ZTRFM’s India 1450 mm feeding roofing sheet roll forming machine is engineered for high-capacity metal roofing production. Featuring an 80 mm solid shaft housed in a robust H-beam frame, it effortlessly handles color-coated steel coils up to 1450 mm wide and 0.3–0.8 mm thick. With 24 forming stations, it runs at 10–15 m/min and integrates either manual or hydraulic decoilers, a 5.5 kW main motor, and a 3 kW hydraulic cutter to deliver precise, consistent panels. Fully certified to CE and ISO standards and backed by a one-year warranty plus optional on-site support, this line answers India’s need for durable, large-format roofing sheet manufacture.

Advantages of India 1450 mm Feeding Roofing Sheet Roll Forming Machine

Wide-Format Capability: Processes 1450 mm coils directly, eliminating side-trim steps and increasing throughput by up to 20%.

Heavy-Duty Durability: Reinforced frame and shaft design minimize maintenance and extend service life.

High Precision: Twenty-four forming stations deliver tight profile tolerances, reducing waste.

Comprehensive Support: Includes a year of warranty coverage, optional on-site commissioning, and lifetime technical advice.

Overview of India 1450 mm Feeding Roofing Sheet Roll Forming Machine

This machine transforms wide coils directly into corrugated or trapezoidal panels without repeated width adjustments. Its heavy-duty 80 mm shafts resist deformation under high material stresses, while the 24-roll sequence produces uniform profiles with smooth finishes from start to finish.

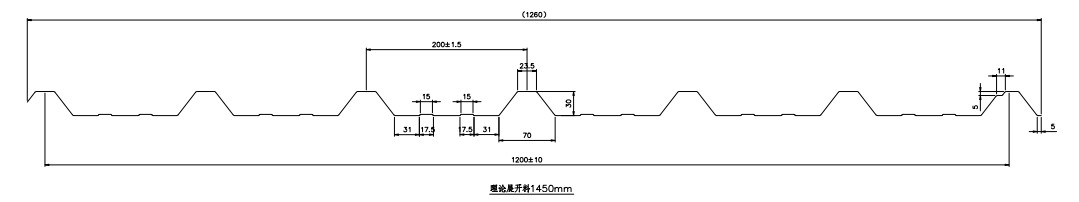

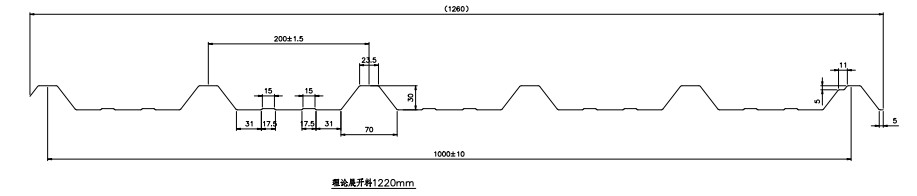

The Drawing Profile

Technical Specifications of India 1450 mm Feeding Roofing Sheet Roll Forming Machine

| Specification | Detail |

| Coil Width Capacity | 1450 mm |

| Material Gauge | 0.3–0.8 mm |

| Line Speed | 10–15 m/min |

| Forming Stations | 24 |

| Shaft Size | 80 mm diameter |

| Main Drive Power | 5.5 kW |

| Hydraulic Drive Power | 3 kW |

| Frame Thickness | 16 mm wall-plate H-beam |

| Decoiler Choices | 5 T manual stand or hydraulic unwinder |

| Cutting Accuracy | Hydraulic shear, ±1.5 mm |

| Control Platform | PLC with touchscreen interface |

| Electrical Hardware | Industry-grade relays and encoders |

| Footprint (L×W×H) | Approx. 7.5 × 1.8 × 1.5 m |

| Machine Mass | Approx. 5 t |

| Warranty | 12 months |

| Certifications | CE and ISO |

Core Components of India 1450 mm Feeding Roofing Sheet Roll Forming Machine

Solid 80 mm Shafts: Heat-treated 45# steel cores with chrome plating maintain alignment and resist wear.

Decoiler Assembly: A robust manual stand (5 t capacity) expands 460–520 mm coils; an optional hydraulic unit automates feeding.

Frame Structure: The 16 mm H-beam design eliminates vibration, enabling precise profile forming at higher speeds.

Hydraulic Shear Unit: Driven by a 3 kW pump, GCr12MoV blades provide distortion-free, length-accurate cuts.

Control Cabinet: Industry-standard PLC and touchscreen interface paired with reliable electrical components ensure user-friendly operation.

Production Workflow of India 1450 mm Feeding Roofing Sheet Roll Forming Machine

Coil Setup: Mount the pre-coated or galvanized steel on the chosen decoiler.

Feeding & Leveling: Guide the strip through entry rollers to remove pre-bend.

Profile Forming: Pass material through 24 sequential roll stations to form the trapezoidal shape.

Length Control: The PLC system continuously tracks sheet length.

Hydraulic Cutting: Upon reaching preset lengths, the shear trims panels with ±1.5 mm precision.

Stacking: Exit tables or powered stackers collect finished sheets for immediate packaging.

Ideal Applications for India 1450 mm Feeding Roofing Sheet Roll Forming Machine

Large-Span Industrial & Commercial Roofing for factories and warehouse projects.

Agricultural Facilities requiring durable, corrosion-resistant roofing panels.

Residential & Public Buildings offering consistent, attractive coverings for homes, schools, and hospitals.

Export & OEM Projects, where international standards and wide-format capabilities are essential.

More information, please check our website and contact us at any time.

【ZHONGTUO】Our official website:

https://www.rollsformingmachines.com

👉Lydia Gao / https://www.youtube.com/@zhongtuomachine/videos

▷ ▷Don’t forget to subscribe to us for more information that you are interested in ◁◁

📞 whatsapp/wechat:0086-15127778288

Email:cnzt008@zhongtuocn.com

If you need information about this topic you can CHECK our other video at these links:

1.Trapezoidal sheet roofing panel roll forming machine

2.Corrugated sheet roll forming machine

3.Step tile/Roof tile roll forming machine

4.Floor deck roll forming machine

5.CZ purlin roll forming machine

6.Light steel stud and track roll forming machine

7.Main Tee Cross Tee bar roll forming machine for ceiling

8.Highway guardrail roll forming machine

9.Embossing machine

10.Cut to length machine

11.Other related machines which are support customization

The ZTRFM heavy-duty coil recoiler is engineered for handling narrow-width and light-gauge strip materials, ensuring

The metal coil slitting and recoiling machine is designed for processing narrow-width strips with high

High-Precision Coil Embossing Machine for Decorative and Structural Metal Applications As a trusted coil embossing

Ridge cap Roll Former-12” universal Ridge cap Ridge Cap Roll Former – Hems both

STAY IN THE LOOP