Photovoltaic Roofing Sheet Roll Forming Machine — Built for Solar Roofs

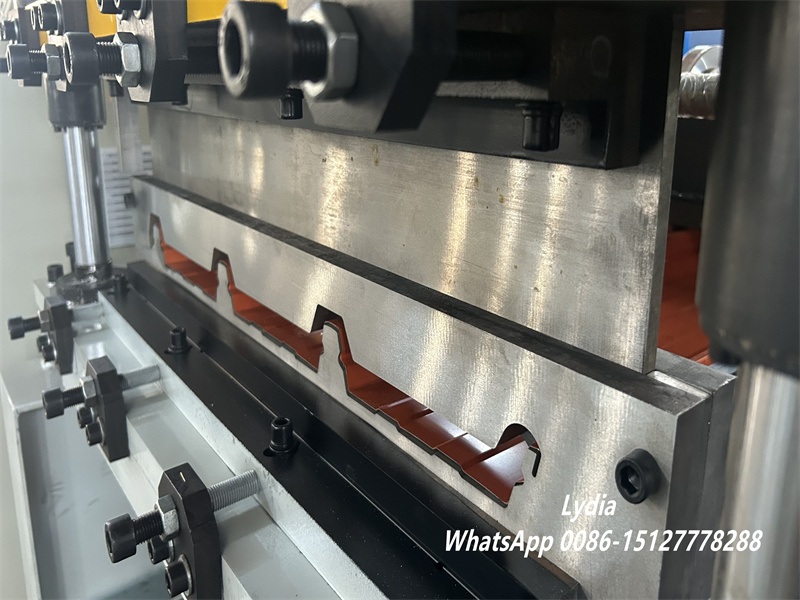

This photovoltaic roofing sheet roll forming machine is specially designed to make solar roof panels, the kind you often see supporting solar panels on industrial buildings and residential homes. Unlike the traditional curved roofing sheets, the PV roofing panels have a clean, trapezoidal shape — it look sharp, neat, and most importantly, it’s strong. That shape gives the metal more strength, helping your roof handle heavy solar modules and harsh weather.

Photovoltaic Roofing Sheet Roll Forming Machine

The machine can process steel coils that are around 914 to 1450 mm wide and 0.3 to 0.8 mm thick, perfect for making roofing sheets for solar energy systems

Technical Specifications Parameter

Material Thickness 0.4-0.6mm (0.5mm standard)

Coil Width 914mm (700mm effective)

Line Speed 25-30m/min

Power Consumption 18.5kW (with energy recovery system)

Machine Dimensions 11.5m(L) × 1.6m(W) × 1.6m(H)

Why choose this photovoltaic roofing sheet machine? First, it’s designed with a modular forming system, meaning the sheet gets shaped step by step instead of all at once. Pre-bending, folding the edges, and fine-tuning the profile — each part handles a specific task. That makes it much easier to adjust when you switch to a different sheet size or material thickness. And if one part needs maintenance, you don’t have to stop the whole machine. Plus, before the steel even gets shaped, a film laminator applies a protective film to keep the color coating clean and scratch-free during production and shipping. The pressure and tension are carefully controlled, so the film sticks perfectly without bubbles or wrinkles.

Photovoltaic Roofing Sheet Roll Forming Machine

This machine is also built for speed and stability. It uses a strong gantry frame, bolted together to minimize vibration even when running at 25 to 40 meters per minute. That keeps your panels straighter and smoother. And thanks to a smart servo shear system, it cuts the sheets on the fly — no need to stop the machine. The cutter follows the moving steel, slicing with precision and saving you time and energy. It’s a smart setup that boosts your production efficiency and helps you deliver perfect panels every time.

What You’ll Get

The roofing sheets from this machine aren’t just strong — they also look great. The shape is sharp, the dimensions are accurate, and the protective film keeps them clean until they’re installed on the roof. Whether for factories, warehouses, or solar energy projects, these panels are built to last and easy to install.

Photovoltaic Roofing Sheet Roll Forming Machine

Photovoltaic Roofing Sheet Roll Forming Machine

Photovoltaic Roofing Sheet Roll Forming Machine

The ZTRFM heavy-duty coil recoiler is engineered for handling narrow-width and light-gauge strip materials, ensuring

The metal coil slitting and recoiling machine is designed for processing narrow-width strips with high

High-Precision Coil Embossing Machine for Decorative and Structural Metal Applications As a trusted coil embossing

Ridge cap Roll Former-12” universal Ridge cap Ridge Cap Roll Former – Hems both

STAY IN THE LOOP