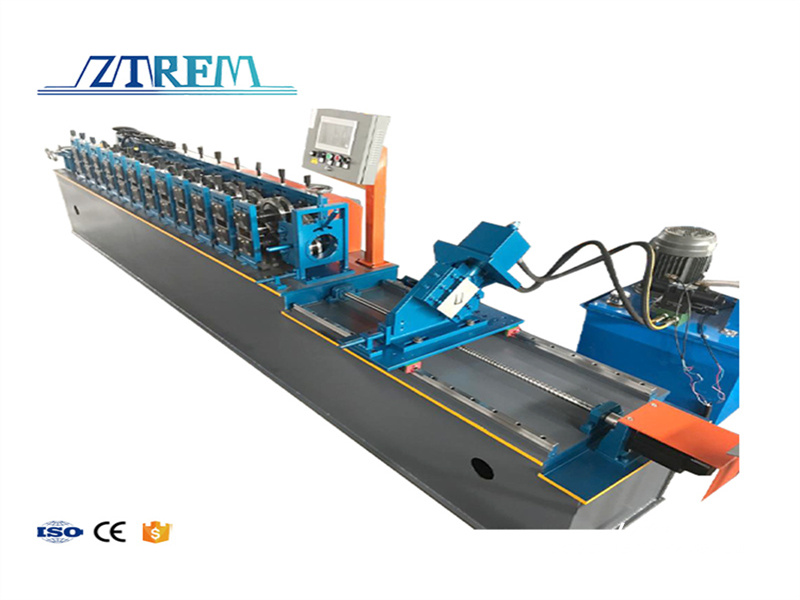

Door Guide Rail Roll Forming Machine

A Garage Door Guide Rail Roll Forming Machine continuously shapes flat steel strip into U-shaped guide rails used on rolling shutter doors. With a fully automated production line—including decoiler, pay-off, roll stands, hydraulic cutter, and stacking table—this machine delivers high-precision rails at speeds up to 60 m/min, ideal for mass production.

Technical Specifications of Door Guide Rail Roll Forming Machine

Material Thickness: 0.3 – 1.2 mm cold-rolled steel, galvanized, aluminum, or GI coils

Coil Capacity: Ø 508 – 610 mm ID, up to Ø 1500 mm OD; 3 – 5 ton hydraulic decoiler

Forming Stations: https://youtu.be/4LVFok8Dl2c?si=1l4R7txPIo9sNknQ12 – 16 roll-stand units (customizable)

Drive System: Decelerating motor with chain transmission; optional servo drive

Shearing: Hydraulic or flying shear for burr-free, precise cuts

Power Supply: 380 V, 50 Hz, 3-phase (customizable)

Machine Dimensions: Approx. 9 m (L) × 1.5 m (W) × 1.5 m (H)

Working flow:

Uncoiling — Feeding — Roll Forming — PLC Controlling — Hydraulic Pressing — Length to Cutting — Receiving

Key Features of Door Guide Rail Roll Forming Machine

High Production Speed: Adjustable roll-forming at 20/30/40/50/60 m/min with non-stop flying shear and auto-stacking.

Flexible Profile Changeover: Cassette-type platform and quick-change base accommodate multiple guide-rail profiles.

Heavy-Duty Construction: Rigid welded frame, 45# chromium-hardened rollers, 70 mm diameter shafts, and robust gearbox ensure accuracy and longevity.

Intelligent Control: PLC or CNC control system with touchscreen HMI, encoder-based length measurement, and optional Siemens or Panasonic electronics.

Applications –This guide rail roll forming machine produces rails for:

Rolling garage and commercial shutter doors

Industrial sliding doors and gate tracks

Elevator guide rails and rail-mounted equipment

Custom U-channel and C-section profiles

Precautions before using the new machine

When using the machine for the first time, after installing it and testing it with no load, pay attention to the following matters before online production:

- Before using the machine, add hydraulic oil from the oil station, add 46# gear oil to the automatic refueling device attached to the leveler, and set the refueling time.

- Check whether the transmission screw of the whole machine chain, guide rail, guide rod, and stacking rack has grease. If there is no or insufficient grease, add grease and then start production online to ensure the service life of the machine.

- Replace the plug screw with air hole on the reducer before using.

- Its precise, continuous operation minimizes scrap and reduces manual labor, making it a cost-effective solution for door, gate, and elevator manufacturers.

Full-Automatic T18/T35 IBR Roofing Sheet Roll Forming System with Dual-Layer Capability This advanced roll forming

LED Light Box Profile Roll Forming Machine The Component Specifications of this roll forming system

1100 Series High-Speed Automated Roll Forming Line Integrated Production Line Configuration Manual Decoiler → Roll Forming Unit → PLC

This machine manufactures roofing panels featuring single snap-lock seams, designed for rapid assembly without the

STAY IN THE LOOP