The TR35 Trapezoidal Roofing Sheet Machine is a high-performance industrial forming solution, engineered for the efficient production of color-coated steel roofing panels. Its speed, accuracy, and durability make it a trusted choice in modern construction. Especially popular in Algeria, the TR35 profile meets diverse market demands with outstanding performance and quality.

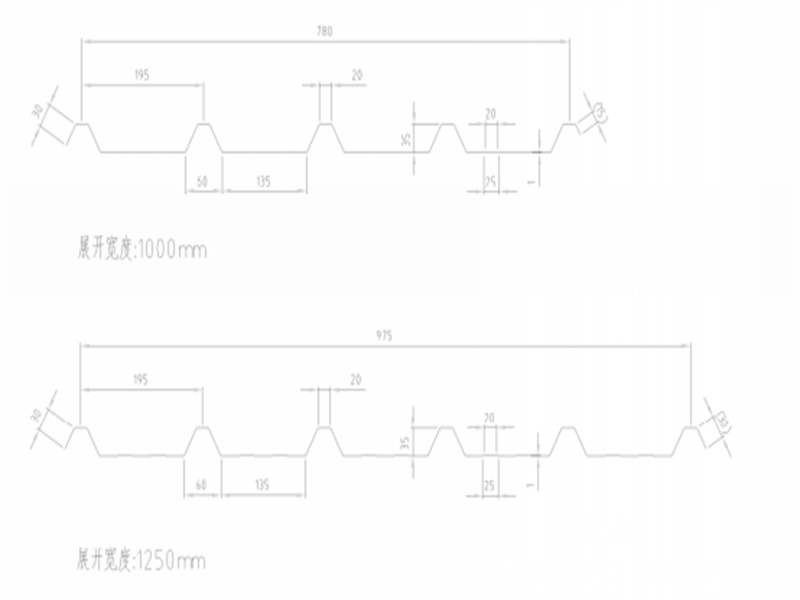

1. TR35 Trapezoidal Roofing Sheet Machine Profile Drawing

2. TR35 Trapezoidal Roofing Sheet Machine Key Advantages

- High-Speed and Efficient Production: Advanced transmission systems and smart control algorithms allow continuous, high-speed forming, significantly improving productivity.

- Enhanced Precision and Stability: The shaft is processed twice on a lathe, once on a grinder, and twice on a milling machine to ensure high dimensional accuracy and tight roller fit. Additionally, rollers and shafts are precisely matched with integrated key slots, preventing slippage—a critical design feature many competitors overlook.

- Stable Feeding System: The entry section adopts a linear guide pillar structure, equipped with front and rear pinch rollers and a manual pull blade, ensuring smooth material feeding, easy adjustment, and scratch-free surface protection.

- Durable and Reliable Cutting System: The integrated bolt-connected cutting frame is designed for easy maintenance. The blade uses an insert-type double-row bolt design to ensure durability and clean cuts. The servo tracking cutter is also equipped with automatic oil injection and a cast steel oil pipe, enhancing lubrication and long-term operation.

- Surface Protection for Galvanized Sheets: An automatic oil or emulsified fluid spraying system prevents zinc layer detachment and roller sticking issues, particularly effective for galvanized coils.

- Smart Design for Long-Term Operation: Equipped with a counter protection baffle to prevent material from hitting the counter, and uses grade 8.8 bolts with flat and spring washers to avoid loosening caused by vibration during transport or operation.

- Enhanced Frame Strength and Longevity: The machine frame includes slanted supports and vertical ribs to prevent deformation or twisting during hoisting and installation, ensuring long-term structural reliability.

- Double Lock Nut with Thrust Washer: Each roller lock nut is secured with a double-nut structure and thrust washer, paired with the key slot design, to prevent loosening during high-speed operation.

- Improved Manual Pull Blade at Entry: The entry section’s manually operated pull cutter has been upgraded for enhanced durability and ease of use—please ensure this is updated on all quotations accordingly.

3. TR35 Trapezoidal Roofing Sheet Machine Technical Specifications

- Forming Stations: 25 precision-rolled stations for optimal profile shaping

- Machine Frame: Arch-type frame enhances structural integrity and load resistance

- Base Frame: Robust 400H steel beam for strong mechanical support

- Speed: 40–50 meters per minute

- Main Motor Power: 22kW

- Transmission: High-efficiency gearbox-driven system

- Cutting System: Servo tracking flying shear with automatic oiling and retractable support frame, which solves the problem of short panel output support

4. TR35 Trapezoidal Roofing Sheet Machine Application Scope

This machine produces trapezoidal roofing and wall panels extensively used in industrial buildings, warehouses, sports arenas, exhibition halls, airports, stations, and more. The panels provide excellent waterproofing, thermal insulation, and aesthetic appeal, and remain stable across various climate conditions and environmental settings.

As the demand for more precise, diverse, and efficient construction materials grows, the TR35 Trapezoidal Roofing Sheet Machine stands out as a key player in industrial roll forming. Its engineering excellence, production efficiency, and attention to structural detail make it an ideal solution for modern construction needs.

The ZTRFM heavy-duty coil recoiler is engineered for handling narrow-width and light-gauge strip materials, ensuring

The metal coil slitting and recoiling machine is designed for processing narrow-width strips with high

High-Precision Coil Embossing Machine for Decorative and Structural Metal Applications As a trusted coil embossing

Ridge cap Roll Former-12” universal Ridge cap Ridge Cap Roll Former – Hems both

STAY IN THE LOOP