Multi-Size Adjustable C U Stud & Track Machines play a vital role in the construction industry by producing lightweight, high-strength metal framing components. These frames are commonly used in suspended ceiling systems, partition walls, and various other structural applications. The machines utilize a roll forming process to transform flat metal strips into customized shapes and sizes.

The fully automatic high-speed C and U keel roll forming machine is engineered for interchangeable production of stud and track profiles. It delivers visually appealing, smooth-profiled products suitable for a wide range of construction environments such as hotels, factories, villas, resorts, exhibition halls, and even historical architecture restorations.

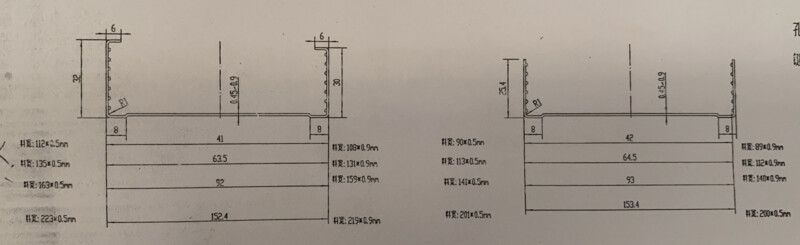

stud and track purlin machine

2. Working Process:

The machine workflow consists of:

Decoiling → Sheet guiding → Roll forming → Length measuring → Precision cutting → Finished product collection.

3. Key Advantages of C/U Stud and Track Roll Forming Machine:

This European-standard light steel roll forming system comes with a 3-ton manual decoiler, main roll forming unit, hydraulic cutting system, PLC control cabinet, and an output table.

The included manual decoiler supports coils up to 3 tons and typically requires a 3-meter space between itself and the main forming unit.

The feeding table is equipped with a roller row for flattening the strip before it enters the roll forming section. The main roll forming system is designed to manufacture various light keel sizes based on specific customer requirements.

| No. | Item | Specification |

| 1 | Suitable Material | PPGI / Aluminium Sheet / Galvanized Sheet / Various Sheet Plates |

| 2 | Coil Sheet Thickness | 0.3–0.8 mm |

| 3 | Coil Width | As per customer’s profile drawing |

| 4 | Effective Width | As per customer’s profile drawing |

| 5 | Main Frame Material | Welded by 6 mm steel plate |

| 6 | Shaft Diameter | 40 mm, High grade 45# steel |

| 7 | Roller Material | Cr12 |

| 8 | Middle Plate Thickness | Memorial archway structure |

| 9 | Forming Stations | 12 rows |

| 10 | Drive Type | Gear drive |

| 11 | Main Motor Power | 5.5 kW, Lichao (Shanghai) with reducer |

| 12 | Forming Speed | Approx. 25–30 m/min |

| 13 | Hydraulic Pump Station | 5.5 kW, 40# hydraulic oil |

| 14 | PLC | DELTA (Taiwan) / Mitsubishi |

| 15 | Cutting Blade Material | Cr12, Quenched (58–62°C hardness) |

| 16 | Frequency Converter Feature | Slows down before cutting to ensure ±1 mm accuracy (better than ±3 mm standard) |

| 17 | Switch | CHNT |

| 18 | Frequency Converter Brand | Delta, Taiwan |

stud and track purlin machine

stud and track purlin machine

stud and track purlin machine

The ZTRFM heavy-duty coil recoiler is engineered for handling narrow-width and light-gauge strip materials, ensuring

The metal coil slitting and recoiling machine is designed for processing narrow-width strips with high

High-Precision Coil Embossing Machine for Decorative and Structural Metal Applications As a trusted coil embossing

Ridge cap Roll Former-12” universal Ridge cap Ridge Cap Roll Former – Hems both

STAY IN THE LOOP