LED Light Box Profile Roll Forming Machine

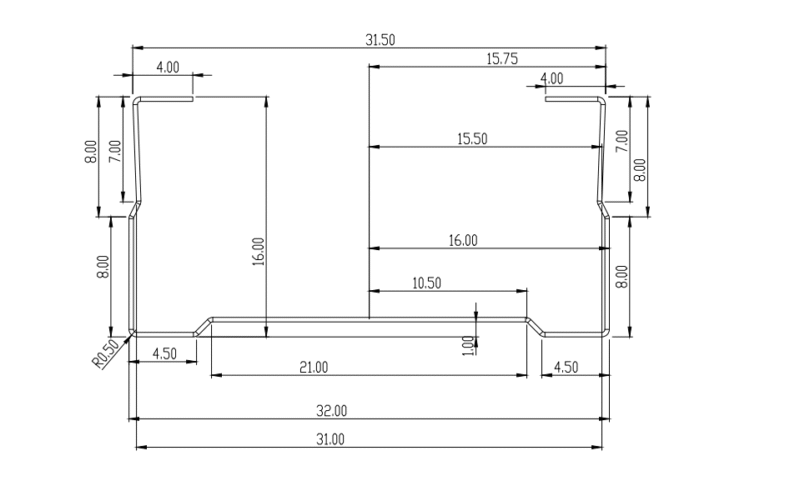

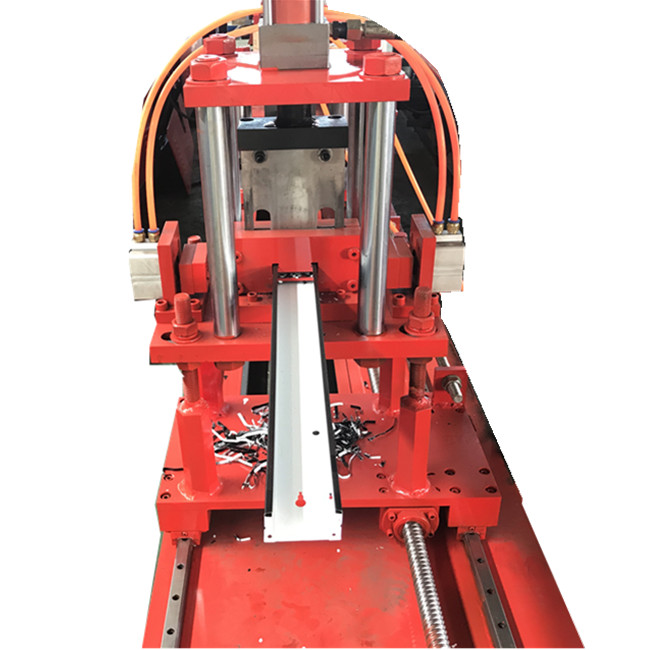

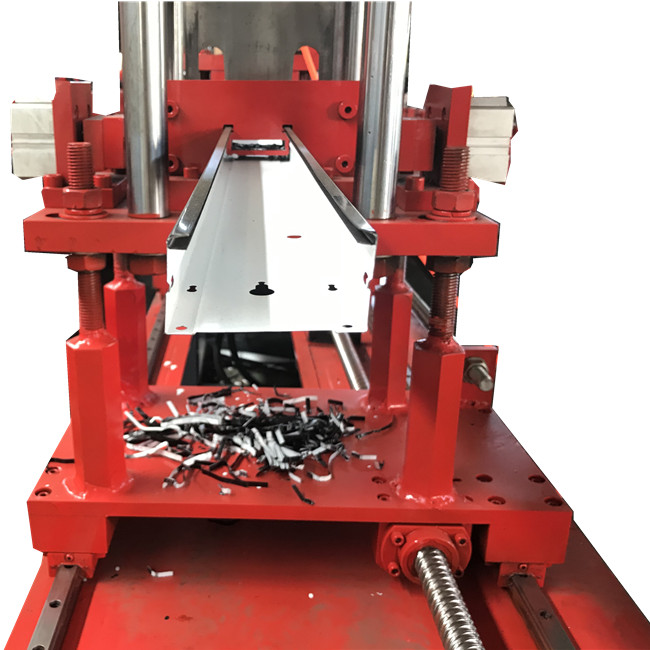

The Component Specifications of this roll forming system reflect its high-performance design and industrial-grade construction. The material feeding system features a servo-driven feeder powered by a 1.5 kW motor, delivering ±0.1 mm positioning accuracy and supporting coil widths up to 600 mm. In the punching unit, dual 10-ton hydraulic presses with CR12MoV tool steel dies enable both pre- and post-forming hole punching flexibility. The forming assembly consists of 22 forming stages and 6-wheel straightening, built on an 80×80 mm square tube welded frame with 25 mm Q235 steel side plates and a guided plate material guidance system. The drive system includes a 4 kW frequency-controlled main motor, a cycloidal reducer, and 38 mm hardened shafts (HRC 58–60), ensuring synchronized, gear-driven roller operation.

For cutting, a 2.2 kW hydraulic power unit drives a stationary shear with 3 mm-thick CR12 blades. The control system integrates Panasonic PLCs (Japan), Weinview HMIs (Taiwan), INVT inverters, and Schneider electrical components. Key advantages include GCr12 rollers with double quenching for wear resistance, servo-based dimensional tracking, adaptive profile width configuration, and precision feeding to reduce material waste. SKF 6206 bearings are used at critical points for long-term durability. The machine is compatible with various substrates such as pre-coated aluminum sheets, cold-rolled steel, and specialty metallic alloys, making it a versatile solution for metal forming operations.

For cutting, a 2.2 kW hydraulic power unit drives a stationary shear with 3 mm-thick CR12 blades. The control system integrates Panasonic PLCs (Japan), Weinview HMIs (Taiwan), INVT inverters, and Schneider electrical components. Key advantages include GCr12 rollers with double quenching for wear resistance, servo-based dimensional tracking, adaptive profile width configuration, and precision feeding to reduce material waste. SKF 6206 bearings are used at critical points for long-term durability. The machine is compatible with various substrates such as pre-coated aluminum sheets, cold-rolled steel, and specialty metallic alloys, making it a versatile solution for metal forming operations.

LED light box profile rolling forming machine

| Subsystem | Specifications |

|---|---|

| Material Feeding | Servo feeder (1.5 kW), ±0.1 mm accuracy, up to 600 mm coil width |

| Punching Unit | Dual 10-ton hydraulic presses, CR12MoV dies, flexible punching |

| Forming Assembly | 22 forming stages, 6 straighteners, Q235 frame, guided plates |

| Drive System | 4 kW motor, cycloidal reducer, 38 mm shafts, gear-driven rollers |

| Cutting Module | 2.2 kW hydraulic shear, 3 mm CR12 blades |

| Control System | Panasonic PLC, Weinview HMI, INVT inverter, Schneider electrics |

| Key Features | ±0.1 mm feeding accuracy, HRC 58-60 rollers, SKF 6206 bearings |

| Material Compatibility | Pre-coated aluminum, cold-rolled steel, metallic alloys |

Primary Application:

The LED Light Box Profile Roll Forming Machine, also known as the T5 Profile Rolling Machine, is designed to manufacture aluminum profiles used in LED light box frames. These profiles are widely applied in:

-

Outdoor advertising light boxes

-

Indoor display frames

-

Light guide panel frames

-

Ultra-thin LED light boxes

-

Signboard frameworks

-

Commercial spaces, shopping malls, subways, airports, and public lighting systems

The machine is capable of producing T5, T8, T10, L-shape, C-shape, U-shape, rectangular, and customized aluminum profiles, meeting various structural and aesthetic requirements for light boxes.

LED light box profile rolling forming machine

LED light box profile rolling forming machine

LED light box profile rolling forming machine

The ZTRFM heavy-duty coil recoiler is engineered for handling narrow-width and light-gauge strip materials, ensuring

The metal coil slitting and recoiling machine is designed for processing narrow-width strips with high

High-Precision Coil Embossing Machine for Decorative and Structural Metal Applications As a trusted coil embossing

Ridge cap Roll Former-12” universal Ridge cap Ridge Cap Roll Former – Hems both

STAY IN THE LOOP