Corner Beads Roll Forming Machine for Drywall & Construction Profile

In drywall finishing and construction work, metal corner beads, also known as angle beads, play a vital role. They strengthen edges, create neat lines, and protect corners from damage. A corner bead roll forming machine is designed to manufacture these profiles automatically, ensuring consistent results with higher speed and lower costs compared to manual methods.

For builders and manufacturers seeking to enhance production while maintaining top quality, this equipment is an excellent choice.

angle bead roll forming machine

Key Technical Parameters of Corner Beads Roll Forming Machine

When selecting a corner bead forming machine, manufacturers usually consider:

-

Material range: Galvanized steel, thickness approx. 0.2–0.8 mm.

-

Common profile size: 30×30 mm, though customization is available.

-

Production speed: About 0–25 m/min (without punching), and 0–15 m/min (with punching).

-

Cutting accuracy: Typically within ±1 mm per 3 m length.

-

Total power: Around 7.5 kW for motors, hydraulics, and control systems.

What Is a Corner Beads Roll Forming Machine?

This type of machine processes galvanized steel coils into precise corner bead profiles. The material is uncoiled, optionally punched, shaped through multiple forming rollers, and cut to exact lengths. The finished bead is widely applied in drywall systems, suspended ceilings, and plasterboard installations.

angle bead roll forming machine

Main Components & Functions of Corner Bead Profiles

A standard corner bead roll-forming line includes several important parts:

-

Decoiler / Uncoiler – Holds and unwinds the steel coil smoothly. The adjustable inner diameter and sufficient load capacity (e.g., 1.5T) enable compatibility with various coil sizes.

-

Roll Forming Section – Hardened rollers and heat-treated shafts gradually shape the steel into the required profile. With punching, production speed is slower; without it, speed increases.

-

PLC Control System – Touchscreen interface and reliable electronics (brands like Delta, Omron, Schneider) provide accurate cutting length, batch counting, and speed regulation.

-

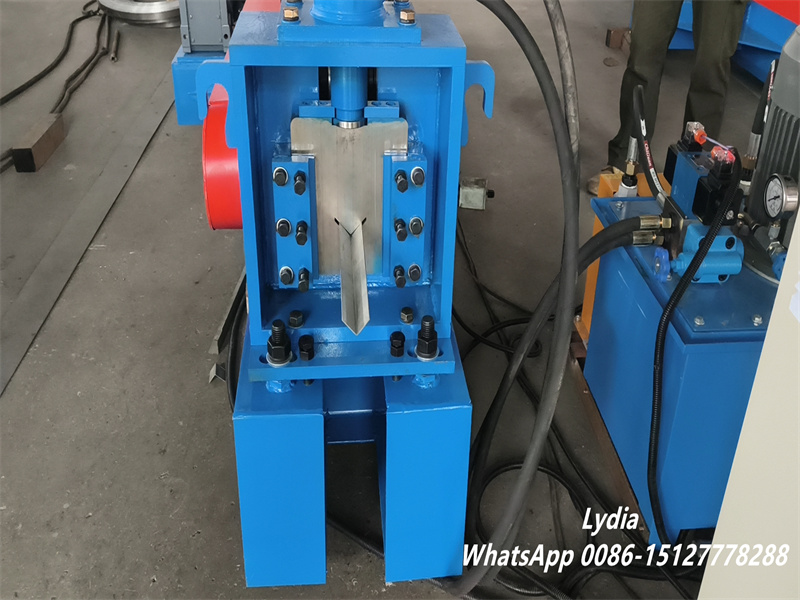

Hydraulic Cutting – Ensures precise cutting (tolerance around ±1mm/3m) without deforming the profile.

-

Collection Table – Receives the finished corner beads; adjustable design prevents bending or surface damage.

angle bead roll forming machine

angle bead roll forming machine

Why Choose a Corner Beads Roll Forming Machine?

-

Higher Productivity – Automated feeding, punching, forming, and cutting dramatically reduce manual labor.

-

Accurate & Consistent Output – Each bead has a uniform size, shape, and hole alignment.

-

Customization Options – Machines can be configured for different bead sizes and punching patterns.

-

Durability – Rollers made of Cr12 steel and tempered shafts extend service life.

-

Scalability – Suitable both for small production shops and for large manufacturers supplying the building industry.

Typical Applications

Corner beads manufactured by this machine are widely used in:

-

Drywall finishing (protecting wall edges)

-

Plasterboard and gypsum board systems

-

Ceiling and partition installations

-

Interior and exterior corners needing reinforcement

-

Public and commercial buildings where durability is essential

Conclusion

Investing in a corner bead roll-forming machine allows drywall and construction material producers to achieve faster output, better precision, and reduced costs. With automated punching, hydraulic cutting, and durable rollers, the equipment delivers professional-grade results for the US market. For manufacturers aiming to expand capacity and improve product quality, this machine is a strong addition to the production line.

angle bead roll forming machine

angle bead roll forming machine

The ZTRFM heavy-duty coil recoiler is engineered for handling narrow-width and light-gauge strip materials, ensuring

The metal coil slitting and recoiling machine is designed for processing narrow-width strips with high

High-Precision Coil Embossing Machine for Decorative and Structural Metal Applications As a trusted coil embossing

Ridge cap Roll Former-12” universal Ridge cap Ridge Cap Roll Former – Hems both

STAY IN THE LOOP