Lift Table Method for Roll Forming Machine Stacking Systems

In modern roll forming production lines, efficiency and safety are always top priorities. To achieve smooth stacking of finished metal sheets or profiles, a hydraulic lift table is often integrated with the automatic servo stacking system. This auxiliary equipment not only reduces manual handling but also ensures that heavy steel sheets can be stacked neatly and transported easily.

hydraulic lift table

Enhanced Safety and Stability

First of all, safety is one of the most important aspects when using a lift table in roll forming production. The platform is equipped with a robust hydraulic system that prevents sudden drops. In addition, safety sensors and emergency stop switches are commonly included, ensuring that both the operator and the materials are fully protected during operation. With these features, the stacking process becomes more reliable and secure.

Technical Specifications of Triple Scissor Lift Table

To better understand the performance of our lift table designed for roll forming machine stacking, the following technical details can be referenced. This specification table provides clear information on model, size, lifting range, and other essential parameters:

| Item | Specification |

|---|---|

| Model | DGH1000 Triple Hydraulic Scissor Lift |

| Table Size | 1700 × 1000 mm |

| Lifting Height | 470 – 3000 mm |

| Load Capacity | 1 ton |

| Voltage Requirement | 208V, 60Hz (customized motor) |

| Delivery Time | 15 days |

| Packaging | Strong wooden box for safe international shipping |

| Trade Terms | CIF Newark |

| Technology | Powder-spraying technology for a durable and aesthetic finish |

As shown in the table above, this lift table is designed with durability, high load-bearing capacity, and fast delivery in mind. The customized motor and protective wooden packaging also guarantee safe international transportation and smooth installation.

Triple Scissor Lift Table

Smooth and Controlled Lifting

Moreover, the hydraulic lift table provides stable and precise lifting for sheet metal stacking. The lifting speed can be adjusted according to the thickness, weight, and size of the formed panels. Thanks to its powerful pump station and reinforced scissor arms, the table can carry heavy loads without vibration or tilting. As a result, sheets are stacked evenly, which helps improve the overall quality of the final package

Triple Scissor Lift Table

Triple Scissor Lift Table Improves Work Efficiency

In addition, combining a roll forming machine with a lift table significantly improves production efficiency. Workers no longer need to bend or lift heavy metal sheets manually. Instead, the finished sheets are automatically stacked on the lift platform, which can then be lowered or raised to the appropriate height. This automation reduces physical labor, minimizes downtime, and increases throughput for large-scale production.

lift table for roll forming machine stacking

To sum up, the lift table for roll forming machine stacking is not just an accessory but an essential part of a modern roll forming production line. With advantages such as safety, stability, efficiency, durability, and flexibility, it greatly enhances the performance of stacking systems. Therefore, whether you are producing roofing sheets, wall panels, or structural profiles, adding a hydraulic lift table will optimize your workflow and maximize your output

SEO Keywords Embedded: roll forming machine lift table, hydraulic lift table, stacking system, metal sheet stacking, servo stacking lift, scissor lift for roll forming, sheet metal lift table, roll forming auxiliary equipment

Stainless Steel & Aluminum Door Frame Making Machine The stainless steel and aluminum door frame

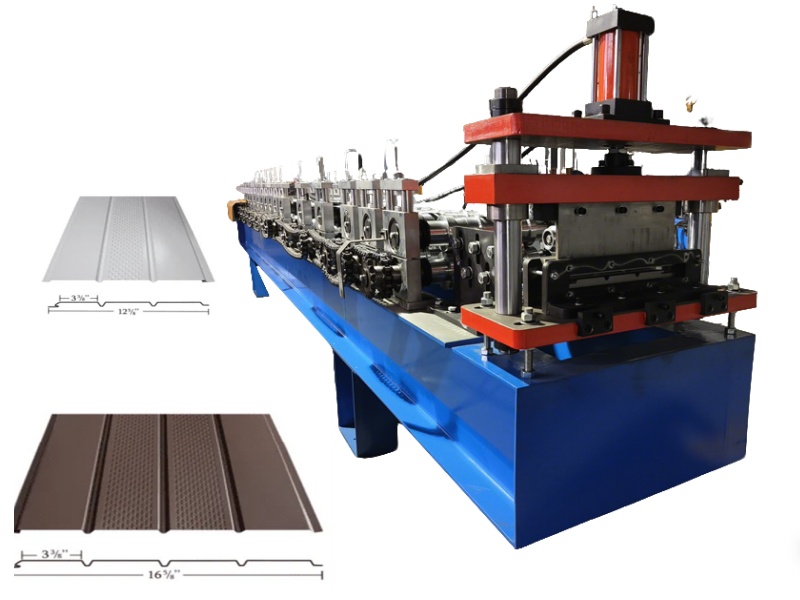

The ZTRFM Soffit Panel Roll Forming Machine is engineered for manufacturers who require fast, stable,

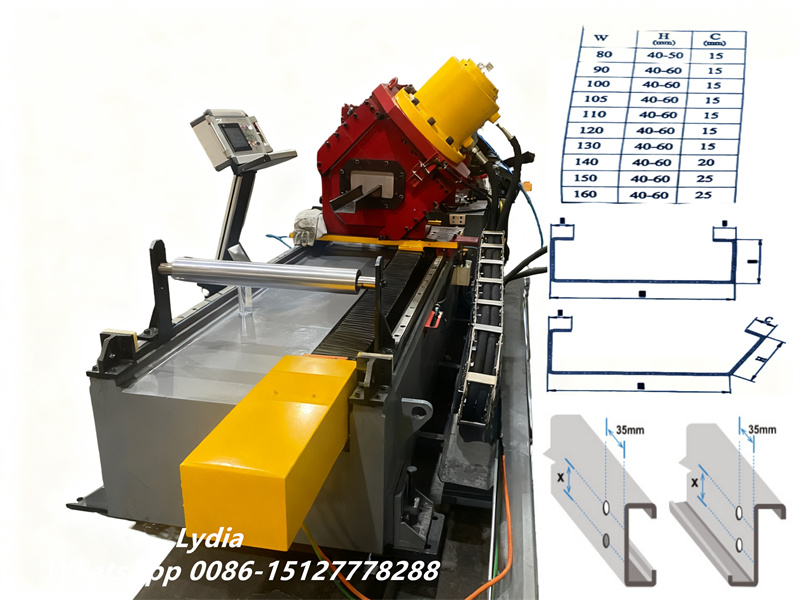

Cee & Zee Eave Struts Roll Forming Machine for Metal Buildings High-Performance Purlin Mill In

We are pleased to announce the successful delivery of our high-performance double-layer trapezoidal RIB metal

STAY IN THE LOOP