Hydraulic Press Brake 350T3200 with TP10S CNC System, High-Precision Torsion Bar Bending Machine

We are pleased to offer our 350T3200 Torsion Bar Hydraulic Press Brake, a heavy-duty and high-performance bending solution designed for sheet metal fabrication with utmost precision and efficiency. Equipped with the TP10S CNC controller, this machine is suitable for various applications in manufacturing industries such as enclosures, cabinets, panels, and structural components.

Key Features & Design Highlights

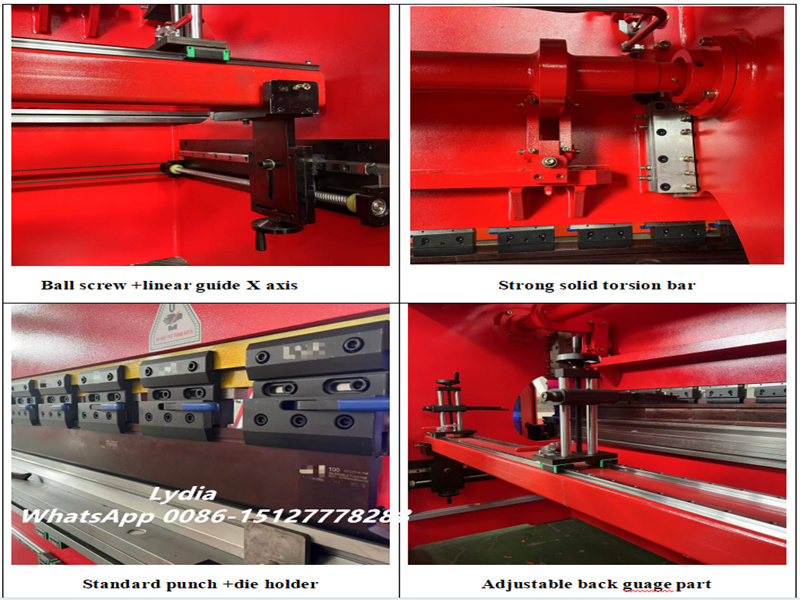

- Integrated light function and clear safety warning signs

- Equipped with ball screw and linear guide for backgauge X-axis

- Solid torsion bar ensures synchronized and accurate bending

- Durable punch & die holder for quick tool changes

- Adjustable backgauge for flexible sheet positioning

- Easy-to-install with basic packaging and clear labeling for connections

350T3200 TORSION BAR HYDRAULIC PRESS BRAKE MACHINE

Technical Specifications of Hydraulic Swing Beam Shearing Machines

| Item | Details |

|---|---|

| Nominal Pressure | 3500 KN (350 Ton) |

| Working Table Length | 3200 mm |

| Distance Between Columns | 2600 mm |

| Throat Depth | 400 mm |

| Slide Stroke | 250 mm |

| Max. Opening Height | 570 mm |

| Max. Working Pressure | 26 MPa |

| Backgauge Range | 500 mm |

| Slider Speed (Down/Working/Up) | 120 / 8 / 110 mm/s |

| Main Motor Power | 22 kW |

| Stroke Servo Motor | 0.85 kW, EMG Series |

| Backgauge Servo Motor | 0.85 kW, EMG Series |

| Oil Pump | CPO-40-P-10R, 40ml/r, 35MPa |

| Machine Dimensions (L×W×H) | 4500 × 1900 × 2850 mm |

| Machine Weight | 15,500 kg |

| Oil Tank Capacity | 420 kg (46# Anti-wear oil) |

350T3200 TORSION BAR HYDRAULIC PRESS BRAKE MACHINE

Main Components

| Component | Brand / Feature |

|---|---|

| CNC System | TP10S (China) – accurate angle control |

| Main Motor | Wannan – low noise, strong pressure |

| Hydraulic Valve | XINLI Group – sensitive, anti-jamming |

| Oil Pump | USA Sunny – durable and quiet |

| Servo System | Estun EMG Series + EASYCUT ES10 Drive |

| Fittings | JS-Germany standard – high sealing |

| Cylinder | WUYANG – 20+ years of manufacturing experience |

| Punch & Die | 42CrMo, HRC 47±2°, customized as requested |

Optional Configurations

| Option | Details |

|---|---|

| Safety Protection | Light Curtain / Laser System |

| Motor Brand | Siemens / Wannan |

| Cooling System | Air Cooler or Oil Cooler |

| Molds | Special molds upon customer drawing |

| CNC System Upgrade | DELEM DA41T, E300P |

| Crowning System | Mechanical crowning for precision |

350T3200 TORSION BAR HYDRAULIC PRESS BRAKE MACHINE

350T3200 TORSION BAR HYDRAULIC PRESS BRAKE MACHINE

350T3200 TORSION BAR HYDRAULIC PRESS BRAKE MACHINE

Shipping & Delivery

- Packaging: Simple plastic cover for protection

- Container Requirement: 1× 20 ft Open Top Container

- Delivery Time: 35 working days after deposit

This hydraulic press brake provides excellent bending accuracy, durability, and customization options to meet demanding fabrication needs. Whether you’re manufacturing large sheet metal parts or precision components, the 350T3200 is an efficient and powerful choice.

If you need the document in PDF or Word format, or a Chinese version, please let me know.

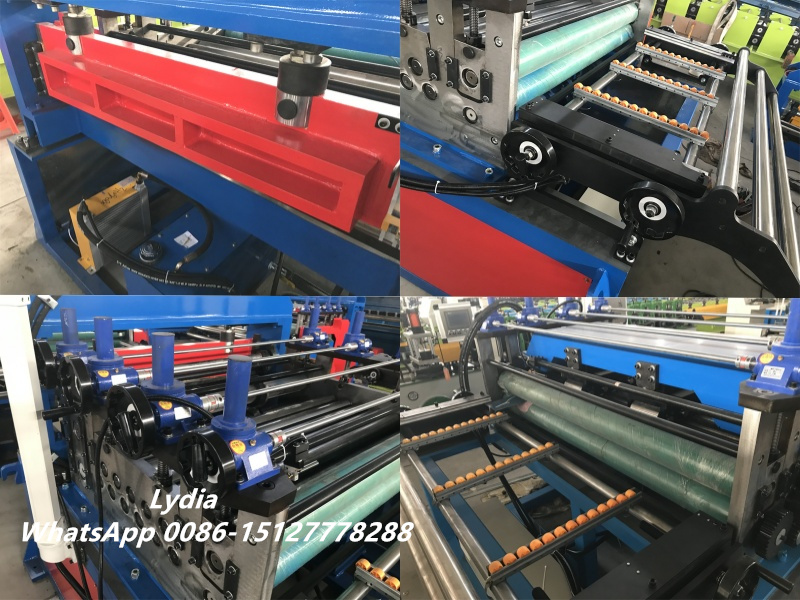

Engineered by Zhongtuo for Precision and Surface Protection As patio and pergola structures become more

Zhongtuo Industrial Cable Tray Roll Forming Production Line Zhongtuo Cable Tray Roll Forming Machine is

Full Automatic Steel Supermarket Shelves Storage Rack Upright Pillar Roll Forming Machine Improve Warehouse Efficiency

Cable Ladder & Cable Tray Roll Forming Machine High-Efficiency Steel Side Rail Forming Machine for

STAY IN THE LOOP