Features of the Punching Line

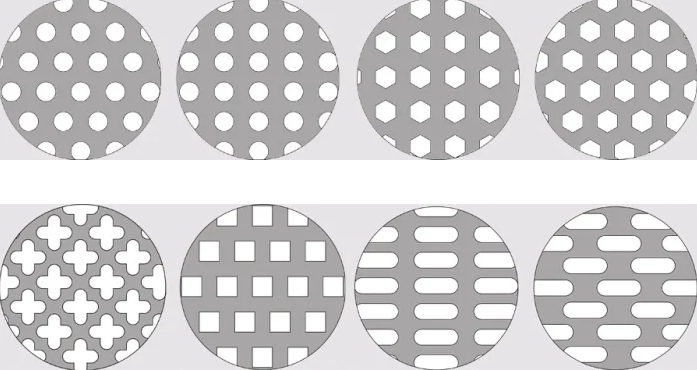

ZTRFM carries inventory of Sheet Perforated Line Roll Forming Machine in China with a vast selection of sizes, gauges, and hole types available. In both high-end and industrial settings, Perforated Metal brings strength and style to enclosures, partitions, sign panels, guards, screens, and other structures. This dynamic product line offers ventilation, versatility, and a high strength-to-weight ratio. Perforated Metal is also an excellent product for filtration (sound, liquid, light, etc.) applications

Perforated Steel Sheet Machine is a sheet product that has been punched with a wide variety of hole sizes and patterns providing an aesthetic appeal. Perforated Steel Sheet offers savings in weight, passage of light, liquid, sound and air, while providing a decorative or ornamental effect. Perforated Steel Sheets are common in interior and exterior design.

Specifications: Hot Rolled Steel, Cold Rolled Steel

Applications: High-speed sound-absorbing panels, suspended ceilings, hospital chair backs,security, sifting, machinery guards, enclosures, sign panels, & more.

Workability: Easy to Weld, Cut, and Form with proper equipment

Mechanical Properties: Magnetic, Tensile = 50K +/-, Yield = 35K +/-

thickness X hole diameter X spacing

Request Sizes: 1ft x 4ft, 2ft x 4ft, 4ft x 4ft, 4ft x 8ft, or Cut to Size

We can design our perforation sheet production machine line according to demands of our customers. So that we can match with different perforated sheet working thickness and width range. Also we have different speed alternatives on our sheet metal perforation machine line.

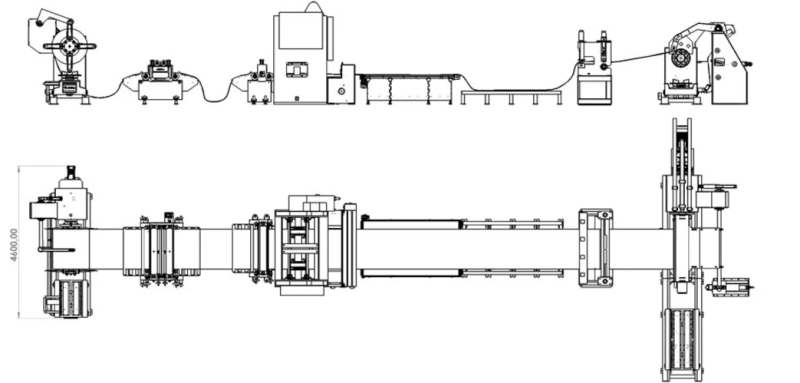

Work flow:

Hydraulic decoiler — Servo feeder — Punching — Damping device S rollers — Recoiler (or could be cut to length)–> or main rolling forming machines

For the final shape of perforated metal sheet products produced on our sheet metal perforation machine line, we can customize the mold system based on the specific requirements of our customers. We perform the necessary calculations to design the perforation molds and determine the required tonnage for the eccentric press used in the perforation production line. We work closely with our customers to ensure that the desired perforation patterns are accurately reflected in the finished perforated sheets.

Decoiler

Type : electric,Hydraulic

Motor power:0.75kw

Inner diameter:450-550mm(as required)

Capacity: 3T、10T

Decoiler dimension: 1000*1000*1200mm

Servo feeder

Type: model NCF-300

Servo motor power:1.5kw

Control system: by PLC

Feature: high precision, high speed

Punching machine & punching dies

Punching machine model: JF21-63 (Yangli brand, famous brand)

Punching machine pressure: 63T

Power : by Mechanical

Mold material: CR12

Speed: 120 times/min

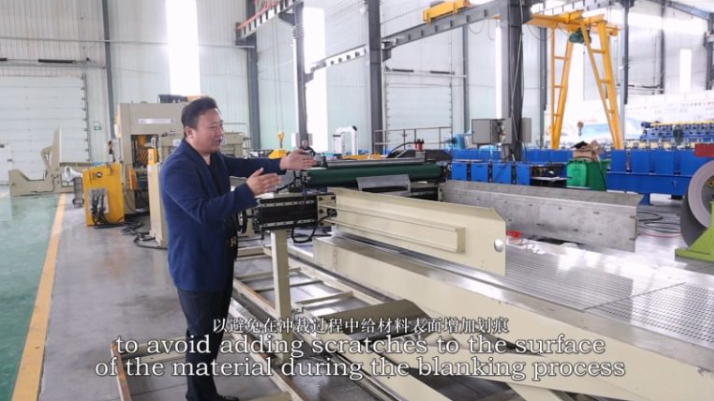

Engineered by Zhongtuo for Precision and Surface Protection As patio and pergola structures become more

Zhongtuo Industrial Cable Tray Roll Forming Production Line Zhongtuo Cable Tray Roll Forming Machine is

Full Automatic Steel Supermarket Shelves Storage Rack Upright Pillar Roll Forming Machine Improve Warehouse Efficiency

Cable Ladder & Cable Tray Roll Forming Machine High-Efficiency Steel Side Rail Forming Machine for

STAY IN THE LOOP