At ZTRFM (Zhongtuo Roll Forming Machinery), we understand that a high-quality floor deck decking building roll forming machine must not only be well-built, but also well-delivered. That’s why we have developed a strict, professional packing and shipping process to guarantee the safe arrival of every roll forming machine we export.

Step 1: Thorough Pre-shipping Inspection

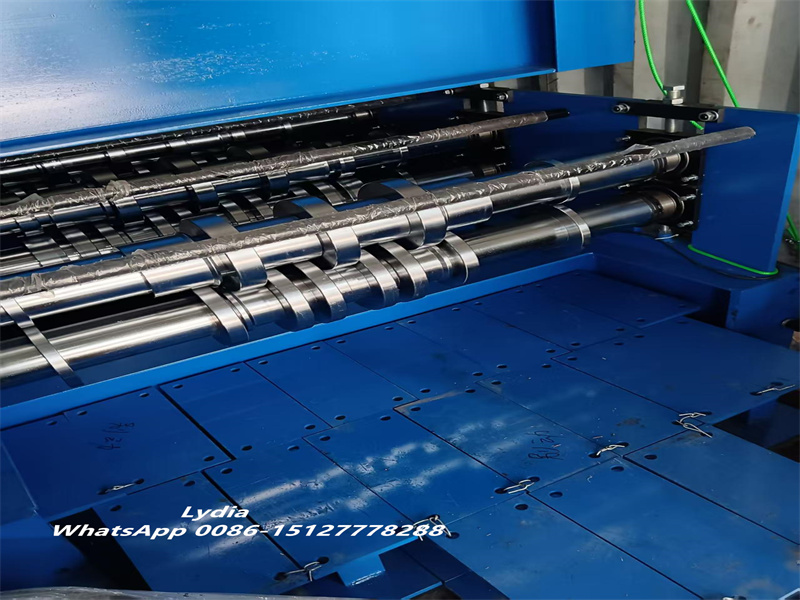

Before packing, our engineers carefully inspect all core components of the machine, including the main frame, electrical cabinet, hydraulic system, and forming rollers. Any signs of damage or wear are documented and resolved. All surfaces are cleaned, with extra attention to gears, chains, and electrical parts to remove dust, grease, and potential contaminants.

Packing and Shipping Process for Floor Deck Roll Forming Machine

Step 2: Preparing the Container for Loading

Our team checks the interior of the container or truck bed, ensuring a smooth, flat surface free of debris or sharp edges. Custom-built steel or wooden support blocks—engineered to distribute weight evenly—are strategically placed inside the container.

Packing and Shipping Process for Floor Deck Roll Forming Machine

Step 3: Professional Equipment Handling

Using overhead cranes and forklifts, the machine is slowly lifted and precisely guided into position. Experienced staff provide instructions via radio or hand signals to ensure that the machine’s weight-bearing points align exactly with the support blocks.

Packing and Shipping Process for Floor Deck Roll Forming Machine

Step 4: Stabilizing and Securing the Machine

Once in place, the floor deck decking building roll forming machine is leveled and secured. Wooden wedges and rubber shims are inserted into any gaps between the machine and supports. We then fix the machine using rust-proof steel cables, tensioned diagonally to prevent shifting. Rubber pads are applied where cables contact the machine to avoid damage or marks.

Packing and Shipping Process for Floor Deck Roll Forming Machine

Packing and Shipping Process for Floor Deck Roll Forming Machine

Step 5: Protecting Sensitive Parts

Hydraulic stations and other detachable parts are wrapped in film to prevent scratches. High-elasticity rubber buffers are placed around all sides to absorb vibration during long-distance transport.

Packing and Shipping Process for Floor Deck Roll Forming Machine

Step 6: Final Safety Test and Seal

Before closing the container, our team performs a shake test to confirm the floor deck decking building roll forming machine. Only when the equipment is absolutely secure do we seal the container for shipment.

Packing and Shipping Process for Floor Deck Roll Forming Machine

Packing and Shipping Process for Floor Deck Roll Forming Machine

The ZTRFM heavy-duty coil recoiler is engineered for handling narrow-width and light-gauge strip materials, ensuring

The metal coil slitting and recoiling machine is designed for processing narrow-width strips with high

Zhongtuo Roll Forming Machinery Partners with Lange Steel Network to Launch a New Era of

High-Precision Coil Embossing Machine for Decorative and Structural Metal Applications As a trusted coil embossing

STAY IN THE LOOP