Highway Guardrail Roll Forming Machine

The highway guardrail roll forming system can be configured to produce both two-wave and three-wave profiles within a single machine setup. This flexibility is achieved by integrating additional roller stations toward the rear of the forming line.

The finished guardrail profiles are widely applied along both sides of highways, serving as critical safety barriers for vehicles.

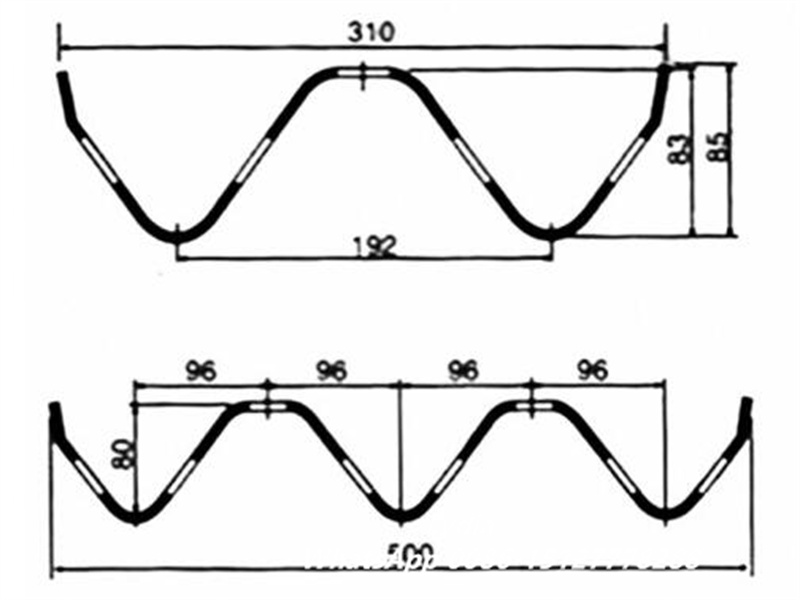

1. Customer profile drawing of Highway Guardrail Roll Forming Machine

1. Material thickness:.2.5-4.5mm

2. One machine can produce both 2 waves (W) and 3 waves (Tri) by making a little adjustment of the rollers.

2. Process flow of Highway Guardrail Roll Forming Machine

Decoiling→Feeding & leveling→Punching holes & cutting→Roll forming→Run-out table

3. Technical aspects of the whole line

10 tons hydraulic decoiler

1.Capacity:10 tons

2. Coil diameter: 450- 550 mm adjustable

3. Coil width: max 800mm

4. Hydraulic power: 4 kW

5. Motor power: 7.5 kW

| Guiding & leveling device | 1. Placed on the machine by the seller

2. Leveling rollerr:9pcs, add 2 pairs of feeding rollers 3. Roller diameter:95mm 4.Material:45# steel 5. Drive power: 5.5 kW 6.It can be the conveyor and the leveling rolls greatly improve the flatness of the panel, and the space between the rolls can be adjusted according to the different panel thickness. |

Highway Guardrail Roll Forming Machine

| Hydraulic pre-punching and cutting device | 1. Type: Hydraulic

2. Punch mode: Four-pillar hydraulic-powered punching system 3. Motor power: 18.5 kW 4.Punching mold material:Cr12 Mov with quenched treatment,hardness HRC58-60° 5.Blade material:Gcr12 Mov with quenched treatment,hardness HRC58-60° |

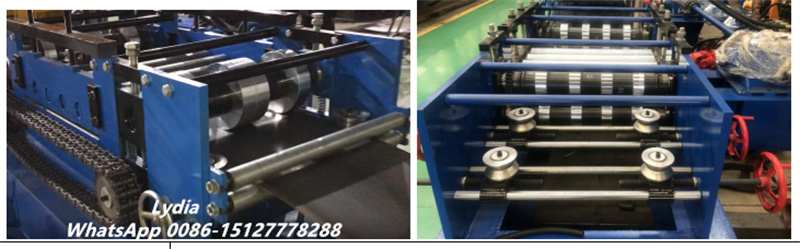

| Main forming machine

|

1.Rolling shaft material:45# steel with quenched treatment

2. Shaft diameter: 100 mm 3. Roller material: GB-Cr15 with heat treatment 4. Rolling station: 19 stations 5. Working speed: 6- 10 m/min 6. Machine frame: Iron cast vertical structure 7.Machine body:400# H steel welded 8. Bearing: famous Chinese brand HRB 9. Work power: 30 kW 10. Transmission: By gearbox 11. Appearance: Good appearance with no burrs in steel body nor traces of rust or defects in painting. |

Highway Guardrail Roll Forming Machine

This system mainly consists of a PLC, a frequency converter, and an operation platform; all the electronics adopt the famous brand, which can guarantee the quality and lifetime .And there is a breakdown protect device,ad if there is any fault of the control switch, the whole production line will stop working automatically.

The ZTRFM heavy-duty coil recoiler is engineered for handling narrow-width and light-gauge strip materials, ensuring

The metal coil slitting and recoiling machine is designed for processing narrow-width strips with high

High-Precision Coil Embossing Machine for Decorative and Structural Metal Applications As a trusted coil embossing

Ridge cap Roll Former-12” universal Ridge cap Ridge Cap Roll Former – Hems both

STAY IN THE LOOP