Slotted Angle Roll Forming Machine for Light and Heavy Duty Production

The Slotted Angle Roll Forming Machine is a fully automatic solution built for producing both light-duty and heavy-duty slotted angles. It supports the efficient creation of metal framing components used in shelving, workstations, safety guards, and more. Made from 12 or 14-gauge roll-formed steel, these angles feature pre-designed holes for easy bolted assembly.

Benefits of Slotted Angle Profiles Made by the Slotted Angle Roll Forming Machine

– Easy to assemble with no need for drilling or welding

– Precision slotted pattern allows for multi-angle connections

– Available in various lengths such as 96 inches, 120 inches, and 144 inches

– Reusable for rebuilding or expanding existing structures

– 14-gauge is suitable for standard tasks, and 12-gauge is ideal for heavy-duty loads

Punching Options for the Slotted Angle Roll Forming Machine

To meet different production needs, the Slotted Angle Roll Forming Machine offers two punching methods:

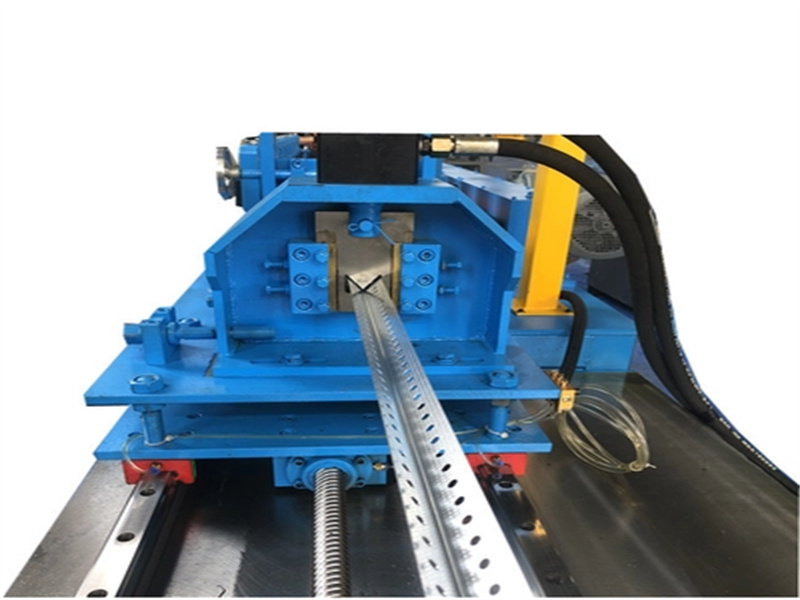

CNC Punching System

– Recommended for complex hole patterns

– Processing speed of around 15 to 20 meters per minute

Rotary Punching System

– Suitable for high-speed applications with simpler hole designs

– Runs at 50 to 80 meters per minute

– Note: Some profiles with intricate holes may only be supported by CNC punching

Slotted Angle Roll Forming Machine

Technical Details of Rotary Punching for the Slotted Angle Roll Forming Machine

| Feature | Specification |

| Material Width | 70 mm |

| Thickness Range | 1.0 to 1.2 mm |

| Punch Tool Material | DC53 hardened to HRC 61 to 63 |

| Shaft Material | Heat-treated 45Cr steel, 150 mm diameter |

| Motor Power | 15 kW |

| Control System | PLC |

| Production Speed | Up to 60 meters per minute |

Roll Forming Specifications of the Slotted Angle Roll Forming Machine

| Feature | Specification |

| Material Width | 70 mm |

| Thickness Range | 1.0 to 1.2 mm |

| Punch Tool Material | DC53 hardened to HRC 61 to 63 |

| Shaft Material | Heat-treated 45Cr steel 150 mm diameter |

| Motor Power | 15 kW |

| Control System | PLC |

| Production Speed | Up to 60 meters per minute |

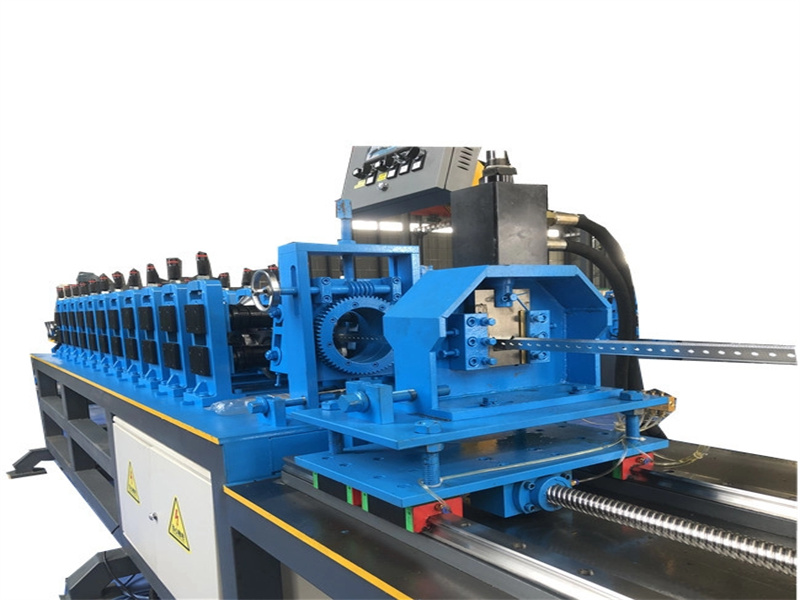

Appearance and Structure of the Slotted Angle Roll Forming Machine

The Slotted Angle Roll Forming Machine features a clean surface finish with no burrs rust or paint defects. All cables are organized properly and the machine body is painted using automotive-grade methods for enhanced durability and aesthetics.

Usage Note for the Slotted Angle Roll Forming Machine

Please be aware that some complex hole configurations cannot be processed by the rotary punching system. In such cases the CNC punching system is required and fully supported by our Slotted Angle Roll Forming Machine range.

Stainless Steel & Aluminum Door Frame Making Machine The stainless steel and aluminum door frame

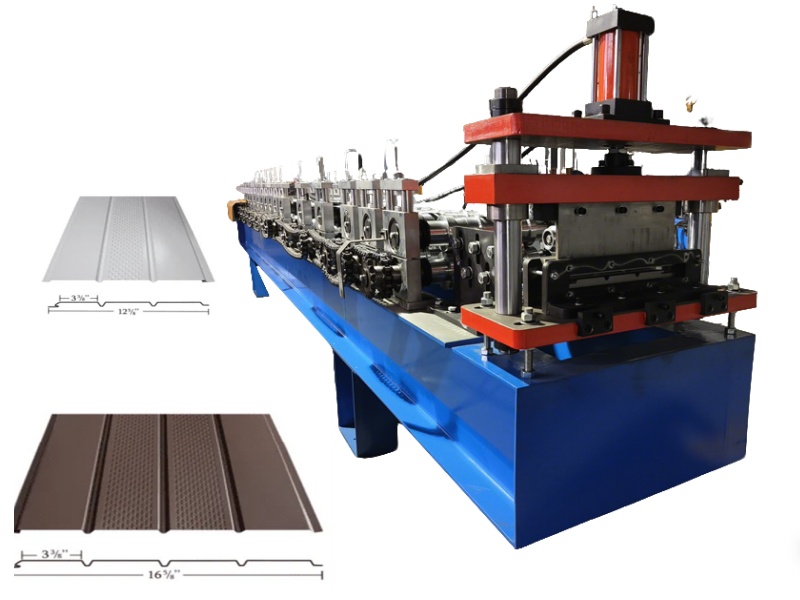

The ZTRFM Soffit Panel Roll Forming Machine is engineered for manufacturers who require fast, stable,

Cee & Zee Eave Struts Roll Forming Machine for Metal Buildings High-Performance Purlin Mill In

We are pleased to announce the successful delivery of our high-performance double-layer trapezoidal RIB metal

STAY IN THE LOOP