PU Sandwich Panel Production Line

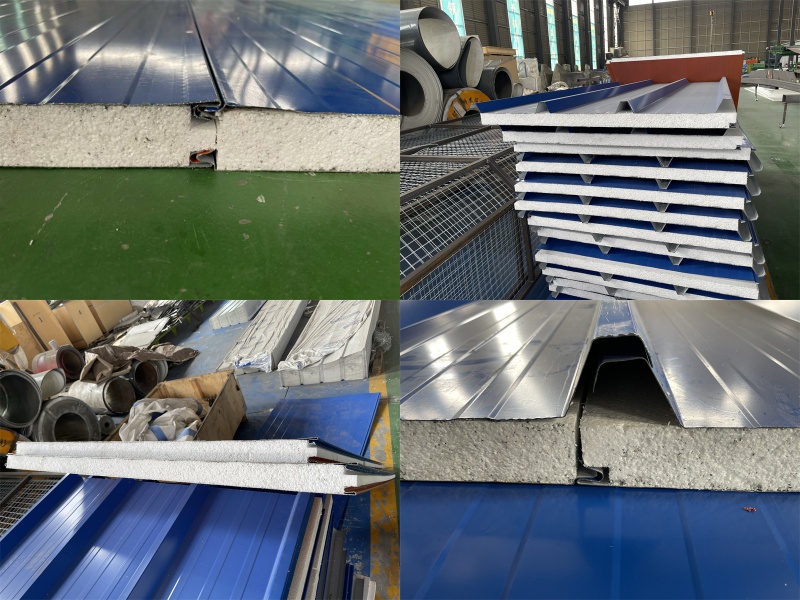

- This production line can produce both types of rock wool sandwich panels and EPS (foam) sandwich panels. The sandwich panels can be used for roof tile panels and wall panels.

- The sandwich panel will include the top sheet and the bottom sheet. For the roof tile sandwich panel will use the trapezoidal shape sheet as the top sheet. Both the bottom sheet and the top sheet will be formed by the composite machine. So we will prepare one roll forming machine to form the top sheet of the trapezoidal shape. The trapezoidal-shaped sheet can be customized according to the customer’s request.

- All the material will feed into the composite machine to form the sandwich panel. The glue will be sprayed on the sheet, then the steel sheet and the EPS(foam)/rock wool can be compounded together. During this process, the composite machine will start the heating system to ensure the panel sheet can be compounded effectively.

EPS Sandwich Roof Panel Roll Forming Machine

EPS Sandwich Roof Panel Roll Forming Machine Production Capacity:

- Annual output:600,000㎡, according to the yearly working days, daily working hours, and the products.

- Line speed: 5 m/min

| Total power: 50 kw

Machine dimension: about 40 m*2.5 m*2.8 m(L*W*H) Product thickness: 50-100 mm |

|

| Main core material: EPS & ROCK WOOL |

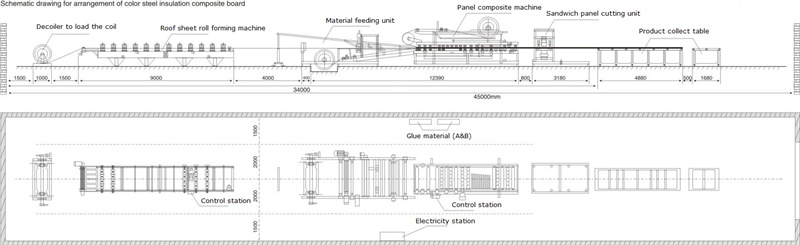

The Machine Working Flow:

EPS Sandwich Roof Panel Roll Forming Machine

EPS Sandwich Roof Panel Roll Forming Machine

Composite Sandwich Panel Roll Forming Machine – Technical Specifications

This document summarizes the technical specifications of the composite sandwich panel roll forming machine in a 3-column format.

| Item | Description |

| Series | Details |

| Raw Material | Standard |

| Material Thickness | 0.4 – 0.6 mm |

| Material Width | Max. 1250 mm |

| Decoiler Structure | Standard to match line |

| Loading Capacity | 5 Tons |

| Coil Inner Diameter | 450–550 mm |

| Decoiler Quantity | 3 Sets |

| Feeding Device | Installed by seller |

| Rolling Shaft Material | 45# Steel (chromed) |

| Roller Material | 45# Steel |

| Rolling Stations | 12 Stations |

| Working Speed | 12 m/min |

| Frame Structure | Steel plate + 350# H Steel |

| Transmission | Chains with cover |

| Work Power | 3 kW |

| Driving Stations | 16 Stations |

| Roller Material (Composite) | Rubber & 45# Steel |

| Machine Frame | Square tube welded |

| Panel Side Locking | Available |

| Working Speed | 5 m/min |

| PLC & Frequency Brand | Delta (Taiwan) |

| Screen Type | Touch Screen |

| Languages | English / Chinese / Arabic |

| Control Functions | Auto length setup, batch input |

| Inspection | Seller tests before shipment |

| Buyer’s Responsibility | Provide material coil |

| Machine Weight | Approx. 10 Tons |

| Machine Dimension | 40 m × 2.5 m × 2.8 m |

| Color | Blue (Customizable) |

| Power Supply | 380V / 50Hz / 3-Phase |

| Total Power | Approx. 50 kW |

| HS Code | 8455.2210.00 |

| Packing | For sea freight |

| Container Required | 2 × 40’ GP |

EPS Sandwich Roof Panel Roll Forming Machine

EPS Sandwich Roof Panel Roll Forming Machine

EPS Sandwich Roof Panel Roll Forming Machine

EPS Sandwich Roof Panel Roll Forming Machine

EPS Sandwich Roof Panel Roll Forming Machine

The ZTRFM heavy-duty coil recoiler is engineered for handling narrow-width and light-gauge strip materials, ensuring

The metal coil slitting and recoiling machine is designed for processing narrow-width strips with high

High-Precision Coil Embossing Machine for Decorative and Structural Metal Applications As a trusted coil embossing

Ridge cap Roll Former-12” universal Ridge cap Ridge Cap Roll Former – Hems both

STAY IN THE LOOP