Description of Deep Track Roll Forming Machine

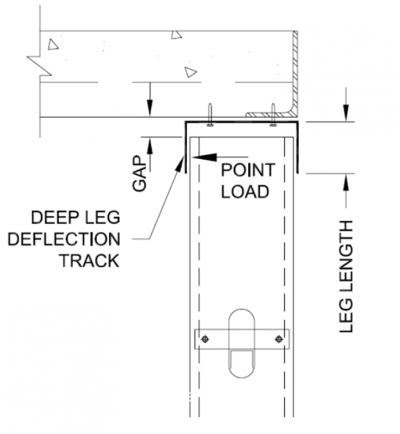

This conventional assembly is designed to accommodate building structure deflection at the head of the wall.

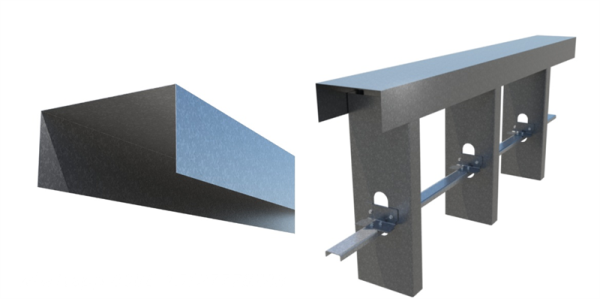

ZTFRM Deep tracks are offered in sizes of 1 5/8″, 2 1/2″, 3 5/8″, 6”, 8”, 10”, 12”, and 14”, with leg size 2”, 2-1/2”, 3” custom leg size and lengths are available too to suit your specific.

The single long leg track assembly utilizes 1-1/2″ cold-rolled channel along with 1-1/2″ x 1-1/2″ 16-gauge EasyClip Clip Angles (U-Series) or another bridging method, installed continuously at the uppermost punch-outs to ensure vertical alignment of the studs within the wall plane. It is essential that deflection track details are tailored to the specific conditions of a building, allowing for necessary deflection and end reactions from the studs. Note that deflection tracks are not suitable for use in axial load-bearing stud applications or above continuous window spandrels.

Deep Track Roll Forming Machine Specification

- Nonproprietary system

- Traditional framing components.

- Requires bridging at top of wall.

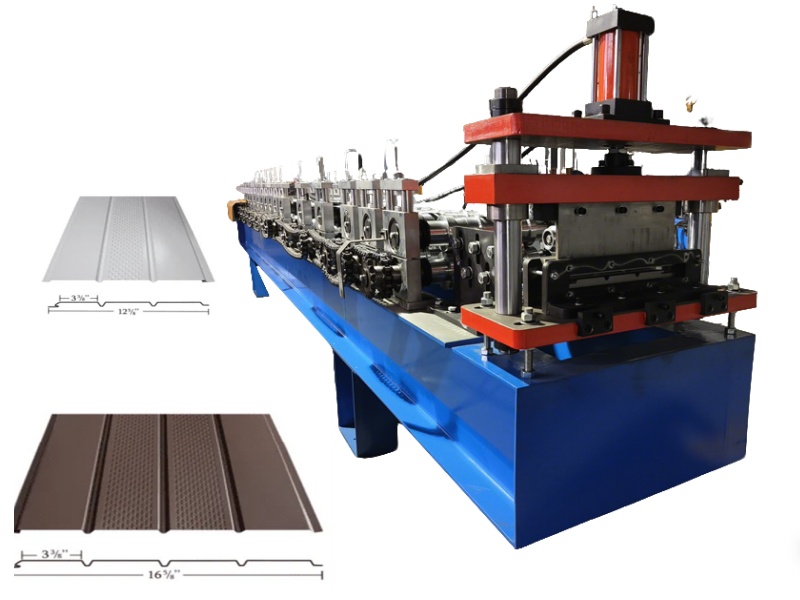

Profile Drawing:

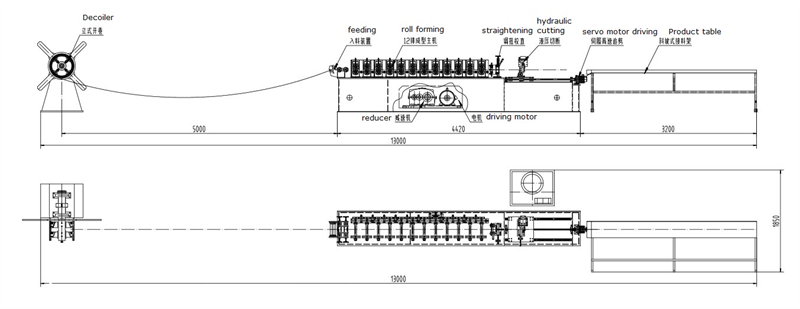

Deep Track Roll Forming Machine working flow:

The Technical Specifications Of The Deep Track Roll Forming Machine Rolling Forming Machine:

|

Deep Track rolling forming machine |

||

| 1.Formed Material | GI | Thickness: 0.4-0.6 mm |

| 2.Decoiler | Hydraulic automatic decoiler | Manual decoiler(will give you as free) |

| 3.Main body | Roller station | 12rows(As your requirement) |

| Diameter of shaft | 45mm solid shaft | |

| Material of rollers | 45# steel, hard chrome plated on the surface | |

| Machine body frame | Metal steel welded | |

| Drive | Gearbox transmission | |

| Dimension(L*W*H) | 5500*800*1200(customize) | |

| Weight | About 3T | |

| 4.Cutter | Automatic | cr12mov material, no scratches, no deformation |

| 5.Power | Motor Power | 7.5KW |

| Hydraulic system power | 5.5KW | |

| 6.Voltage | 380V 50Hz 3Phase | As your requirement |

| 7.Control system | Electric Box | Customized(famous brand) |

| Language | English(Support multiple languages) | |

| PLC | Automatic production of the whole machine. Can set batch, length, quantity, etc. | |

| 18.Forming Speed | 0-50 m/min(customized) | Speed is adjustable according to customer’s request |

More pictures of the machine:

Container house frame making machine Australian specification standards shipping living container house frame making machine is

Specification Standards Shipping Living Container House Frame Making Machine The Australian specification standards shipping living

Stainless Steel & Aluminum Door Frame Making Machine The stainless steel and aluminum door frame

The ZTRFM Soffit Panel Roll Forming Machine is engineered for manufacturers who require fast, stable,

STAY IN THE LOOP