Design Idea:

Full automatic:easy operation for finished roof sheet stacking.

Save labor

Provide customized:3m/6m/12m normal length stacker,can also customized for you use with your roofing tile machine.

Automatic Stacker for Metal Roofing Roll Forming Machine

With a stacker, sheets are protected from scratches all the while keeping your roll former in production. The sheets stay protected by sliding along the rollers and guides rather than each other. The pneumatic powered stacker arms are triggered by a photo eye which releases the panels and drops them onto the stacked sheets. The design of both stackers allows for minimal drop distance of the panel which is critical key to a successful stacker. The drop distance is normally four inches. The less distance the sheet has to drop, the more uniform the stacked sheets will be.

Once an order is compete, the discharge table transfers the order onto the C-frames for packaging, then returns back to the stacker to allow the rollformer to stay running. The discharge table is fully powered – in, out, up, down. This creates a higher production rate and in turn, makes your company more profitable.

| Automatic Stacker | |

| Main motor power | 2.2kw |

| Drive | pneumatic |

| material | 45# forge steel and quenched |

| Length of stacker | 6m/8m/12m |

| Weight of stacker | About 5 ton |

| Size of stacker | About 10000×1800×2000mm L x W x H |

| Color of stacker | Yellow and Blue or Customized |

| Power of stacker | by air compressor |

Container house frame making machine Australian specification standards shipping living container house frame making machine is

Specification Standards Shipping Living Container House Frame Making Machine The Australian specification standards shipping living

Stainless Steel & Aluminum Door Frame Making Machine The stainless steel and aluminum door frame

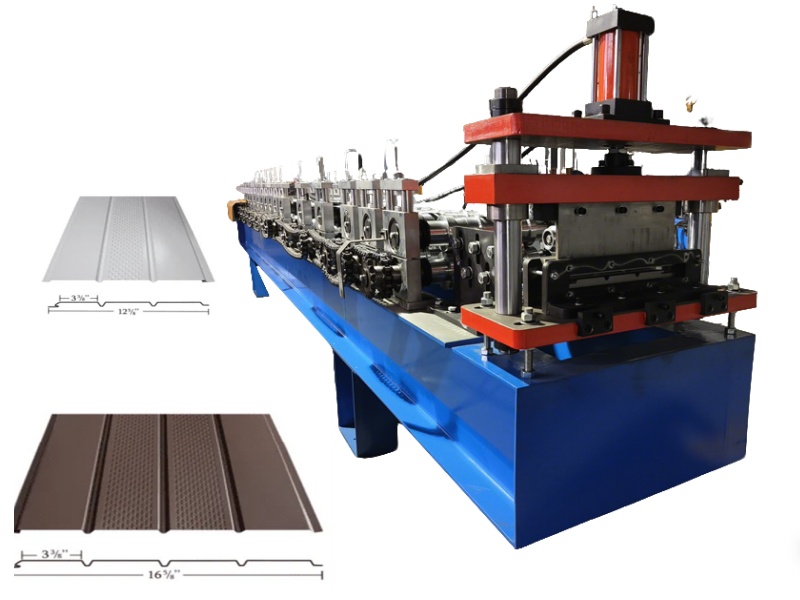

The ZTRFM Soffit Panel Roll Forming Machine is engineered for manufacturers who require fast, stable,

STAY IN THE LOOP