Downspout Pipe Roll Forming Machine Tube and Pipe Roll Former

Tube and Pipe Roll Former Rain Water Pipe Round Square Tube Forming Machine

Tube and Pipe Roll Forming Machine Technical Specifications

Tube and pipe roll forming machines have become essential tools in modern industrial production, offering a seamless and efficient method for manufacturing cylindrical components from flat metal strips..The tube roll forming process involves shaping flat metal coil into tubular structures by guiding it through a progressive series of roller stations. This method ensures consistent shape, diameter, and wall thickness throughout the tube or pipe, enabling manufacturers to meet exacting dimensional standards. This continuous forming process is ideal for producing long lengths of tube without requiring additional welding or reshaping

Tube Profile Options

Manufacturers can create a range of tube profiles using these machines, including:

Round Tubes: Ideal for railings, support poles, and transportation systems.

Square and Rectangular Tubes: Commonly used in building facades, office furniture, and framework applications.

Seamed/Welded Pipes: Employed in fluid systems, automotive exhausts, and mechanical structures requiring enclosed flow channels.

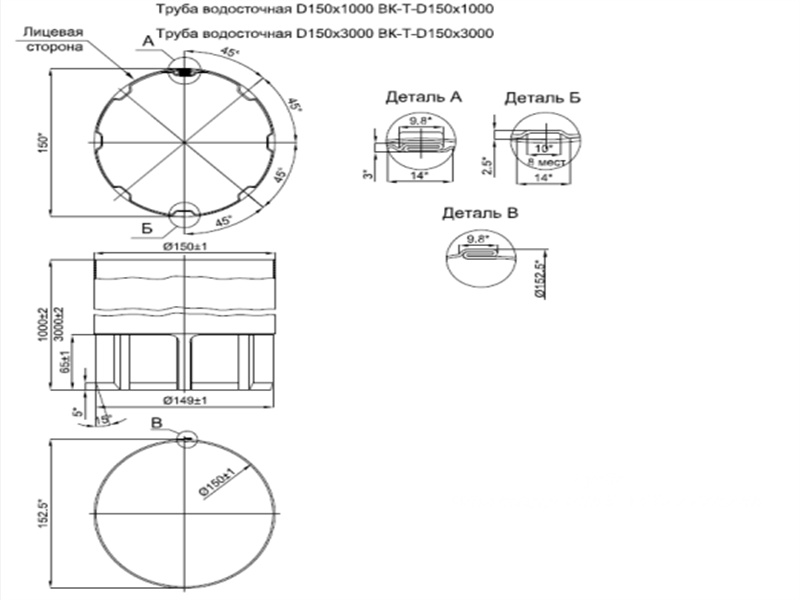

Technical Parameters of Rain Water Pipe Round Square Tube Forming Machine

Raw material: GI & PPGI, yield stress: 300–420 N/mm².

Material thickness: 0.35–0.55mm

Blank width: 493mm with protective film (30–40μm)

Adjustable cutting length

Operating mode: 24×7

Speed: ≥12 m/min

Part 1: 3T Decoiler

Supports both manual and automatic operation. Auto-adjusting speed synchronized with line speed. Load capacity: 3T, Inner diameter: 480–650mm, Coil width >500mm. Electrical reversing and defrosting are supported.

Part 2: Main Roll Former

Feeding rollers, 24 horizontal rolling stations + vertical rollers, shaft Ø70mm, 45# steel rollers with chrome coating, Steel welded base (350# H beam), Transmission: dual chain drive with cover. Speed: 0–12 m/min.

Tube and Pipe Roll Former Rain Water Pipe Round Square Tube Forming Machine

Part 3: PLC Control System

Delta brand PLC, frequency converter, touchscreen interface, multi-language support. Includes batch programming, length tracking, service logs (8–12 months storage). Electrical parts: Schneider & Omron.

Tube and Pipe Roll Former Rain Water Pipe Round Square Tube Forming Machine

Part 4: Cutting System

Electro-mechanical guillotine system, 4kW motor, GB-Cr12 blades, ±1mm/3m cutting accuracy. Protective structures for chain/sprockets, optical ruler for length tracking, high surface integrity requirements.

Engineered by Zhongtuo for Precision and Surface Protection As patio and pergola structures become more

Zhongtuo Industrial Cable Tray Roll Forming Production Line Zhongtuo Cable Tray Roll Forming Machine is

Full Automatic Steel Supermarket Shelves Storage Rack Upright Pillar Roll Forming Machine Improve Warehouse Efficiency

Cable Ladder & Cable Tray Roll Forming Machine High-Efficiency Steel Side Rail Forming Machine for

STAY IN THE LOOP