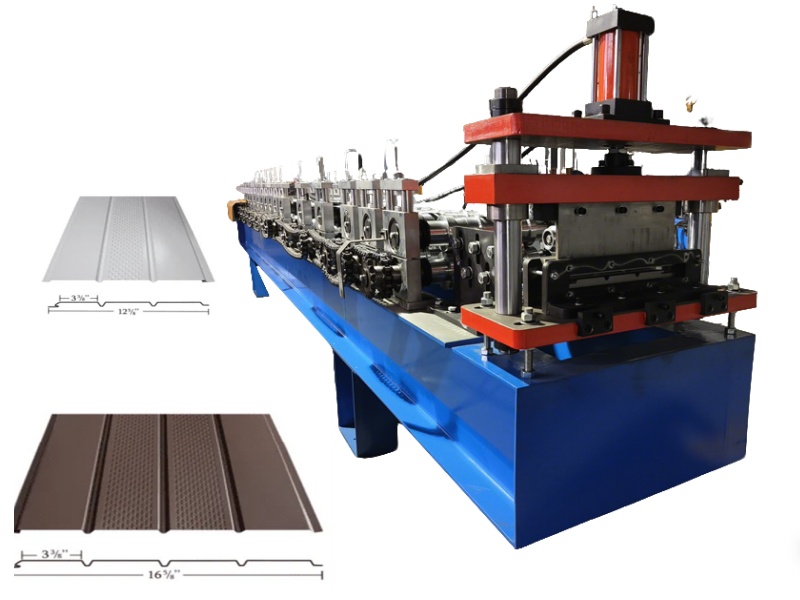

Standing Seam Roofing Sheet Forming Machine

Seeking a high-performance standing seam roof panel roll-forming machine? Our advanced Standing Seam Roll Forming Line features a 3T double-head hydraulic decoiler, a precision roll former, a PLC control system, fly shearing hydraulic cutting, and a fully automatic stacker. With this complete production line, you can achieve fast, accurate, and cost-efficient roof panel production.

Standing seam machine

This machine is designed for metal roofing manufacturers, contractors, and construction material suppliers who require customized roof panel production with superior accuracy and durability.

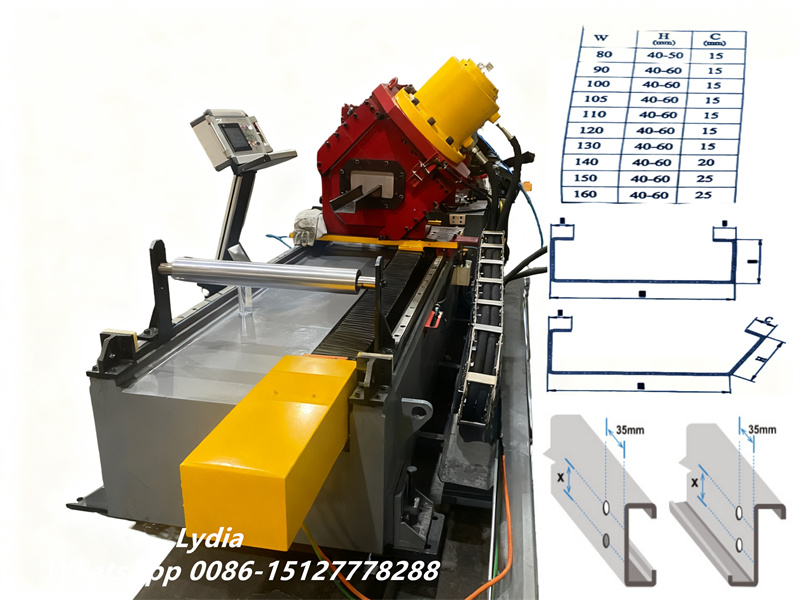

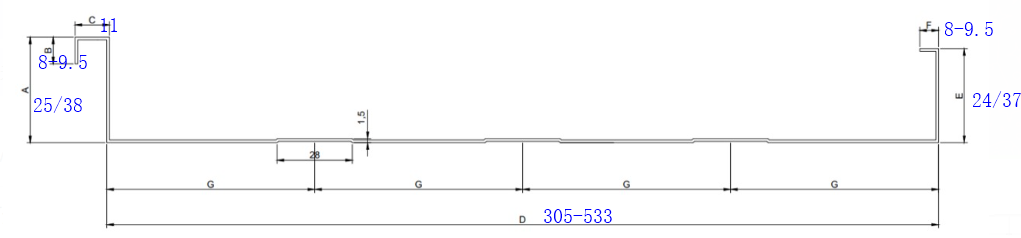

The Drawing Profile of the Standing Roll Forming Machine:

Standing seam machine

Key Advantages of the standing seam roof panel roll forming machine

- High Efficiency: Production speed 30–50 m/min, ensuring faster project delivery.

- Precision Cutting: Hydraulic fly cutting with ±1mm/3m tolerance.

- Stable Decoiling: 3T double-head hydraulic decoiler with loading car for continuous operation.

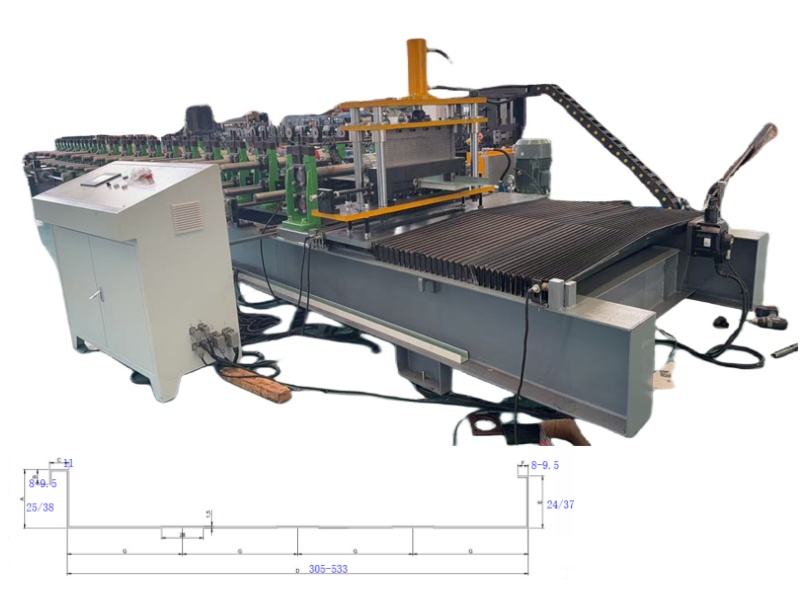

Standing seam machine

- Strong Structure: Cast iron frame and H-beam welded base with anti-rust treatment.

- Smart Control: Delta PLC + multi-language touch screen (English, Chinese, Spanish).

- Custom Profiles: Adjustable effective width and cutting length according to project needs.

- Durability: Rollers made from GCr15 with quenching treatment, long-lasting performance.

- Global Standards: Equipped with Schneider, Delta, and Omron components for reliable performance.

Standing seam machine

Technical Parameters of Standing Seam Roof Sheet Roll Forming Machine

| Series | Details | Parameter |

|---|---|---|

| Product Sheet | Raw Material | Aluminum, PPGI |

| Material Thickness | 0.35–0.6 mm | |

| Effective Width | As request | |

| Sheet Cutting Length | Adjustable | |

| Decoiler | Type | 3T Double Head Hydraulic with Loading Car |

| Core Inner Diameter | 450–550 mm | |

| Max Coil Width | 610 mm | |

| Carrying Capacity | 3T + 3T | |

| Main Roll Former | Rolling Stations | 18 stations |

| Shaft Diameter | 70 mm (solid, 45# steel, tempered) | |

| Roller Material | GCr15, quenched | |

| Speed | 30–50 m/min | |

| Motor Power | 18.5 kw servo | |

| PLC System | Brand | Delta PLC + Touch Screen |

| Functions | Cut command, length setup, batch program | |

| Encoder | Omron | |

| Electrical Parts | Schneider | |

| Cutting System | Type | Hydraulic Fly Cutting |

| Tolerance | ±1mm/3m | |

| Cutter Material | GB-Cr12 | |

| Receiving Table | Length | 3 meters |

| Width | 1.25 meters |

Optimize Your Roofing Production with ZTRFM

Our Standing Seam Roof Panel Roll Forming Machine is the ultimate solution for producing customized, durable, and high-quality roofing sheets. With hydraulic decoiling, high-speed roll forming, and automatic stacking, this production line ensures efficiency, safety, and precision for global construction projects.

Standing seam machine

Standing seam machine

Whether you are in roof panel manufacturing, building construction, or metal sheet distribution, this machine delivers outstanding results and long-term reliability.

Stainless Steel & Aluminum Door Frame Making Machine The stainless steel and aluminum door frame

The ZTRFM Soffit Panel Roll Forming Machine is engineered for manufacturers who require fast, stable,

Cee & Zee Eave Struts Roll Forming Machine for Metal Buildings High-Performance Purlin Mill In

We are pleased to announce the successful delivery of our high-performance double-layer trapezoidal RIB metal

STAY IN THE LOOP