TR4 and TR5 Trapezoidal Double Layer Roll Forming Machine Overview

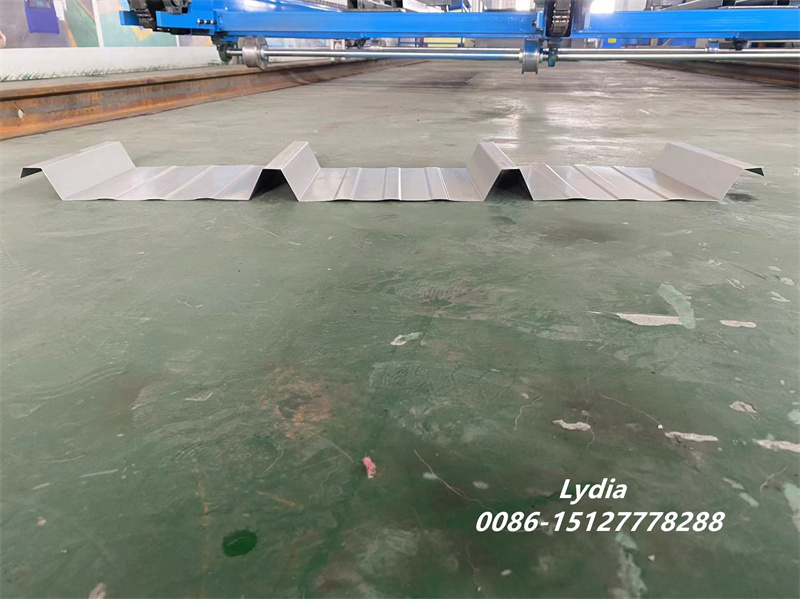

Our 4-rib TR4 trapezoidal and 5-rib TR5 panel double layer roll forming machine is designed specifically for Bolivia’s expanding construction market. In one continuous process, this system produces both sturdy TR4 trapezoidal roofing sheets and attractive TR5 interlocking panels, maximizing throughput while minimizing labor and footprint.

Key benefits of double layer roll forming machine :

- – High Efficiency: Dual-profile forming cuts production time in half.

- – Space-Saving Design: Integrates two lines into one compact unit.

- – Versatile Material Range: Supports 0.3–0.8 mm PPGI, galvanized or color-coated coils.

TR4 TR5 Double Machine

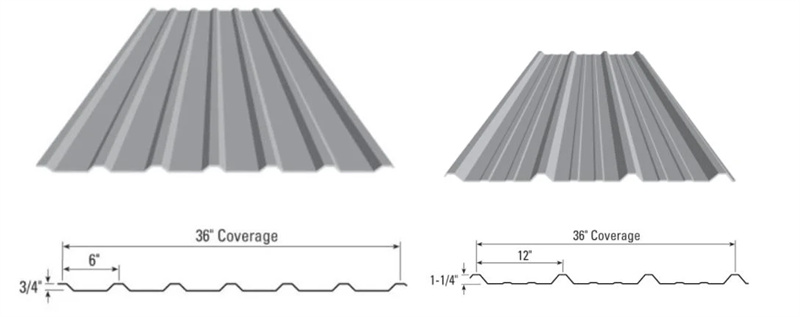

The Drawing Profile:

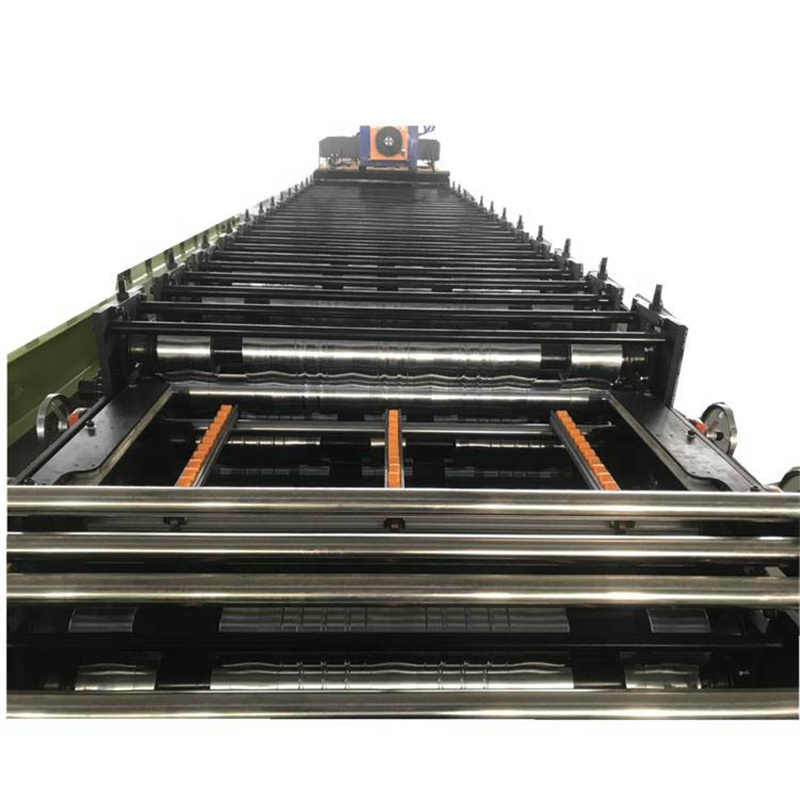

Features of TR4 and TR5 Trapezoidal Double Layer Roll Forming Machine

- Robust Construction: Heavy-duty C-shaped frame (16 mm thickness) welded and stress-relieved to prevent deformation under load.

- Precision Rollers: 45# hardened steel rollers with 0.05 mm chrome plating for corrosion resistance and long service life.

- Automatic Decoiler: Hydraulic expansion ensures stable coil feeding and quick material changeover.

- PLC & HMI Control: User touchscreen interface for one-button start, parameter adjustment, and fault diagnostics.

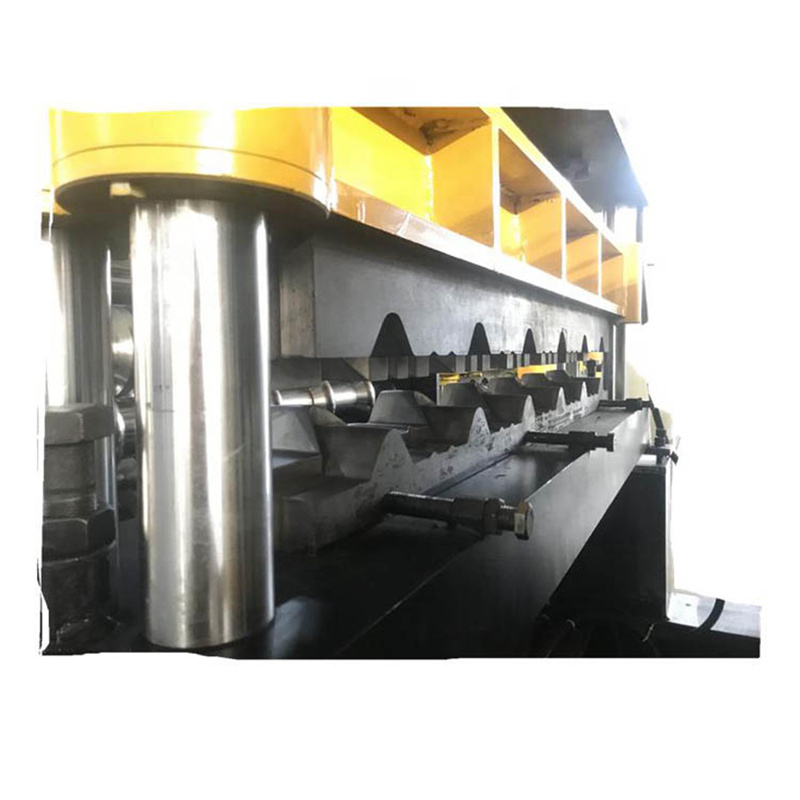

- Integrated Cutting: Hydraulic shear with Cr12MoV blades, guaranteeing ±1 mm cutting accuracy at high speeds.

Technical Specifications of TR4 and TR5 Trapezoidal Double Layer Roll Forming Machine

| Parameter | Specification |

| Material Thickness | 0.3–0.8 mm |

| Coil Width | 900–1,250 mm |

| Roll Stations | 16–18 passes |

| Shaft Diameter | 70 mm solid, chrome-plated |

| Forming Speed | 8–20 m/min |

| Main Motor Power | 11 kW |

| Hydraulic Station | 5.5 kW |

| Cutter Tolerance | ±1 mm |

| Machine Dimensions | 6.8 × 1.0 × 1.5 m |

| Total Weight | ≈ 5.5 T |

Applications of TR4 and TR5 Trapezoidal Double Layer Roll Forming Machine in Bolivia

- – Industrial Roofing: Durable TR4 trapezoidal sheets withstand heavy rainfall and UV exposure in the Altiplano.

- – Wall Cladding: TR5 panels provide seamless overlap and aesthetic appeal for commercial and residential buildings.

- – Prefabrication: Rapid production supports modular housing, mining camps, and agricultural structures.

Packaging, Delivery & After-Sales for TR4 and TR5 Trapezoidal Double Layer Roll Forming Machine

- – Delivery Time: 40–50 working days from factory.

- – Packaging: Wrapped in protective tarpaulin, secured in 20′ container.

- – Warranty: 24 months on main frame and rollers.

- – Support: Remote PLC diagnostics, on-site installation guidance, operator training, and spare parts supply.

Contact Us: Elevate your production capabilities with our TR4 and TR5 trapezoidal double layer roll forming machine. Reach out today for a tailored quotation and technical consultation!

Engineered by Zhongtuo for Precision and Surface Protection As patio and pergola structures become more

Zhongtuo Industrial Cable Tray Roll Forming Production Line Zhongtuo Cable Tray Roll Forming Machine is

Full Automatic Steel Supermarket Shelves Storage Rack Upright Pillar Roll Forming Machine Improve Warehouse Efficiency

Cable Ladder & Cable Tray Roll Forming Machine High-Efficiency Steel Side Rail Forming Machine for

STAY IN THE LOOP