Modern construction projects demand highly efficient and precise equipment to produce structural components such as keels and light steel frames. The High-Speed Triangular Keel Roll Forming Machine and the Villa Keel Roll Forming Machine (ZTRFM-BS89-41) are two advanced production lines designed to meet the requirements of industrial, commercial, and residential steel framing solutions. Both machines incorporate automated processes, precise roll-forming technology, and durable components, ensuring stable operation and high-quality product output.

light gauge steel forming machine

High-Speed Triangular Keel Roll Forming Machine

The High-Speed Triangular Keel Roll Forming Machine is designed for the rapid production of light steel triangular keel profiles. Using galvanized steel strips as raw material, the machine automates the entire process—uncoiling, roll forming, cutting, and stacking—while maintaining dimensional accuracy and surface quality. Its servo-tracking hydraulic cutting system ensures smooth and precise cuts without interrupting production flow.

light gauge steel forming machine

light gauge steel forming machine

Key Features of Triangular Keel Roll Forming Machine

- Roll forming speed up to 50m/min

- Precision forming with dimensional tolerance within ±0.5mm

- Heavy-duty frame and roll design for long service life

- PLC + touch screen control system for easy operation and order management

Technical Specifications

| Parameter | Specification |

|---|---|

| Material Thickness | 0.28 – 0.5 mm |

| Roll Forming Stands | 16 groups |

| Shaft Diameter | φ48 mm (40Cr, quenched & tempered) |

| Roller Material | Cr12MoV, HRC60–62 (precision ground) |

| Cutting System | Hydraulic cutting, 4KW motor |

| Forming Motor Power | 7.5KW |

| Line Speed | 0–50 m/min |

| Control System | PLC (Inovance) + Touch Screen (Inovance) |

| Machine Dimensions | ~5000×700×1500mm |

| Total Line Length | ~13m |

light gauge steel forming machine

light gauge steel forming machine

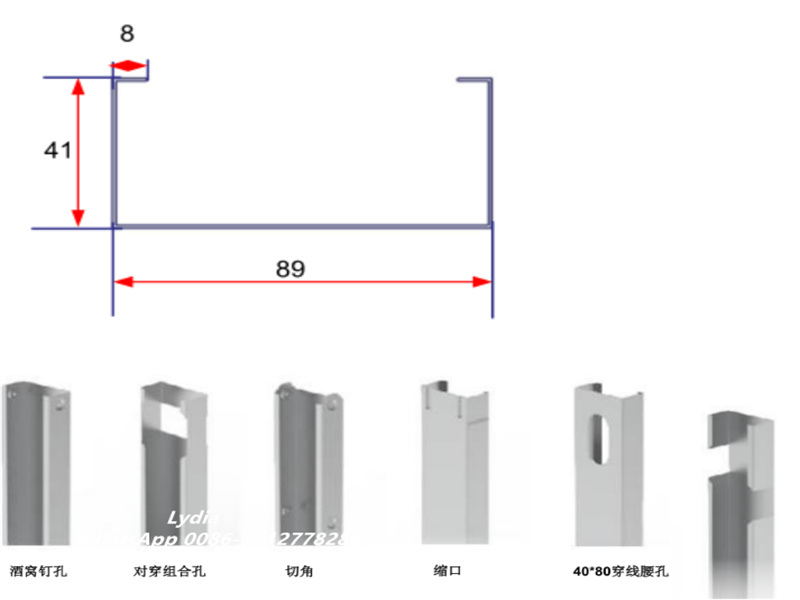

Villa Keel Roll Forming Machine (ZTRFM-BS89-41)

The Villa Keel Roll Forming Machine is specially designed for producing structural components used in modern light steel villas. It processes G550 high-strength galvanized steel strips with thicknesses ranging from 0.8–1.2mm, integrating functions such as leveling, punching, roll forming, shrinking, cutting, and marking. Equipped with an integrated inkjet printer and advanced NC control system, this machine ensures both structural precision and traceability.

Key Features

- Supports multiple punching molds (up to 7 sets) for versatile applications

- Precision-controlled forming with servo motor drive

- Full NC control with 21-inch touch screen & wireless remote operation

- High durability with NSK bearings and Cr12MoV hardened rollers

Technical Specifications

| Parameter | Specification |

|---|---|

| Material | G550 Galvanized Steel Strip |

| Thickness | 0.8 – 1.2 mm |

| Roll Forming Stands | 12 groups |

| Shaft Diameter | φ48 mm (40Cr, quenched & tempered HRC28–32) |

| Roller Material | Cr12MoV, HRC60–62 |

| Punching System | 7 sets of punching molds, 9 hydraulic cylinders |

| Cutting System | Hydraulic cutting, 5.5KW motor |

| Forming Motor Power | 7.5KW Servo |

| Line Speed | 8–50 m/min |

| Control System | Full NC Light Steel Villa System + 21” Touch Screen |

| Machine Dimensions | ~5000×1300×1850mm |

| Total Line Length | ~15m |

Both the High-Speed Triangular Keel Roll Forming Machine and the Villa Keel Roll Forming Machine are built with advanced roll forming technology, precision hydraulic systems, and intelligent PLC control. While the Triangular Keel Machine is ideal for high-speed, large-volume production of lightweight keels, the Villa Keel Machine provides multifunctional capabilities tailored for the structural needs of modern light steel villas.

These machines ensure efficiency, precision, and durability, making them essential equipment for steel structure manufacturers.

light gauge steel forming machine

light gauge steel forming machine

The ZTRFM heavy-duty coil recoiler is engineered for handling narrow-width and light-gauge strip materials, ensuring

The metal coil slitting and recoiling machine is designed for processing narrow-width strips with high

High-Precision Coil Embossing Machine for Decorative and Structural Metal Applications As a trusted coil embossing

Ridge cap Roll Former-12” universal Ridge cap Ridge Cap Roll Former – Hems both

STAY IN THE LOOP