Application of Glazed Tile Roof Sheet Roll Forming Machine

The glazed tile roof sheet roll forming machine is widely used for producing stylish and durable roofing sheets with high efficiency and accuracy. It transforms metal coils into well-shaped glazed tiles through a continuous and precisely controlled process.

As the material feeds through the machine, it is gradually formed by a series of rollers that work in perfect coordination with the conveyor. This setup not only ensures a smooth production flow but also delivers uniform quality across each sheet.

Thanks to its user-friendly design, the machine requires minimal manual intervention and is easy to operate and maintain. These advantages make it a reliable choice for manufacturers looking to streamline production while maintaining high standards in roofing products.

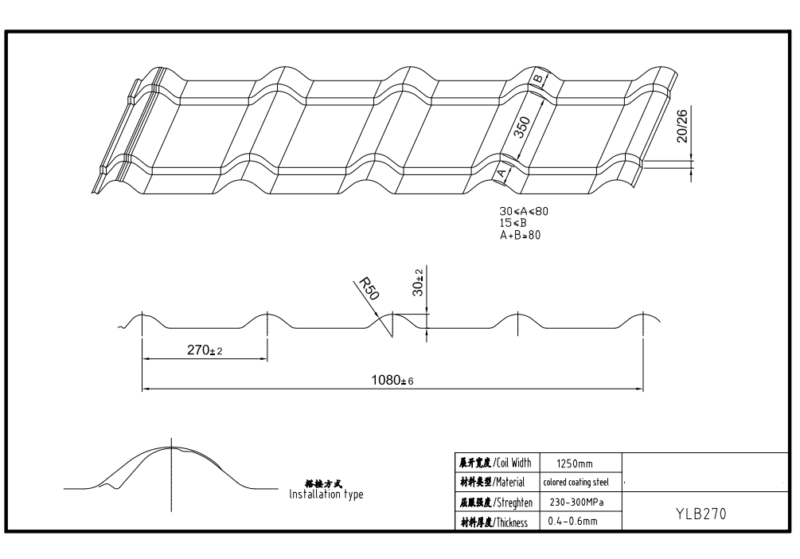

The Drawing Profile of Glazed Tile Roof Sheet Roll Forming Machine:

Finished Product Picture of Glazed Tile Roof Sheet Roll Forming Machine:

Glazed Tile Roof Sheet Roll Forming Machine

Glazed Tile Roof Sheet Roll Forming Machine Working Flow:

The Main Technical Parameter Of Glazed Tile Roof Sheet Roll Forming Machine:

| Series | Details | Parameter | Comment |

| Material | Raw material | Steel | Customer confirmed |

| Material thickness | 0.4-0.6 mm | ||

| Decoiler | Structure | Manual passive type | The standard one to match the production line |

| Single head type | |||

| Loading capacity | 1.5 Tons | ||

| Coil inner diameter | 450-550 mm | ||

|

Roll forming machine |

Guiding device | Placed on the machine by seller | |

| Rolling shaft material | 45# STEEL with tempering | ||

| Shaft diameter | 50 mm | ||

| Roller material | GB-Cr12 | ||

| Rolling station | 21+1 stations | ||

| Work speed | About 7-9m/min | ||

| Machine structure | Vertical memorial arch frame | ||

| Machine basic frame | Steel plate welded | ||

| Bearing | Roller bearing | Famous brand of Harbin | |

| Total Power | 21.55KW | ||

| Transmission | By gear | With cover | |

| Safety cover | available | ||

|

Appearance |

Good appearance with no burrs in steel body nor traces of rust or defects in painting.

Good electrical and hydraulic cable organization Car painting make the machine more glossy |

We confirm each detail can match the standard, ensure the machine is 100% new! | |

| Decoiler, we can change to hydraulic one if you need. | |||

| PLC control system | 1.Operation: screen+ button

2.MITSUBISH, Frequency |

||

| Hydraulic station | Famous Chinese brand | ||

More pictures of the machine:

The ZTRFM heavy-duty coil recoiler is engineered for handling narrow-width and light-gauge strip materials, ensuring

The metal coil slitting and recoiling machine is designed for processing narrow-width strips with high

High-Precision Coil Embossing Machine for Decorative and Structural Metal Applications As a trusted coil embossing

Ridge cap Roll Former-12” universal Ridge cap Ridge Cap Roll Former – Hems both

STAY IN THE LOOP