Grouting Keel Roll Forming Machine for Product Overview

The Grouting Keel Roll Forming Machine is engineered for manufacturing high-precision steel framing profiles. Utilizing galvanized or zinc-aluminum coated steel strips, this equipment shapes steel through continuous cold roll forming, resulting in strong and structurally sound grouting keels with excellent permeability and load-bearing performance.

These profiles serve as the ideal support framework for interior wall materials like gypsum boards, PVC boards, acoustic panels, and more. Thanks to its superior fire resistance, soundproofing, and insulation characteristics, the system is widely adopted across residential, commercial, and industrial construction sectors.

Grouting Keel Roll Forming Machine for Raw Materials

Applicable Materials: Galvanized steel (GI) or Aluzinc-coated steel

Processing Thickness: 0.6–1.5 mm

Grouting Keel Roll Forming Machine – Advantages

- Smart Automation: Integrated PLC control ensures continuous, consistent, high-efficiency production.

2. Broad Application Range: Ideal for commercial buildings, hospitals, high-rises, and more.

3. Performance Excellence: High strength, thermal/sound insulation, fire resistance, and compatibility with various board materials.

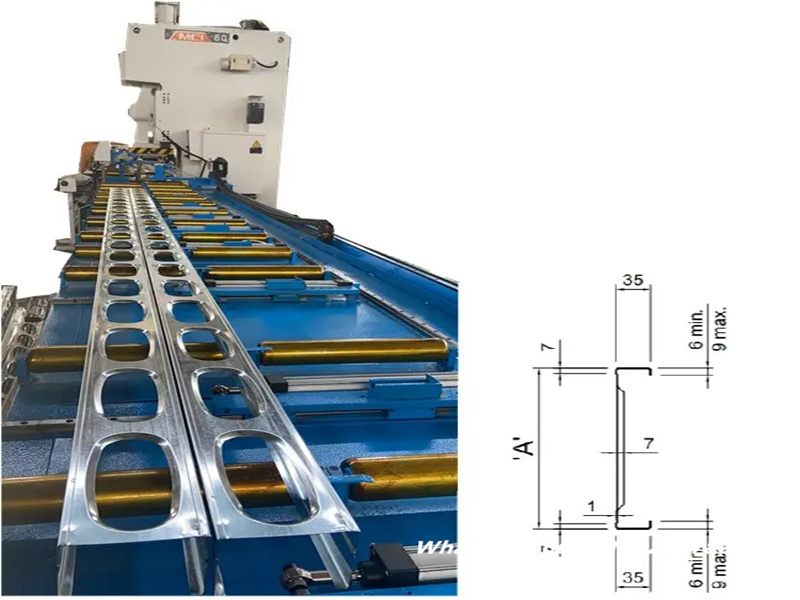

AFS Logicwall Structural Steel Stud Framing System for Profile Reference

(Standard drawing available upon request for customization or reference purposes)

Grouting Keel Roll Forming Machine Final Output & Workflow

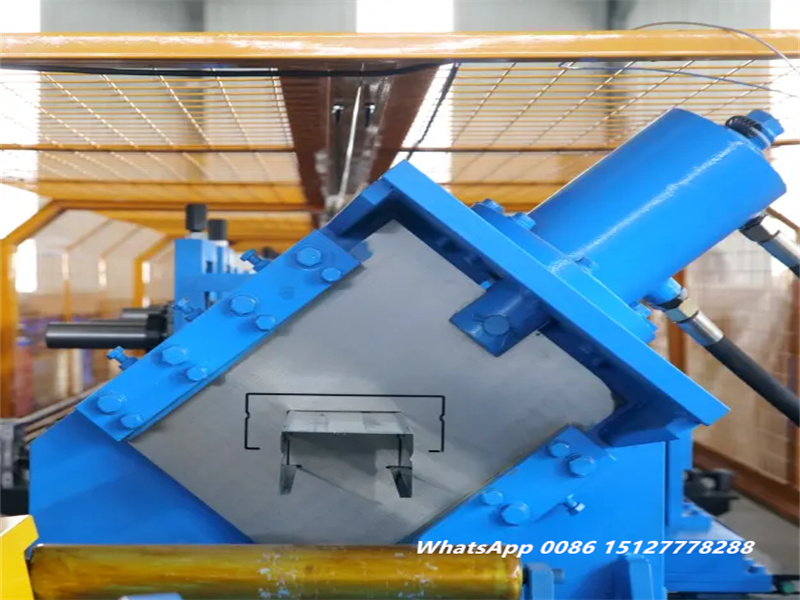

Process Flow: Uncoiling → Feeding → Roll Forming → Hydraulic Cutting → Output Transfer → Automatic Collection

The entire system operates fully automatically, minimizing human involvement while maximizing efficiency and consistency.

AFS Logicwall Structural Steel Stud Framing System for Key Components

- 3T Hydraulic Decoiler – Vertical setup with braking function

2. Forming Unit – Memorial archway frame with 17 stations, Ø70mm hardened shafts, dual 11kW motors

3. Hydraulic Cutting Section – Cr12 hardened blades for accurate cuts

4. Conveyor Table & Discharge System – Includes 6-meter rack and 11kW pump station

5. Electrical Control System – Delta PLC with touch screen, Schneider components, Omron counter, safety features

6. Punching Section – 8.8-ton Yangli press with 6 mold sets

AFS Logicwall Structural Steel Stud Framing System for Typical Applications

Non-load-bearing wall systems in homes and offices

Fill-in partitions for steel or concrete frame buildings

Fireproof separation walls in workshops

Interior insulation partitions for cold storage facilities

Popular in civil buildings, textile factories, hospitals, schools, and commercial centers

The ZTRFM heavy-duty coil recoiler is engineered for handling narrow-width and light-gauge strip materials, ensuring

The metal coil slitting and recoiling machine is designed for processing narrow-width strips with high

High-Precision Coil Embossing Machine for Decorative and Structural Metal Applications As a trusted coil embossing

Ridge cap Roll Former-12” universal Ridge cap Ridge Cap Roll Former – Hems both

STAY IN THE LOOP