High Speed Mexico R101 And R72 Trapezoidal Profile Roofing Sheet Making Machine

Decoiler: Φ450–550 mm manual stand or hydraulic unwinder for steady feeding.

Feeding & Leveling: Pre‑sliding cutter and guide rails protect edges and align material.

Forming Unit: 18 chrome‑plated roll passes on precision 70 mm shafts.

Shear: 4 kW hydraulic pump with Cr12 blades for clean, distortion‑free cuts.

Control Cabinet: Delta PLC with Omron encoder, recipe storage, and multilingual touch interface.

Align & Level strip via guide rails and leveling rollers.

Form Profile through 18 roll stations (swap molds for R101/R72).

Shear & Punch (optional) with automatic hydraulic cutter.

Collect Panels on a run‑out table or powered stacker.

Mexico R101 and R72 Roof sheet roll forming machine delivers both R101 (1 250 mm) and R72 (914 mm) trapezoidal profiles on one line. Built on a welded H‑beam frame with 70 mm hardened shafts and 18 forming stations, it handles 0.3–0.8 mm PPGI, GI, or Aluzinc steel at up to 15 m/min. With a manual or hydraulic decoiler, PLC control, hydraulic shear, and optional stacker, changeovers take under 20 minutes.

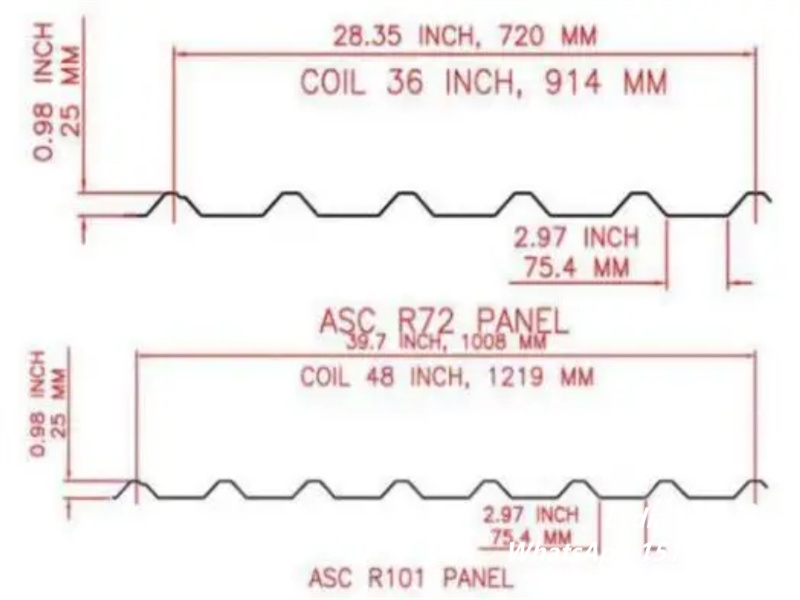

The Drawing Profile:

Mexico R101 and R72 Roof sheet roll forming machine for Specifications

| Specification | Detail |

| Profiles | R101 (1 250 mm) & R72 (914 mm) |

| Material Thickness | 0.3–0.8 mm |

| Forming Stations | 18 |

| Shaft Diameter | 70 mm |

| Main Motor | 5.5 kW |

| Hydraulic Unit | 4 kW |

| Line Speed | Up to 15 m/min |

| Decoiler | 5 T manual or motorized |

| Control | Delta PLC + 5.7″ touchscreen |

| Cutting Accuracy | Hydraulic shear, ±2 mm |

| Frame | 16 mm wall‑plate H‑beam |

| Dimensions | ≈ 6 200×850×1 500 mm |

| Weight | ≈ 3.5 T |

| Power Supply | 380 V/50 Hz/3 phase |

| Warranty | 12 months |

| Certifications | CE, ISO |

Mexico R101 and R72 Roof sheet roll forming machine

Applications of Mexico R101 and R72 Roof sheet roll forming machine

Commercial & Industrial Roofing: Warehouses, factories, large sheds.

Residential & Agricultural: Homes, barns, farm buildings.

Export Markets: Meets international specs for distributors.

Turnkey Projects: Fast installation and profile changes for build‑to‑order lines.

Advantages of Floor Deck Roll Forming Machine When it comes to modern construction projects, Floor

Full-Automatic T18/T35 IBR Roofing Sheet Roll Forming System with Dual-Layer Capability This advanced roll forming

The ZTRFM heavy-duty coil recoiler is engineered for handling narrow-width and light-gauge strip materials, ensuring

The metal coil slitting and recoiling machine is designed for processing narrow-width strips with high

STAY IN THE LOOP