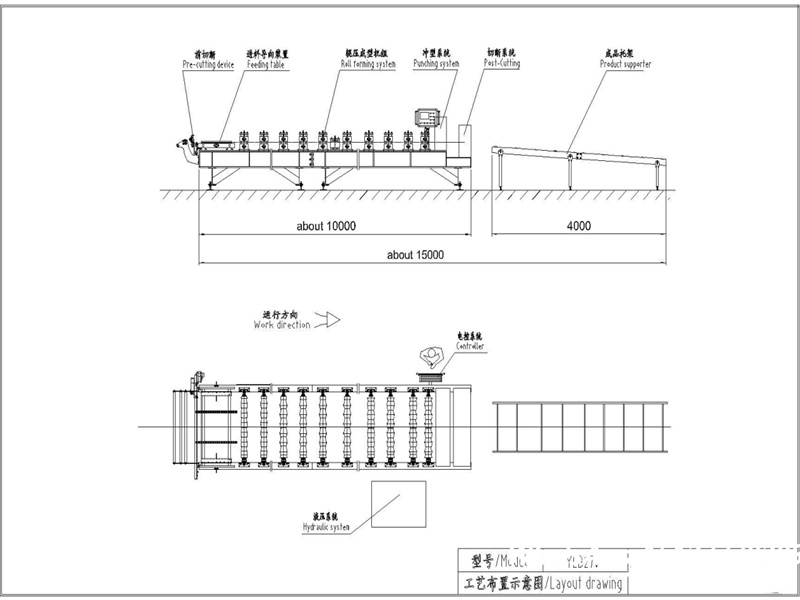

The Glazed tile roof panel rolling forming machine by Cangzhou ZTRFM delivers rapid, high-precision fabrication of coated metal roofing panels. Built on the ZTRFM platform with CE and ISO endorsements, it handles 0.4–0.6 mm PPGI/GI or G550 steel at speeds up to 20 m/min. An integrated decoiler and hydraulic shear streamline production, while hardened tooling and automated mold changes minimize downtime. Supplied nude with anti-oil coating in approximately 45 working days, this line—backed by flexible L/C or T/T payment terms and a two-year warranty—can produce up to 30 sets monthly, making it ideal for high-volume roof panel fabricators worldwide.

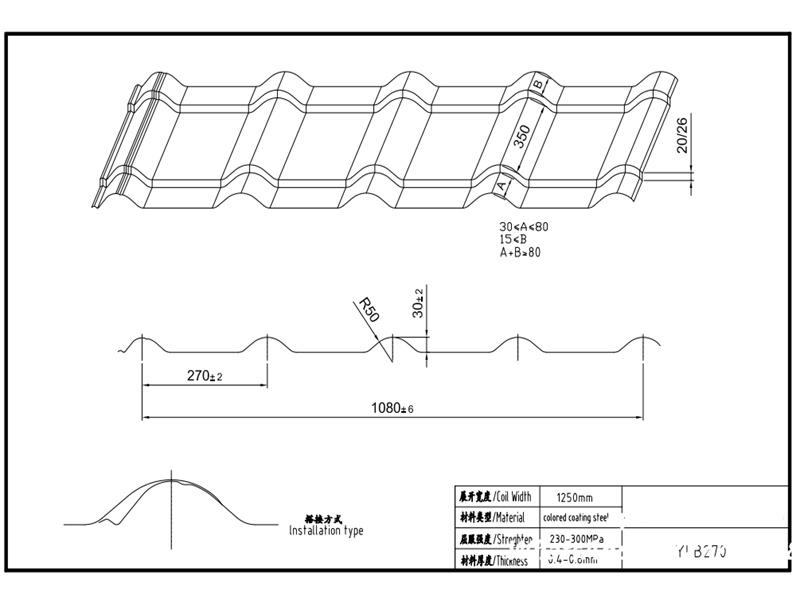

The Drawing Profile

Glazed tile roof panel rolling forming machine for Enhanced Feeding & Conveying

Durable PU Belts: Wear-resistant belts ensure smooth panel transport at full speed.

Vibratory Strip Feeder: Evenly distributes coils, reducing jams and setup time by over 15%.

Adaptive Pressure Rollers: Automatically adjust to sheet thickness, minimizing edge distortion.

Glazed tile roof panel rolling forming machine for Precision Molding & Fast Tooling Changes

Premium CNC-Machined Dies: GCr12MoV molds with mirror-finish deliver flawless panel surfaces.

Hydraulic Quick-Release System: Change mold sets in under 10 minutes to cut downtime.

Automated Lubrication: Programmable oil-mist nozzles extend tool life by 20%.

Glazed tile roof panel roll forming machine for Core Specifications

| Specification | Detail |

| Model | ZTRFM |

| Panel Thickness | 0.4–0.6 mm (PPGI/GI) or G550 |

| Max Forming Speed | 20 m/min |

| Roll Stations | 18 passes |

| Shaft Diameter | 70 mm |

| Main Motor | 11 kW |

| Hydraulic Power Unit | 4 kW |

| Control System | Delta PLC with 7″ touchscreen |

| Decoiler Capacity | Manual or hydraulic, 3 T |

| Cutting Method | Hydraulic shear, ±1 mm accuracy |

| Conveyor Belt | PU abrasion-resistant with feeder |

| Mold-Change Mechanism | Fully automated quick-release tooling |

| Packaging | Nude frame with anti-oil coating |

| Lead Time | ≈45 working days |

| MOQ | 1 set |

| Payment Terms | L/C or T/T |

| Warranty | 2 years |

| Certifications | CE, SGS |

| Monthly Capacity | 30 sets |

Glazed tile roof panel rolling forming machine for Continuous Cutting & Stacking

Non-Stop Hydraulic Shear: 4 kW unit cuts panels up to 6,000 mm without stopping the line, maintaining ±1 mm precision.

Flexible Stacking Solutions: Manual run-out tables or motorized stackers align panels for packaging.

Glazed tile roof panel rolling forming machine: Control & Upkeep

Intuitive Delta PLC Interface: 7″ touchscreen stores recipes, supports multiple languages, and enables remote diagnostics.

Modular Frame Construction: Bolted H-beam sections simplify assembly and future upgrades.

Comprehensive Support Package: Two-year parts warranty and lifetime technical assistance.

The ZTRFM heavy-duty coil recoiler is engineered for handling narrow-width and light-gauge strip materials, ensuring

The metal coil slitting and recoiling machine is designed for processing narrow-width strips with high

High-Precision Coil Embossing Machine for Decorative and Structural Metal Applications As a trusted coil embossing

Ridge cap Roll Former-12” universal Ridge cap Ridge Cap Roll Former – Hems both

STAY IN THE LOOP