Introducing the New Wall Cladding Roll Forming Machine

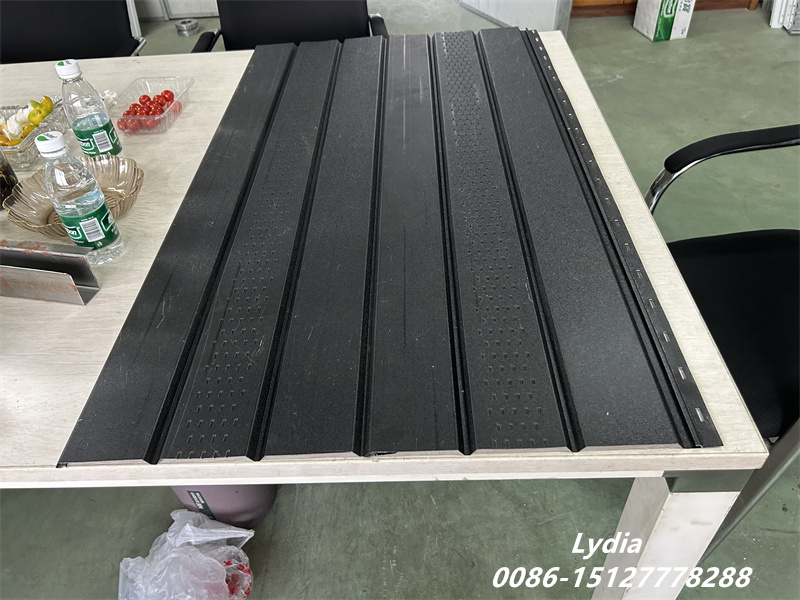

Our latest Wall Cladding Roll Forming Machine is engineered to meet the evolving demands of modern construction. Designed for efficiency and precision, this machine transforms flat metal coils into high-quality wall cladding panels, suitable for a variety of architectural applications.

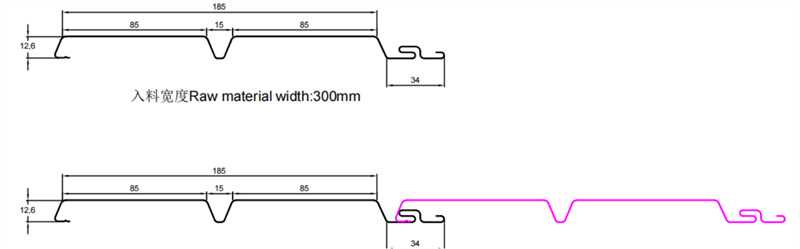

The Drawing Profile:

Key Features of the New Wall Cladding Roll Forming Machine

Advanced Control System: Equipped with a user-friendly PLC control system, featuring a touch screen interface for easy operation. The system allows for programmable settings, enabling the production of panels to specific lengths and quantities.

High-Quality Forming Rolls: The machine utilizes 18 forming stations, with rollers made from 45# steel and treated with hard chrome plating to ensure durability and precision in panel shaping.

Robust Frame Construction: Built with a welded steel frame, the machine offers stability and longevity, capable of withstanding the rigors of continuous operation.

Efficient Cutting Mechanism: Features a hydraulic cutting system that delivers clean cuts without material distortion, enhancing the overall quality of the finished panels.

Safety and Compliance: Designed with safety in mind, the machine includes protective covers and complies with international safety standards to ensure operator protection.

Material Compatibility: Suitable for processing materials such as galvanized steel and pre-painted steel, with a thickness range of 0.3 to 0.8 mm, accommodating various cladding requirements.

Technical Specifications of New Wall Cladding Roll Forming Machine

| Specification | Details |

| Forming Stations | 18 |

| Roller Material | 45# Steel with Hard Chrome |

| Shaft Diameter | 80 mm |

| Shaft Material | 45# Steel |

| Transmission | Gearbox |

| Motor Power | 5.5 kW |

| Frame Construction | Welded Steel |

| Cutting Type | Hydraulic |

| Cutting Blade Material | Cr12 High Grade Steel |

| Cutting Tolerance | ±1 mm |

| Control System | PLC with Touch Screen |

New Wall Cladding Roll Forming Machine

New Wall Cladding Roll Forming Machine

Additional Features and applications of wall cladding Forming Machine

Customizable Panel Profiles: The machine can be tailored to produce various wall cladding profiles, meeting specific design requirements.

High Production Efficiency: With a forming speed of up to 25 meters per minute, the machine ensures high throughput, optimizing production time.

Minimal Maintenance: Designed for low maintenance, the machine’s components are built to last, reducing downtime and operational costs.

Ideal for producing wall cladding panels for commercial buildings, industrial facilities, and residential projects, this machine offers versatility and reliability in panel production.

The new Wall Cladding Roll Forming Machine combines advanced technology with robust construction to deliver high-quality wall cladding panels efficiently. Its customizable features and user-friendly operation make it a valuable asset for manufacturers seeking to enhance their production capabilities.

The ZTRFM heavy-duty coil recoiler is engineered for handling narrow-width and light-gauge strip materials, ensuring

The metal coil slitting and recoiling machine is designed for processing narrow-width strips with high

High-Precision Coil Embossing Machine for Decorative and Structural Metal Applications As a trusted coil embossing

Ridge cap Roll Former-12” universal Ridge cap Ridge Cap Roll Former – Hems both

STAY IN THE LOOP