Color Steel Roof Tile Roll Forming Machine High Precision & Efficient Production Line

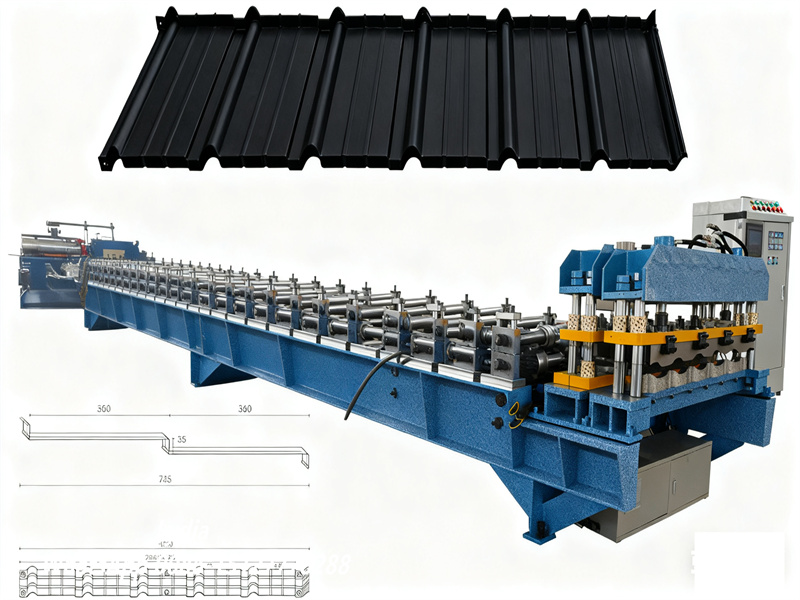

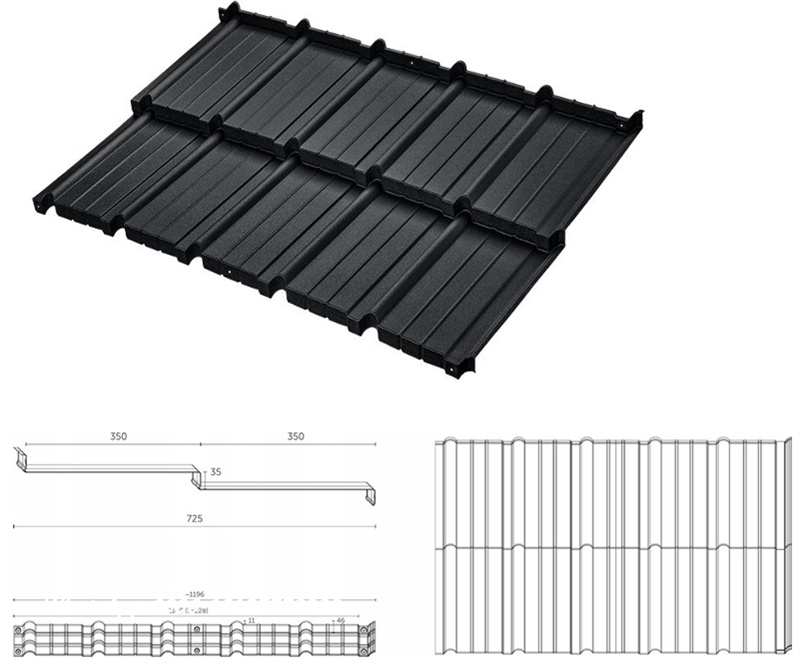

The Color Steel Roof Tile Roll Forming Machine is specially designed for producing high-quality colored steel roofing sheets used in modern industrial and residential construction. The machine adopts advanced PLC control technology, hydraulic cutting system, and precision roller forming structure, ensuring stable performance, smooth operation, and long service life.

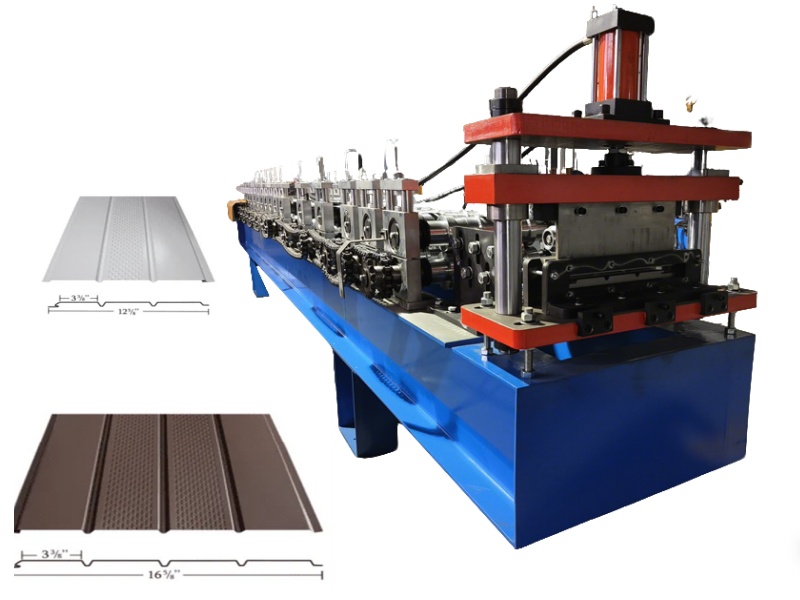

Roof Tile Roll Forming Machine

It is an ideal roofing tile for production with high efficiency, beautiful profile appearance, and accurate dimensions.

Technical Specifications of Roof Tile Roll Forming Machine

| No. | Item | Specification | Remarks |

|---|---|---|---|

| 1 | Suitable Material | Type: PPGI, PPGL | |

| Width: 1250 mm | |||

| Thickness: 0.4–0.6 mm | |||

| Yield Strength: 230–300 MPa | |||

| 2 | Production Speed | About 7–9 m/min | Based on actual design |

| 3 | Roller Material | No.45 steel, hard chrome coated | |

| 4 | Number of Roller Stations | About 21+1 | |

| 5 | Cutting Type | Hydraulic cutting | |

| 6 | Power Supply | 380V, 50Hz, 3-phase | |

| Total Power | Approx. 21.55 kW | Based on actual design | |

| 7 | Machine Dimensions | As per drawing |

Machine Components of Machine

| No. | Name | Quantity | Description |

|---|---|---|---|

| 1 | Main Forming Part | 1 | Including pre-cutting, guiding, roll forming, punching & cutting |

| Pre-Cutting Device | 1 | Cuts material before forming | |

| Guiding Device | 1 | Controls sheet position and width | |

| Roll Forming System | 1 | Straight guide post type structure | |

| Punching & Cutting Device | 1 | Cr12 blade, quenched | |

| 2 | Receiving Rack | 1 | 4m manual support |

| 3 | PLC Control System | 1 | Touch screen + buttons, Mitsubishi inverter |

| 4 | Hydraulic Station | 1 | With accumulator, China top brand valves |

Detailed Component Description

1. Pre-Cutting Device

Used for cutting the steel sheet to the required size before forming, ensuring material utilization and smooth feeding.

2. Guiding System

Equipped with guiding rods and sliding blocks to control the width and position of the steel sheet, ensuring precise feeding and stable operation.

Roof Tile Roll Forming Machine

Roof Tile Roll Forming Machine

3. Roll Forming System

- Frame: Welded structure, surface sandblasted and coated.

- Rollers: Made of high-quality No.45 steel with hard chrome plating.

- Support Type: Straight guide post structure.

- Drive System: Servo motor drive, front and rear rollers driven by chain; partial upper and lower rollers by gears.

- Thickness Adjustment: Manual screw adjustment to adapt to different sheet thicknesses.

Roof Tile Roll Forming Machine

4. Punching & Cutting Device

- Cutting Blade: Cr12 mold steel, quenched, no waste cutting.

- Power Source: Hydraulic station.

- Punching Depth: Two optional depths—20mm or 26mm—adjustable by spacer change. Lower die can be lifted by hydraulic cylinder for easier replacement.

Roof Tile Roll Forming Machine

5. Receiving Rack

- For manual panel support.

- Total length: 4 meters.

Roof Tile Roll Forming Machine

6. Electric Control System

- Control Type: PLC + Frequency speed control.

- Functions: Set batches, sheet length, and quantities via HMI screen.

- Encoder System: Length measurement and counting function.

- PLC Brand: Mitsubishi (Japan).

Roof Tile Roll Forming Machine

7. Hydraulic Station

- Provides power for cutting and punching.

- Equipped with energy accumulator and high-quality valves.

- Stable and efficient hydraulic pressure supply.

Roof Tile Roll Forming Machine

Standard Accessories and Tools

| Category | Item | Quantity | Remarks |

|---|---|---|---|

| Main Machine | Pre-cutting device, guiding system, roll forming, punching & cutting, receiving rack, PLC cabinet, hydraulic station | Complete Set | |

| Tools | Hex wrench set, double-ended wrench, adjustable wrench, flat & cross screwdrivers | 1 set each | For maintenance |

| Accessories | Mini relay ×2, buttons ×3, selector switch ×1, coupling ×1, solenoid valve ×2, oil filter ×1 | — | Spare parts |

| Documents | Operation Manual ×1, Packing List ×1 | — | Provided with machine |

Applications of Roll Former

The machine is widely used for producing roofing tiles, wall panels, and decorative building sheets, suitable for industrial workshops, warehouses, and residential buildings.

It’s a reliable choice for metal sheet processing factories looking for efficiency, precision, and automation in production.

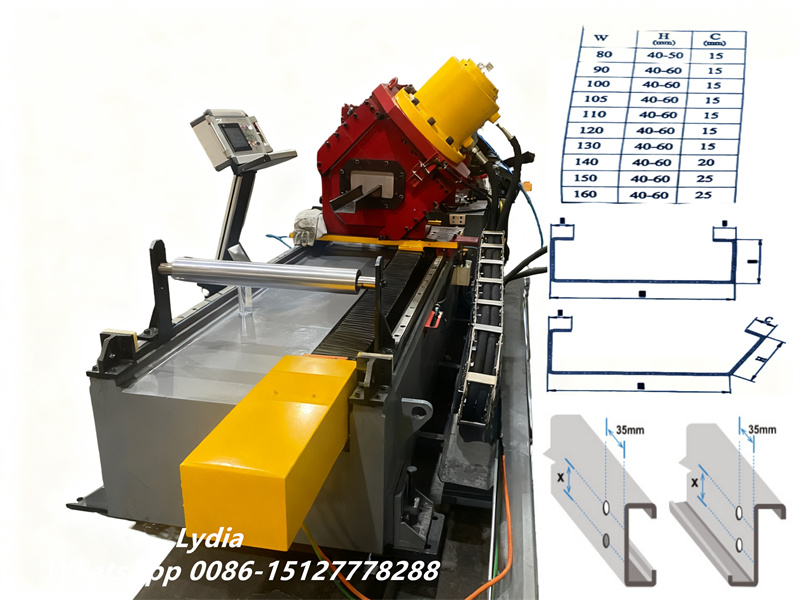

Stainless Steel & Aluminum Door Frame Making Machine The stainless steel and aluminum door frame

The ZTRFM Soffit Panel Roll Forming Machine is engineered for manufacturers who require fast, stable,

Cee & Zee Eave Struts Roll Forming Machine for Metal Buildings High-Performance Purlin Mill In

We are pleased to announce the successful delivery of our high-performance double-layer trapezoidal RIB metal

STAY IN THE LOOP