Tr4 Trapezoidal Roof Sheet Roll Forming Machine Analysis

The TR4–TR6 series trapezoidal profile former combines speed, durability, and flexibility for roofing applications. Equipped with rugged 80 mm shafts and interchangeable manual or hydraulic decoilers, the line processes GI, PPGI, or G550 steel up to 1.0 mm thick at 15–25 m/min. A sturdy H‑beam frame, distortion‑free hydraulic shear, and modular stacking tables ensure consistent, high-quality output. With CE/ISO certifications and a two-year warranty, it excels in both Latin American and global roofing markets.

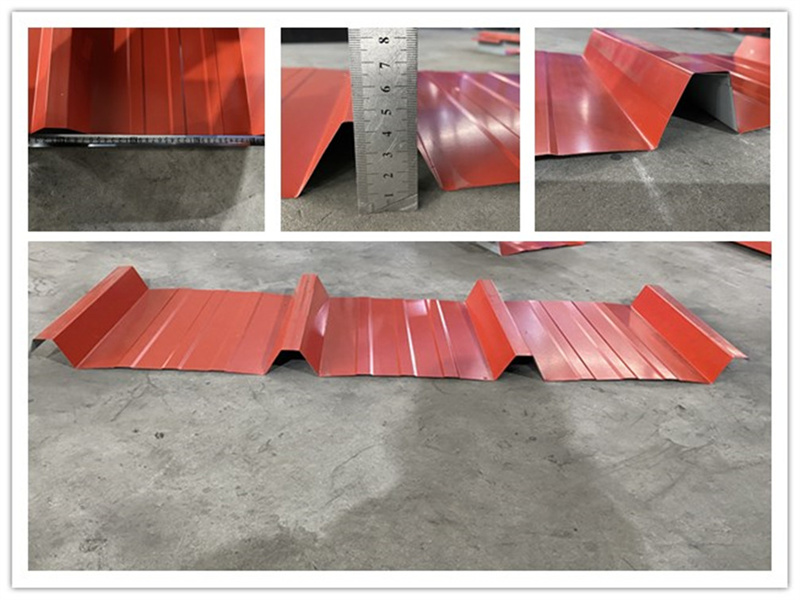

The Drawing Profile of Tr4 Trapezoidal Steel Profile Roll Forming Machine with 80 mm Shafts

Designed specifically for standard TR4 trapezoidal panels, this machine utilizes heat-treated 80 mm rollers for precise profile dimensions over extended runs. It accommodates coil thicknesses between 0.3 and 1.0 mm and achieves throughput rates of 15–25 m/min. Both manual and hydraulic decoilers support diverse coil feeding options, including galvanized or pre-painted steel.

Core Components of Tr4 Trapezoidal Steel Profile Roll Forming Machine

- Roll Forming Unit: 13–15 chrome-plated 45# steel rolls shape material gradually, reducing surface wear.

- Hydraulic Cut-Off Section: A 4 kW pump drives GCr12MoV blades to make clean cuts without deforming profiles.

- Drive & Control System: PLC with touchscreen interface manages a 4 kW main motor and quiet chain transmission.

- Frame & Roller Shafts: Built on a welded H-beam foundation, shafts are heat-treated to HB280 to extend service life.

Performance Specifications of Tr4 Trapezoidal Steel Profile Roll Forming Machine

Here’s the markdown-formatted specification table:

| Specification | Detail |

|---|---|

| Profiles | TR4, TR5 & TR6 trapezoidal shapes |

| Thickness Range | 0.3–1.0 mm |

| Production Speed | 15–25 m/min |

| Forming Stations | 13–15 |

| Roller Shaft Diameter | 80 mm |

| Roll & Shaft Material | 45# steel with chrome finish |

| Cutting Power | 4 kW hydraulic unit |

| Decoilers | Manual stand or hydraulic unwinder |

| Stacking Options | Manual run‑out table or powered stacker |

| Control Platform | PLC with touchscreen |

| Warranty | 2 years |

| Certifications | CE, ISO |

Production Workflow of Tr4 Trapezoidal Steel Profile Roll Forming Machine

- Decoiling: Place coil on the chosen decoiler.

- Pre-Leveling: Remove pre-bend by running material through leveling rollers.

- Profile Rolling: Strip passes through 13–15 roll pairs to form the trapezoidal shape.

- Punching & Cutting: Optional hole punching precedes hydraulic shear cutting.

- Stacking: Collect finished sheets on either a manual table or automated stacker.

Advantages of Tr4 Trapezoidal Steel Profile Roll Forming Machine

– High Throughput: European-standard parts double output compared to older systems.

– Quick Setup: Modular design and pre-wired controls minimize installation time.

– Tight Tolerances: Hardened shafts and accurate roll alignment keep variences within ±1 mm.

– Energy Savings: Optimized motors lower power consumption for continuous operations.

– Extended Lifespan: Durable GCr12MoV blades and chrome-plated rollers resist wear.

Advantages of Floor Deck Roll Forming Machine When it comes to modern construction projects, Floor

Full-Automatic T18/T35 IBR Roofing Sheet Roll Forming System with Dual-Layer Capability This advanced roll forming

The ZTRFM heavy-duty coil recoiler is engineered for handling narrow-width and light-gauge strip materials, ensuring

The metal coil slitting and recoiling machine is designed for processing narrow-width strips with high

STAY IN THE LOOP