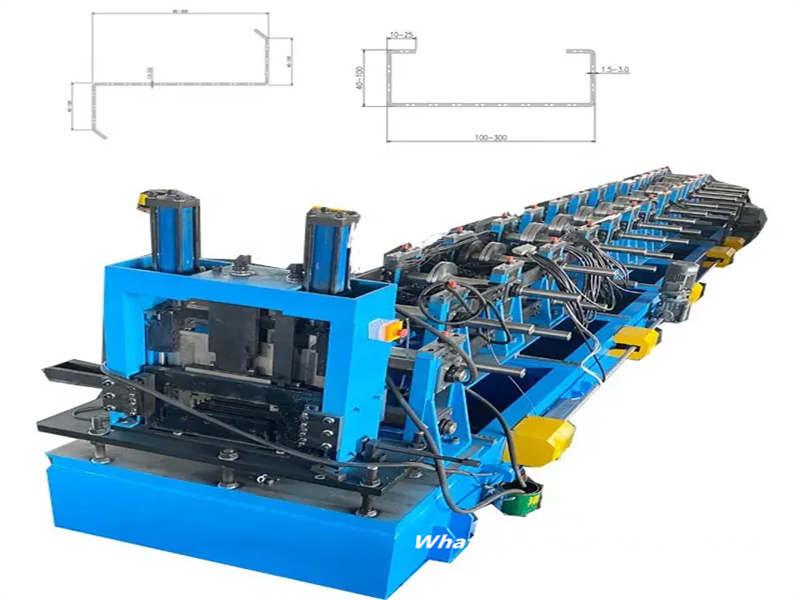

Regarding Sigma and M purlin profiles, we offer a tailored roll forming Method based on size and thickness requirements. For manufacturers needing flexible production, we provide systems that allow automated adjustment of height and width to produce multiple purlin types. The market offers both manual and fully automatic C/U/Z/M purlin forming lines—manual change systems typically require about 2 minutes to switch profiles, while fully automated designs allow for seamless changes in just seconds, though at a higher cost.

Sigma Purlins M purline rolling forming machine

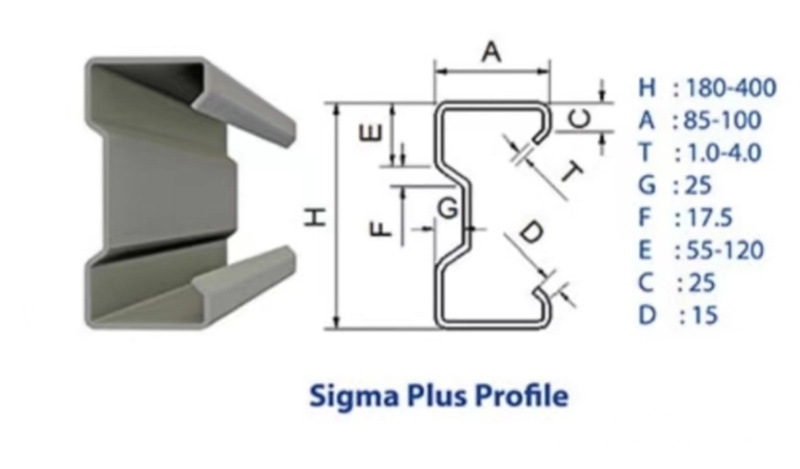

The Drawing Profile :

Sigma Purlins M purline rolling forming machine

The Technical Specifications Of M Prulin Machine:

| Item | Details (English) |

| Material | Galvanized Steel Sheet, Cold Rolled Steel |

| Thickness Range | 1.5–2.5 mm |

| Steel Grade | Q345 |

| Test Plate Thickness | 2.5 mm |

| Feeding Width | According to the profile |

| Uncoiler | 5 Ton Manual Uncoiler |

| Coil Inner Diameter | 500 mm |

| Coil Width | 600 mm |

| Feeding & Leveling | One set of feeding guides, Five-roller leveler |

| Pre-Punching Unit | One-position front punching device (shared hydraulic power) |

| Hydraulic Power (shared) | 11 kW |

| Main Forming Machine | One unit |

| Main Motor Power | 15 kW (Servo Motor) |

| Transmission | 1.5-inch chain drive |

| Roller Stations | 18 forming stations |

| Forming Speed | Approx. 8–20 m/min |

| Frame Structure | H450 steel beam frame, side plate thickness 18 mm |

| Shaft Diameter | 75 mm, material 40Cr, precision machined and heat treated |

| Roller Material | GCr15, precision machined, heat treated (HRC 56–58) |

| Cutting Device | Hydraulic post-cut system with 3-blade shearing |

| Hydraulic Power (shared) | 11 kW (shared with punching and front shearing) |

| Blade Material | Cr12Mov, heat-treated |

| Control System | One computer control console |

| Functions | Auto length measurement and cutting control |

| Control Components | PLC (Delta/Schneider), Touch Screen (KAUTO), Encoder (Omron), Inverter (Delta/Schneider) |

| Output Racks | 3 non-powered racks |

| Voltage Standard | 380V / 50Hz / 3 Phase |

The M Purlin Roll Forming Machine is engineered to precisely and efficiently fabricate M-shaped purlins. Utilizing advanced forming technology, this equipment smoothly transforms flat metal sheets into uniform, structurally sound M Purlin profiles. Its adaptable design supports the production of various sizes and configurations, making it ideal for a wide range of construction applications. With its high-precision output, the machine enhances manufacturing productivity, minimizes labor input, and ensures consistent quality, making it a valuable asset for producing dependable purlins used in commercial, industrial, and residential projects.

Sigma Purlins M purline rolling forming machine

Sigma Purlins M purline rolling forming machine

Downspout Water Gutter Pipe Making Roll Forming Machine An efficient rainwater drainage system starts with

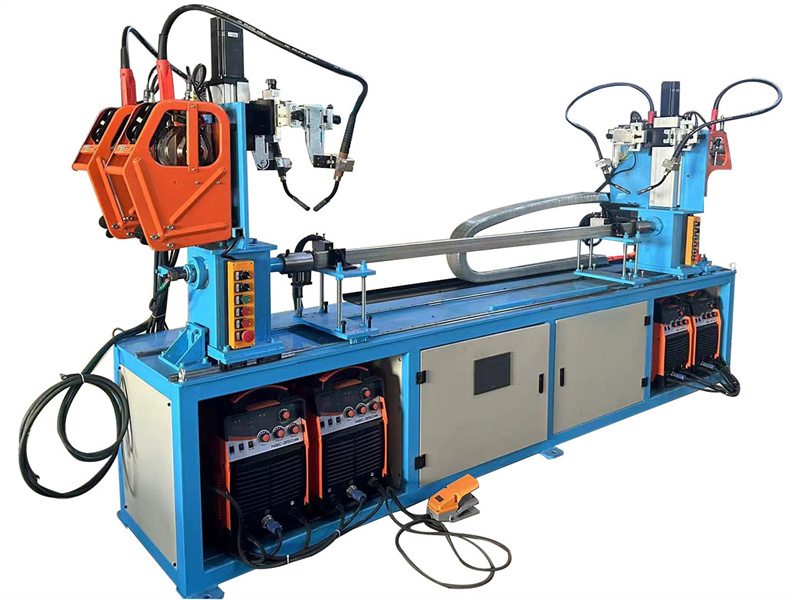

Double-Sided CO₂ / MIG Welding Machine The 2026 New High-Precision Seam-Welded Square & Rectangular Tube

Professional C & Z Purlin Roll Forming Machine Heavy-Duty Automatic Machine for Structural Steel Production

Round Downpipe Roll Forming Machine & Aluminum Gutter Guard Production Line Efficient rainwater drainage is

STAY IN THE LOOP