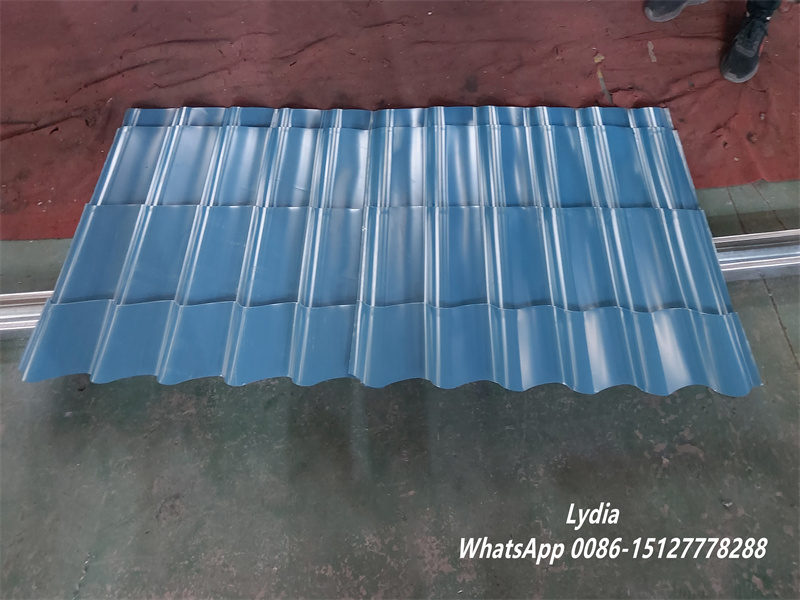

European Style Colour Steel Glazed Tile Roll Forming Machine

Product Overview European Style Glazed Tile Roll Forming Machine

The European Style Colour Steel Glazed Tile Roll Forming Machine is a high-efficiency production line designed to manufacture aesthetically appealing and durable colour steel glazed tiles in the European style. Through a fully automated forming and cutting process, it transforms metal coils into precision-formed tile sheets with a classical European appearance. It integrates features such as gearbox transmission, mold-based decorative cutting, and PLC smart controls to deliver high speed, low labor intensity, and stable output quality.

Key Advantages of European Style Glazed Tile Roll Forming Machine

- Enhanced Production Speed

Gearbox transmission allows forming speeds up to 10m/min, optimizing the cycle time for pressing and cutting.2. Elegant European-Style Tile Edges

Mold-based cutting creates classical decorative edges that mimic traditional European ceramic tile aesthetics.3. Highly Automated System

Equipped with a hydraulic decoiler and automatic stacker, the machine minimizes manual operation while increasing overall efficiency.

Machine Components and Specifications European Style Glazed Tile Roll Forming Machine

Hydraulic Decoiler

– Capacity: 5T

– Coil Inner Diameter: 450–550mm

– Coil Outer Diameter: 1500mm

– Coil Width: 1250mm (customizable)

– Hydraulic Power: 5.5kW

Feeding Section

– Protective rubber rollers to avoid scratching the tile surface

– Handwheel adjustment for various coil thicknesses and platform widths

– Inner bearings to protect the tile edges during feeding

Roll Forming System

– Roller Material: 45# steel with chrome coating (0.05mm) for corrosion resistance

– Shaft Material: 45# steel, tempered

– Forming Stations: 16

– Shaft Diameter: Φ80mm

– Structure: Rigid vertical arch frame

Transmission System

– Gearbox with bevel gear design

– Gear Material: 20CrMnTi

– Gearbox: Cast iron

– Chain drive between stations, one-to-one gear connection

– Benefit: Boosts speed directly after tile pressing and cutting

Hydraulic Cutting System

– Blade Material: Cr12, hardened

– Hydraulic Power: 7.5kW

– Cutting Tolerance: ±1mm

– Fan-cooled oil pump for system stability

PLC Control System

– Main PLC: Delta (Taiwan)

– Inverter: Delta

– Encoder: Omron

– Capabilities: Full automation for tile length and quantity management

The ZTRFM heavy-duty coil recoiler is engineered for handling narrow-width and light-gauge strip materials, ensuring

The metal coil slitting and recoiling machine is designed for processing narrow-width strips with high

High-Precision Coil Embossing Machine for Decorative and Structural Metal Applications As a trusted coil embossing

Ridge cap Roll Former-12” universal Ridge cap Ridge Cap Roll Former – Hems both

STAY IN THE LOOP