The Galvanized Metal Stud and Track Roll Forming Machine is designed for fully automatic batch production of metal profiles used in gypsum board systems, drywall partitions, and suspended ceilings. Controlled by PLC, the machine operates at speeds of 25–80 meters per minute, delivering high efficiency and consistent quality.

| Work type | Passive type |

| Loading capacity | 1.5 Tons |

| Coil inner diameter | 450-550 mm (adjustable) |

| Quantity | 1 set |

| Details | Parameter |

| Raw material | Galvanized steel & H.R |

| Material thickness | 0.3-0.8 mm |

| Cutting length | Adjustable |

Note :

- There is hand wheel on the feeding part, easy for you adjust the feeding size when produce different sizes of products

- There is also guiding device, easy for the material go into the machine smoothly and quickly.

We use split rollers to realize one machine to produce different sizes of drywall studs, you can adjust the size automatically by PLC

Please check the yellow box, there isan oil drip device on the feeding part, which can cause oils on the products, in case the raw material is zinc off during roll forming.

Part 2&3: Leveling & roll forming system |

|

| Rolling shaft | Shaft material: 45# steel |

| Shaft diameter: 60 mm | |

| Tempering treatment | |

| Roller | Roller material: Cr12 |

| Quenched treatment | |

| Rolling station number | 15 stations |

| Work speed | 0-40 m/min(without punching) 0-30m/min(with punching) |

| Machine frame | Base uses high-quality H steel;

Vertical iron arch casting frame structure |

| Bearing | famous Chinese brand Harbin ( high quality) |

| Work power | 7.5 kw+7.5kw |

| Transmission | By Gear |

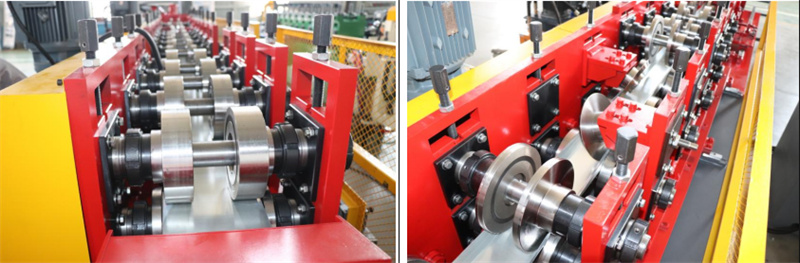

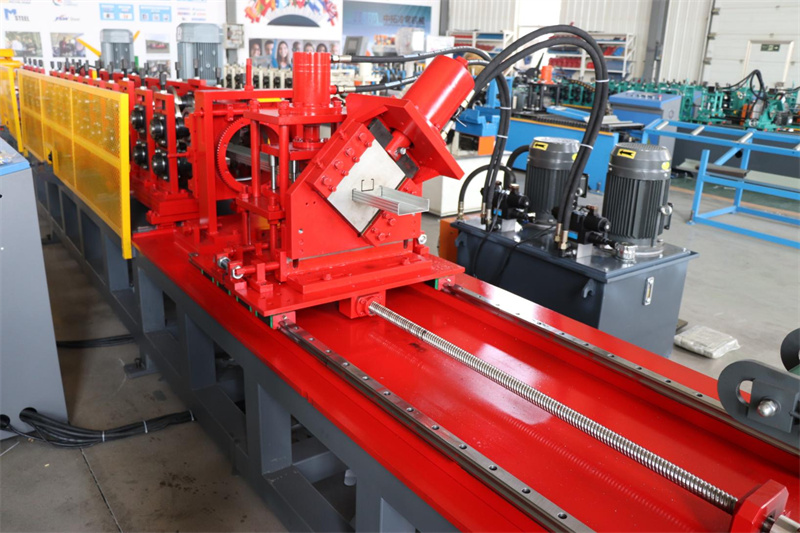

The roll forming machine pictures |

|

The Galvanized Metal Stud and Track Roll Forming Machine

Part 3: PLC control system |

|

| Frequency brand | Delta (original) |

| PLC brand | Delta (original) |

| Screen type | Touch screen & buttons |

| Screen language | English/Chinese |

| Encoder | Omron |

| Low-pressure electrical part brand | Schneider |

| Function | The computer is used to control length & quantity. The machine will automatically cut to length and stop when the required quantity is achieved. |

The Galvanized Metal Stud and Track Roll Forming Machine

Part 4: Hydraulic System |

|

| Feature | The cutter with different sizes according to the product dimension. |

| PLC brand | DELTA brand |

| Work type | Servo flying, Hydraulic cutting system |

| Servo motor power | YASKAWA 1.8KW |

| Hydraulic power | 5.5 +5.5 kw |

| Driving method | By pillar type, Cylinder |

| Cutter material | GB-Cr12 |

| Cutting length tolerance | ±1mm/3m |

| Cutting feature | Flying cutting. When the machine is cutting, it will not stop |

The ZTRFM heavy-duty coil recoiler is engineered for handling narrow-width and light-gauge strip materials, ensuring

The metal coil slitting and recoiling machine is designed for processing narrow-width strips with high

High-Precision Coil Embossing Machine for Decorative and Structural Metal Applications As a trusted coil embossing

Ridge cap Roll Former-12” universal Ridge cap Ridge Cap Roll Former – Hems both

STAY IN THE LOOP