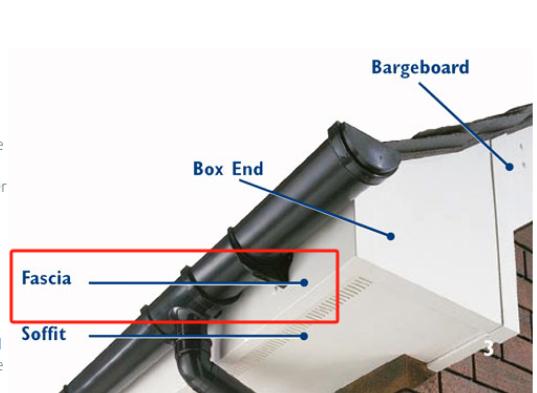

Fascia boards are the boards you see running along the lower edge of a roof, right where the roof meets the outer walls of a house. Some people call this the roofline, but most folks just call it the fascia since it’s the part that holds the gutter. Not everyone is familiar with these construction terms, so here’s a quick explanation.

You might come across terms like uPVC, PVCu, and PVCue. These refer to different types of PVC fascia boards, soffits, and bargeboards. PVC stands for polyvinyl chloride, which is a type of plastic. The “u” means unplasticised, which means it’s rigid (unlike the soft plastic used in kids’ toys). The “e” means expanded, meaning it’s foamed to make it lightweight but strong and thicker than regular PVC boards.

Fascia Board Basics

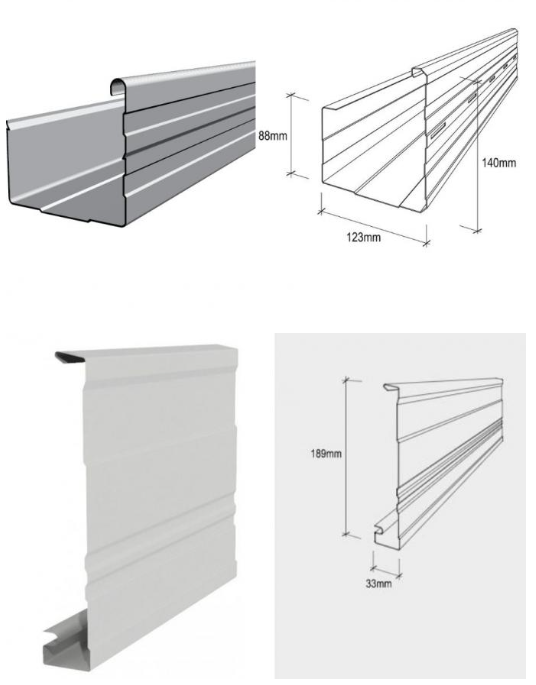

The fascia board itself is the long board that runs along the bottom edge of the roof. It’s attached to the lower ends of the roof trusses and supports the bottom row of roof tiles. It also has to hold up all the guttering. This is an important job, especially when it rains hard. Imagine a typical three-bedroom house roof collecting and sending several gallons of water per second into those gutters during a storm.

Machine Specifications of Fascia Board Roof Roll Forming Machine

– Profile: Fascia gutters

– Coil width: 14 inches

– Forming speed: 70 to 80 feet per minute

– Material thickness: Aluminum

– Machine weight: About 7 tons

– Machine footprint: 31 feet

– Main power: 8 HP

– Motor: 240V, 3-phase, 60Hz

– Drive system: Chain drive

– Stations: 24

– Cutting type: Electric shear

– Control system: Delta CNC

– Safety features: Safety covers and emergency stops

– Shipping location: Orlando, Florida

Overview Fascia Board Roof Roll Forming Machine

A fascia gutter roll forming machine is built to produce fascia gutters, which are key parts of a building’s drainage system. They help channel rainwater away from the roof and protect the building’s structure. These gutters are usually installed along the edge of the roof, right under the fascia board.

This machine shapes metal into consistent gutter sections using roll forming. Here’s how it works in simple steps:

– A coil of metal, usually aluminum or steel, is loaded onto the machine’s feeder.

– The metal runs through rollers that shape it into the gutter profile, adding the right bends and folds.

– A cutting system cuts the formed gutter to the right lengths, making sure each piece is consistent.

– Some machines can even add extra features like end caps or special bends.

– Finished pieces are stacked or packaged for easy transport.

Using a roll forming machine for fascia gutters makes production fast, reliable, and consistent. It’s perfect for manufacturers and contractors who need different lengths and styles for various projects.

General Information Fascia Board Roof Roll Forming Machine

All our machines are assembled at our Orlando, Florida, facility. Every machine comes with a one-year warranty that covers both parts and labor. We can also build machines to meet your specific profile and size requirements.

Please keep in mind that Roll Forming Machines LLC doesn’t offer direct financing. However, we can put you in touch with leasing companies that can help you finance your equipment. We’re not affiliated with any of these companies.

If you’d like a quote or have questions, please fill out the contact form below.

Technical Specifications of Fascia Board Roof Roll Forming Machine

– Weight: About 4000 kg

– Size: Approximately 6 meters long by 1 meter wide by 1.5 meters high

– Color: Main color blue, with yellow safety markings

– Suitable raw materials: PPGI and PPGL coils

– Thickness: 0.3 to 0.8mm

– Coil width: 610mm

– Yield strength: 235MPa

Main Technical Details of Fascia Board Roof Roll Forming Machine

– Diameter of forming roller shafts: 55mm

– Forming speed: 15 to 20 meters per minute

– Roller material: No.45 steel with chrome coating

– Cutter material: CR12 mold steel, heat-treated

– Control system: PLC with an inverter

– Main motor power: 4 kW

– Hydraulic motor power: 2.2 kW

The ZTRFM heavy-duty coil recoiler is engineered for handling narrow-width and light-gauge strip materials, ensuring

The metal coil slitting and recoiling machine is designed for processing narrow-width strips with high

High-Precision Coil Embossing Machine for Decorative and Structural Metal Applications As a trusted coil embossing

Ridge cap Roll Former-12” universal Ridge cap Ridge Cap Roll Former – Hems both

STAY IN THE LOOP