Recently, Zhongtuo Roll Forming Machinery successfully delivered and commissioned a color steel tile production line equipped with a 12m automatic stacker in the Dominican Republic. The customer spoke highly of the machine’s performance, reliability, and innovative design, recognizing it as an advanced method for roofing sheet production.

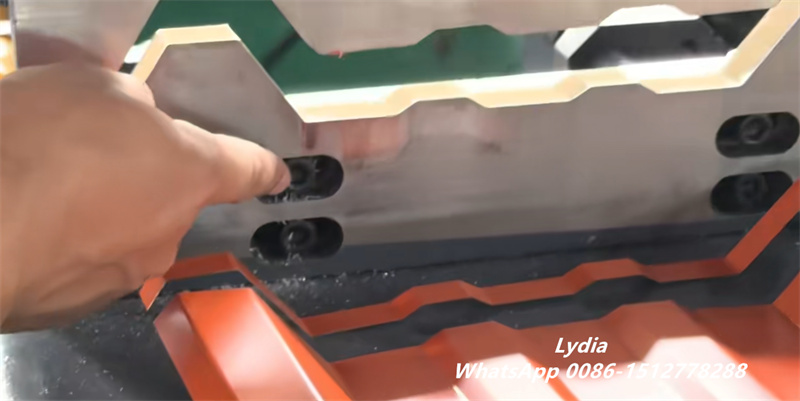

Another highlight lies in the double-hole embedded cutting system. Both the upper and lower blades are inset, and the bolts are deeply recessed. This design provides three major advantages:

-

Bolts are protected from direct force, enhancing safety and stability.

-

Blades, even after years of use, can be removed and reground on a surface grinder to restore their sharpness.

-

With the recessed bolt design, blades can be re-sharpened multiple times, extending their service life significantly.

The production line is designed with multiple innovative features to improve efficiency and ensure product quality. The automatic stacking system includes rubber protection blocks to safeguard materials, automatic alignment to keep stacks neat, and a smart sliding track that allows sheets to fall smoothly into position. Each stack can be arranged in sets of ten sheets, which can be offset easily, ensuring consistent and safe handling. An integrated automatic conveyor system further enhances production efficiency.

In addition, Zhongtuo has equipped the production line with a power-driven telescopic conveyor, allowing both long roofing sheets and short profiles to be transported seamlessly. The cutting system adopts a double-hole embedded blade design with deeply recessed bolts. This design not only prevents bolts from bearing direct force but also allows blades to be removed and re-sharpened repeatedly on a surface grinder, significantly extending service life. With the support of a spare blade set, the system ensures long-term, even lifetime usage.

The color steel tile roll forming machine also integrates advanced roller forming technology, precise counter systems, and carefully engineered details, highlighting Zhongtuo’s dedication to quality and innovation. These features collectively make the equipment a highly reliable choice for large-scale roofing sheet production projects.

Metal Roof Wall Roll Forming Machine

While some competitors have attempted to imitate aspects of this technology, Zhongtuo continues to lead by focusing on product quality, equipment performance, and customer service. This project not only strengthens Zhongtuo’s presence in the Dominican market, but also demonstrates the company’s commitment to delivering high-efficiency roll forming lines worldwide.

With this successful installation, Zhongtuo once again proves its reputation as a trusted roll forming machine supplier, delivering advanced and durable solutions for the global construction industry.

Metal Roof Wall Roll Forming Machine

While some peers may imitate certain aspects of our designs, we welcome healthy competition as an opportunity for mutual progress. We believe that continuous improvement in product quality, technical innovation, and service capacity will always be the true hallmark of our brand.

Engineered by Zhongtuo for Precision and Surface Protection As patio and pergola structures become more

Zhongtuo Industrial Cable Tray Roll Forming Production Line Zhongtuo Cable Tray Roll Forming Machine is

Full Automatic Steel Supermarket Shelves Storage Rack Upright Pillar Roll Forming Machine Improve Warehouse Efficiency

Cable Ladder & Cable Tray Roll Forming Machine High-Efficiency Steel Side Rail Forming Machine for

STAY IN THE LOOP