Main technical parameters for the High Speed Slitting Line

|

Other parameters |

Power |

380V/50Hz/3Ph |

| Line speed |

0-30m/min(4-10mm) 0-60m/min(2-4mm)

|

|

| Capacity |

About 500 Kw |

|

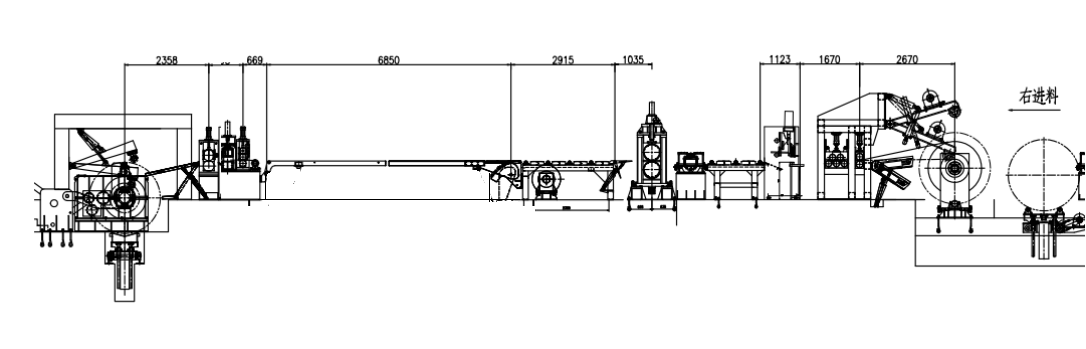

| Whole line Dimension | About 35m(L)X9m(W) | |

| Operator needed | 1 mechanical engineer,2 common workers | |

| Line direction | From right to left(Face to machine) | |

| Machine color | Blue |

2. The workflow of the Slitting Machine

From right to left are: Entry coil car→Decoiler →Press and pinch device→Cutter→ Transition table→Side guide device→ Slitter→Scrap winder→Transition table→Tension stand →Recoielr→Exit coil car

3. Brief introduction of Steel Slitting Process Explained

ZT-10X1600mm steel coil slitting line is used for slitting the hot rolled steel coils to prepare for the next process.

- V-shape base

◆It is used to load the coil, to prevent damaging the car by putting the coil into the car directly.

◆It is one pair (two pieces), length 1000mm, width 480mm.

2. Hydraulic entry coil car

◆Hydraulic coil car is composed of base, axle, wheels, bearing and guide rods, guide bushing, up-supporting seat, rolling wheel, hydraulic lifting cylinder, and hydraulic motor.

3. Double-head decoiler

◆Decoiler is a pair of taper-shaped uncoiling machines. It is composed of a linear model base, frame, decoiler shaft, taper plate, and hydraulic pushing device. One of the decoilers is equipped with a brake

Automatic slitting line

◆Parameters:

| Item | Parameters | Quantity |

| Capacity | 20T | |

| Main bearing for decoiler | 24140 | sets |

| Design model | Taper-shaped | 1 pair |

| Expand range | φ508mm—φ760mm | |

| centering cylinder | Diameter φ125mm, stroke 1100mm | 2 units |

◆When the coil car lifts the steel coils and the coil diameter center is aimed at the decoiler center. Two decoilers against the coils. The two decoilers can be centered independently, also can be centered together to load the coils. When the coil is not in the production center, the double decoiler can move together to the left or right accordingly. When uncoiling, stop the brake, and when you stop running, start the brake.

4. Press and pinch and pre-leveler device(45KW DC)

◆This is composed of a bottom-stand(frame), hydraulic pressing and guiding arm, hydraulic shovel-head device, pinch and preliminary leveling device, power device, etc.

◆Hydraulic pressing & guiding device is composed of hydraulic pressing and guiding arm, pressing and guiding wheel(covered by rubber), sprocket wheel, chain, accompanied by motor, etc.

◆Hydraulic shovel-head device is composed of the shovel-head body, the hydraulic shovel-head, balanced device for the hydraulic shovel-head.

◆Hydraulic pinch and preliminary leveling machine is composed of slide-stand, pinch roller(2pcs), hydraulic pinch device, 5pcs of pre-leveling rollers, hydraulic pre-leveling device, etc.

◆Power device for pinch is composed of a 45 kW DC speed control motor, decelerator, gear distributor case, clutch, one group spindle, etc.

| Item | Parameters | Quantity |

| press motor | 7.5Kw

Cycloid motor 7.5KW |

1 unit |

| pinch roller motor | 45KW DC | 1 unit |

| Press cylinder | Piston diameter φ160mm and stroke 770mm | 2 pcs in synchronization |

| Pinch rollers and pre-leveling rollers | Diameter:φ220mm, material 40Cr, hardness: HRC 48-52 | 2 pcs for each |

| Bearing | Model: 217 | 16sets |

◆Brief introduction: The steel coils press the arm to press down. Cut off the belts and run the press wheel by the motor to make the steel head move forward. Expand the Hydraulic shovel-head device and adjust the balance cylinder to control the height of the shovel-head. Once receiving the steel head, lift up and down the hydraulic head-leveling device to press and straighten the head to ensure the head can pass the press and pinch device smoothly. Adjust the pre-leveling roller to feed the pre-leveled sheets to the roller table.

-

Hydraulic Head Cutter

◆shear model: cut from up to down, which is coordinated with the signal directly from the encoder and shear automatically

◆Automatic control of the shearing

◆ Four-sided cutter, the material is H13K, a nd it can shear a 10mm steel plate safely after heat treatment

- Roller table

◆It is composed of a frame, rollers, a supporting plate, and a bearing seat.

Width: 1600mm, length: 1.6 m

Roller diameter: 140mm, supporting bearing 212: 8pcs

◆Brief description: The roller table is used to feed the sheets, and the roller design is to prevent the sheets from scratching the table directly and protect the sheets.

-

Side guide device

◆ The side guide device is composed of the linear model base, movable plate, adjustment device, and stand rollers.

◆Parameters

| Thickness

Name |

2~10mm |

| Adjustment width | 800~1600mm |

| stand roller quantity | 4 |

| Press roller diameter | Φ120mm |

| HRC Surface hardness | 50~54 |

| main bearings | 7212,8212:2 sets for each,314:8 Set |

◆Brief introduction: The side guide device is to guide the sheets from the pre-leveling device and centering to the slitting machine to avoid left or right deviation.

Automatic slitting line

-

Slitting machine(160KW DC)

◆ The slitting machine is one of the important parts of the whole line.

◆Power part: consists of bottom base, decelerator, 160KW DC motor, and universal coupling as well as gear distributing case, coupler, spindle, connecting cover, etc.

◆Parameters:

| Machine

Specification |

2-10mm slitting line |

| Motor model | 160KW |

| knife pivot diameter | Φ320mm |

| width | wider than the sheet |

| blade material | H13K |

| Blade specification | Φ320XΦ480x20mm |

| main bearing | 672758,8256,2 sets for each

7238,238, 2 sets for each |

| pushing cylinder | Diameter:Φ125mm,

stroke 700mm |

| pivot lifting motor | BWD13-35-3:3KW |

The ZTRFM heavy-duty coil recoiler is engineered for handling narrow-width and light-gauge strip materials, ensuring

The metal coil slitting and recoiling machine is designed for processing narrow-width strips with high

High-Precision Coil Embossing Machine for Decorative and Structural Metal Applications As a trusted coil embossing

Ridge cap Roll Former-12” universal Ridge cap Ridge Cap Roll Former – Hems both

STAY IN THE LOOP