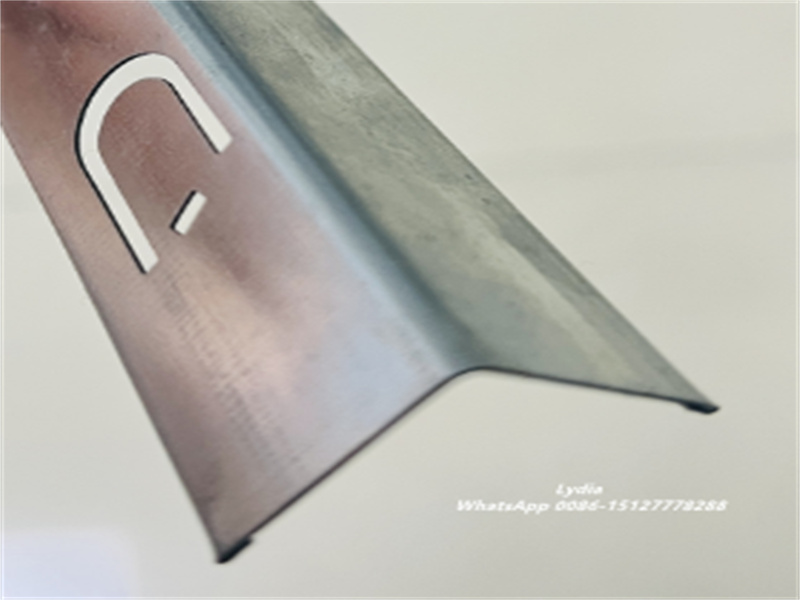

Aluminum Corner Roll Forming Machine

The Aluminum Corner Roll Forming Machine is a precision-engineered production line designed for the efficient manufacturing of aluminum or galvanized steel corner profiles. This machine integrates decoiling, punching, roll forming, hydraulic cutting, and automatic stacking in one continuous process. With stable transmission, high accuracy, and durable components, it is an ideal solution for producing construction corner trims with consistent quality.

Aluminum Corner Roll Forming Machine

Features & Advantages of the Aluminum Corner Roll Forming Machine

- High Precision: Length tolerance within ±1mm.

- Durable Rollers: Cr12MoV rollers, quenched and CNC-machined, ensuring long service life.

- Stable Drive System: Equipped with domestic gear reducer for silent and reliable performance.

- Automation Control: PLC + touch screen system (Inovance), with German Sick encoder and Schneider components.

- Flexible Operation: Easy adjustment, safe guarding mesh, and compact line layout.

Aluminum Corner Roll Forming Machine

Technical Parameters of Aluminum Corner Roll Forming Machine

| Item | Specification |

|---|---|

| Material | Galvanized Steel Strip |

| Thickness | 0.3 – 0.5 mm |

| Width | Customizable (per profile design) |

| Production Length | 1 m (adjustable) |

| Length Tolerance | ±1 mm |

| Forming Speed | 9 – 12 m/min |

| Transmission | Gear Reducer, Silent Type |

| Power | 4 kW Main Motor + 2.2 kW Hydraulic Pump |

| Line Length | 12 – 15 m |

Aluminum Corner Roll Forming Machine

Machine Components

- Decoiler (1 set): Manual expansion, motorized decoiling, coil inner diameter φ460–520 mm, max OD 1400 mm, max weight 2T.

- Servo Feeder NC-200: Inovance or equivalent servo system, max width 200 mm, thickness range 0.3–1.2 mm.

- Punching Station: 25T punching press with punching die set.

- Roll Forming System: 10 forming stations, Cr12MoV rollers, quenched HRC60–62, CNC precision-machined.

- Roller Shafts: Material 40Cr, diameter φ42 mm, tempered, finely ground.

- Machine Frame: Solid welded steel structure, stress relieved and CNC-milled.

- Side Plates: 45# precision guide columns, 45 mm thickness, with scale dial gap adjustment.

- Forming Motor: 4 kW, 380V, 50Hz, domestic brand.

- Hydraulic Cutting: 2.2 kW hydraulic station, equipped with mold set.

- Run-out Table: 1.5 m with measurement ruler + simple platform 1 m.

- Electrical System: PLC (Inovance), touch screen (Inovance), encoder (Sick), VFD (Inovance), Schneider components.

- Safety Protection: Net guard for forming section.

Aluminum Corner Roll Forming Machine

Aluminum Corner Roll Forming Machine

Aluminum Corner Roll Forming Machine

Advantages of Floor Deck Roll Forming Machine When it comes to modern construction projects, Floor

Full-Automatic T18/T35 IBR Roofing Sheet Roll Forming System with Dual-Layer Capability This advanced roll forming

The ZTRFM heavy-duty coil recoiler is engineered for handling narrow-width and light-gauge strip materials, ensuring

The metal coil slitting and recoiling machine is designed for processing narrow-width strips with high

STAY IN THE LOOP