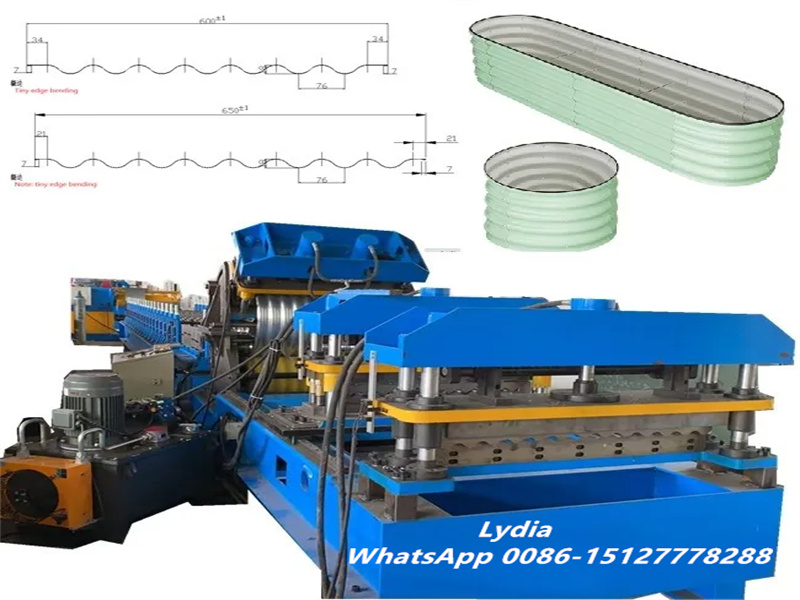

Overview of Corrugated Metal Garden Bed Roll Forming Machine

This equipment is specially engineered to manufacture corrugated panels designed for metal raised garden beds. These beds are ideal for gardens, rooftops, and patios, offering a combination of durability, resistance to decay, and weed control. Crafted from galvanized steel, the beds promote excellent drainage, support deep root systems, and boast a lifespan that resists rust and mildew.

Key Features of Corrugated Metal Garden Bed Roll Forming Machine

- Primary Components:

The production line includes a decoiler, a forming section, a cutting unit, and a PLC-controlled automation system, all integrated for efficient and precise operation.

- Operational Efficiency:

Built for high-speed output, this machine reduces downtime and waste, delivering reliable and efficient production.

- Customizability:

Its quick-change tooling system ensures that different panel designs can be accommodated. This machine is also suitable for shaping rounded galvanized steel panels, enhancing corrosion resistance and durability.

Applications of Metal Raised Bed Roll Forming Machine

Corrugated or rounded raised garden bed panels,

Lightweight yet sturdy garden bed components,

Products that resist corrosion, wear, and environmental degradation.

| Parameter | Specification |

| Pressing thickness | 0.35MM, galvanized sheet 235-350MPa |

| Effective width | 287mm |

| Feed width | As Request |

| Hydraulic station motor | 5.5KW |

| Transmission motor | 7.5KW |

| Roller shaft diameter | 70mm |

| Spindle material | 45# steel |

| Side panel thickness | 22mm, integrated side panel |

| Machine base specification | 400H steel + 14MM sealing plate, rear gantry milling, flat surface |

| Forming passes | 20 sets |

| Roller material | 45# steel, precision-machined, brushed, and polished |

Engineered by Zhongtuo for Precision and Surface Protection As patio and pergola structures become more

Zhongtuo Industrial Cable Tray Roll Forming Production Line Zhongtuo Cable Tray Roll Forming Machine is

Full Automatic Steel Supermarket Shelves Storage Rack Upright Pillar Roll Forming Machine Improve Warehouse Efficiency

Cable Ladder & Cable Tray Roll Forming Machine High-Efficiency Steel Side Rail Forming Machine for

STAY IN THE LOOP