Enhanced Description of Load Bearing Stud Framing Roll Forming Machine

The Load Bearing Stud Framing Roll Forming Machine is a highly efficient and precision-engineered solution designed for the production of heavy-gauge metal studs and structural framing systems. Manufactured by ZTFRM, this roll forming equipment supports steel thicknesses ranging from 20 gauge (33 mils) to 10 gauge (118 mils), making it ideal for industrial and commercial construction applications.

ZTFRM’s Load Bearing Stud Framing Roll Forming Machine integrates advanced automation with a PLC control system to ensure consistent product quality and high-speed output. The entire forming process is streamlined—from decoiling and feeding to roll forming, cutting, and discharging—providing a one-stop solution for steel frame manufacturing.

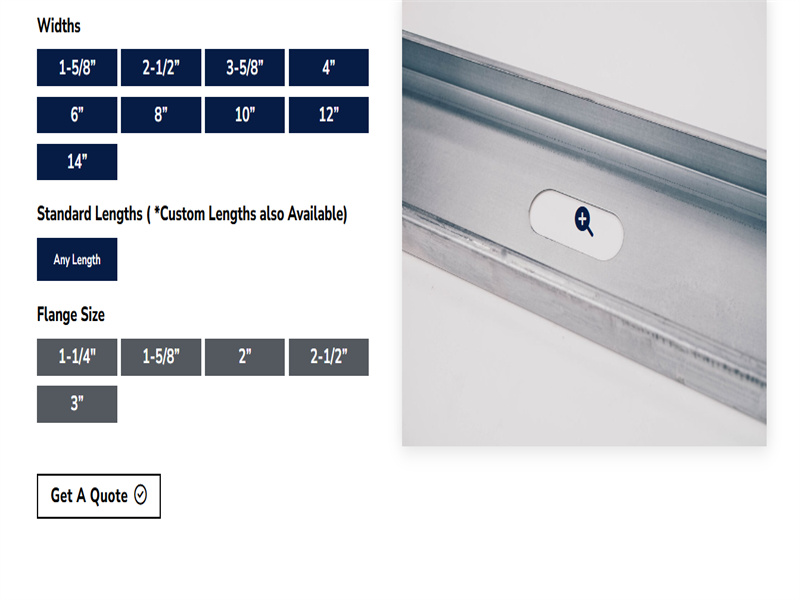

This metal stud roll forming machine complies with industry-leading standards such as ASTM, ICC, and UL. It can produce various flange widths (1-3/8”, 1-5/8”, 2”, 2-1/2”, 3”) and depths (7-1/4″, 9-1/4″, 11-1/2″, 13-1/2″, 14″) to meet the diverse demands of structural framing applications.

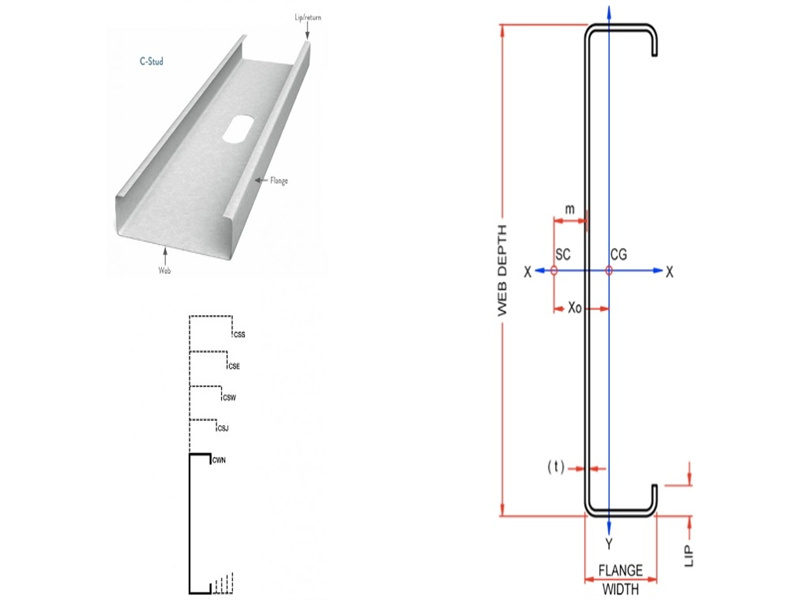

The Drawing Profile

Whether you are fabricating exterior curtain walls, axial load-bearing structures, or interior support walls, the Load Bearing Stud Framing Roll Forming Machine delivers unmatched reliability, strength, and efficiency. ZTFRM ensures that every steel stud framing machine is designed with durability and user-friendly control in mind.

The workflow of the Roll Forming Machine:

The Load Bearing Stud Framing Roll Forming Machine is a highly efficient and precision-engineered solution designed for the production of heavy-gauge metal studs and structural framing systems. Manufactured by ZTFRM, this roll forming equipment supports steel thicknesses ranging from 20 gauge (33 mils) to 10 gauge (118 mils), making it ideal for industrial and commercial construction applications.

Advantages of Floor Deck Roll Forming Machine When it comes to modern construction projects, Floor

Full-Automatic T18/T35 IBR Roofing Sheet Roll Forming System with Dual-Layer Capability This advanced roll forming

The ZTRFM heavy-duty coil recoiler is engineered for handling narrow-width and light-gauge strip materials, ensuring

The metal coil slitting and recoiling machine is designed for processing narrow-width strips with high

STAY IN THE LOOP